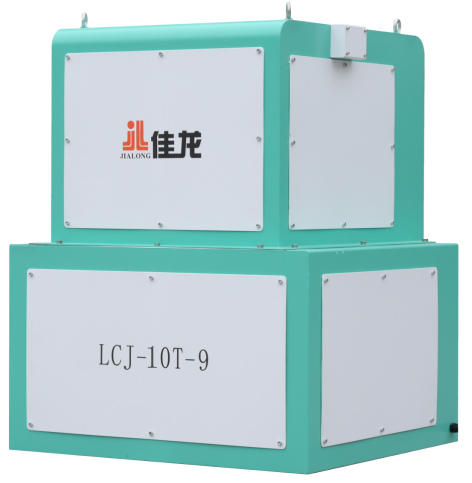

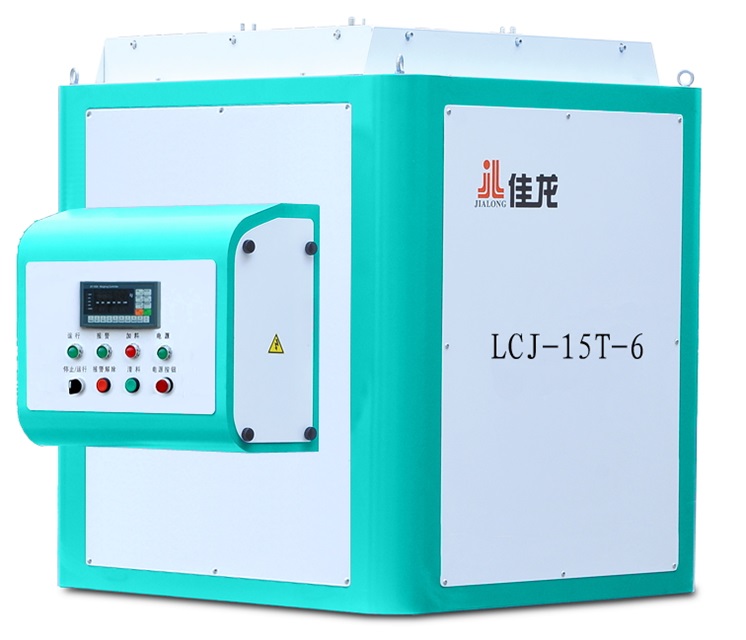

Rigorous testing for automatic metering packaging equipment, vacuum packaging machines, and robotic lines—ensuring global quality standards for every product.

Zhangzhou Jialong’s QC team conducting precision checks on automatic metering packaging equipment—upholding our quality promise.

Our Quality Control Center isn’t just a facility—it’s the backbone of Zhangzhou Jialong’s reputation. Staffed by highly trained QA specialists and equipped with top-tier testing gear, it ensures every piece of our packaging machinery (from vacuum models to robotic lines) meets the strictest global standards for performance, safety, and durability.

We don’t cut corners—quality starts with raw materials (like 304 stainless steel for vacuum machine chambers) and continues through every production step. In-process inspections catch issues early, while final checks verify everything from a vacuum packaging machine’s seal tightness to an automatic metering line’s accuracy.

Our lab runs targeted tests for every product: durability trials for robotic palletizing lines, vacuum degree tests for packaging machines, and safety compliance checks (ISO, CE) to meet global market rules. This data ensures our equipment works reliably—no matter where you operate.

We build quality into new designs, not just check it later. Our QC team works with R&D to test prototypes—like new automatic metering systems—identifying potential issues early. This cuts development time and makes sure new products live up to Jialong’s standards.

Every test result, every inspection note—we document it all in a secure database. This means full traceability for every machine (so you know exactly how your vacuum packaging line was checked) and gives us data to keep improving. We update our testing gear and processes regularly to stay ahead of industry trends.

When you buy Zhangzhou Jialong’s automatic metering, vacuum, or robotic packaging equipment, you’re getting a product tested to perfection. Let’s talk about how our quality standards can support your operations.