Efficient Paddy Weighing Flow Scale – 30 Ton/Hour Capacity

LCS-30: The Smart Weighing Solution for Growing Mills

In the world of grain processing, precision is profit. Our LCS-30 Paddy Weighing Flow Scale is expertly engineered for small to medium-sized facilities that require dependable accuracy without the industrial scale or cost of larger systems. It’s the perfect step-up for automating your workflow.

With a perfectly balanced capacity of 30 tons per hour, this flow scale provides the continuous, reliable data you need to manage inventory, guarantee product quality, and ensure every transaction is fair and transparent.

Model: LCS-30

Capacity: 30 Tons/Hour

Core Technology: Smart Cumulative Weighing

Key Advantages for Your Operation

Optimized Throughput

The 30 TPH capacity is ideal for matching the processing speed of small to medium rice mills and production lines, ensuring smooth, bottleneck-free operation.

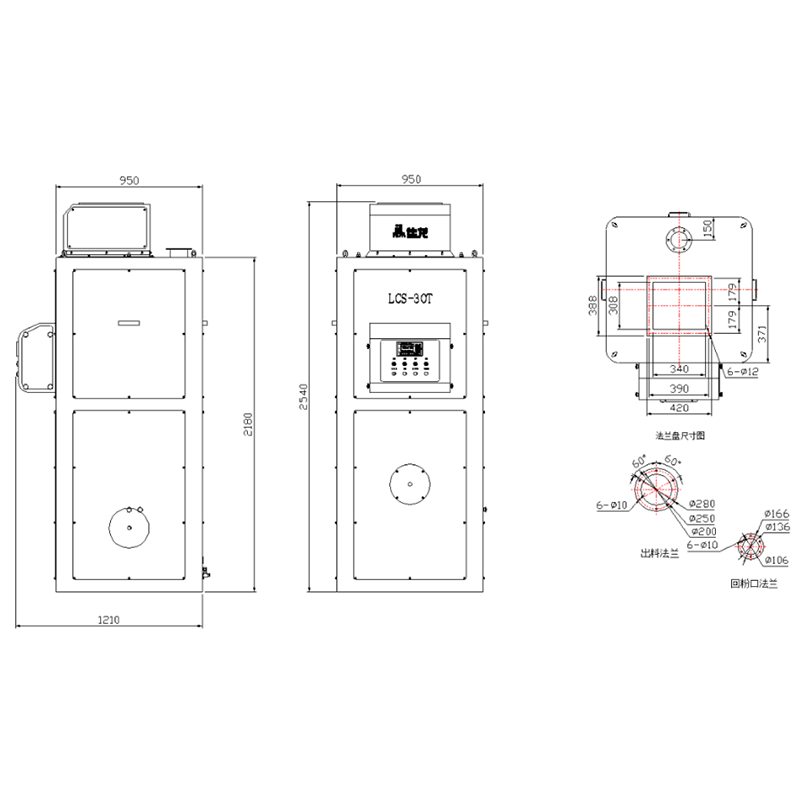

Compact & Easy to Install

Featuring an integrated, space-saving design, the LCS-30 can be retrofitted into existing production lines with minimal structural changes and disruption.

Reliable & Built to Last

Constructed with a fully sealed body and high-quality components, it is designed to withstand dusty environments, ensuring long-term reliability and low maintenance.

Intuitive Data Management

The user-friendly PLC controller and optional RS485/232 port allow for easy monitoring of flow rates, cumulative totals, and seamless data transfer to your systems.

Technical Specifications

| Parameter | Model: LCS-30 |

| Rated Weighing Capacity | 30 Tons/Hour |

| Weighing Accuracy | Dynamic Accuracy ≤ ±0.2% |

| Power Requirement | AC 220V/380V, 50Hz |

| Air Pressure | 0.4~0.6 MPa |

| Display | Touchscreen HMI Display |

| Communication Port | RS232/485 (Optional) |

Main Component Configuration

For the LCS-30 model, we select globally recognized components that offer the perfect balance of performance, durability, and value, ensuring reliable operation for medium-scale applications.

| Component | Brand / Supplier |

| Weighing Controller | China/General Measure |

| Power Switch | Taiwan/Meanwell |

| Low-Voltage Electricals (Button, Knob) | France/Schneider |

| Load Cell | China/ZEMIC |

| Pneumatic Elements (Cylinder, Solenoid Valve) | Taiwan/Airtac |

Ideal Application Scenarios

1

Receiving & Dispatch

Accurately measures incoming raw materials (paddy, corn) or weighs finished rice for dispatch, ensuring precise transaction records.

2

In-Process Monitoring

Place it within your production line to monitor the flow between stages, such as after cleaning or before milling, to calculate process yield.

3

Feed & Seed Blending

Control the ratio of ingredients in feed production or manage seed batching with a high degree of accuracy and repeatability.

4

Internal Inventory Transfer

Efficiently track the movement of grain between storage bins or departments for accurate internal accounting and stock management.

In-Depth Details

Working Principle

The LCS-30 operates on the principle of cumulative weighing to measure continuous material flow. Material first enters a buffer hopper, which then feeds a dedicated weighing hopper. Once the weighing hopper fills to a pre-set level, the inlet gate shuts, the controller captures the precise weight of the batch, and adds it to the cumulative total. The discharge gate then opens to release the material. This entire weigh-and-discharge cycle repeats automatically, providing an uninterrupted and highly accurate measurement of your total throughput.

Engineered for Your Environment

We understand the conditions of a working mill. The LCS-30 features a robust, fully enclosed carbon steel body to prevent dust from interfering with its high-precision sensors and pneumatic components. This durable construction ensures a long service life and consistent performance, giving you an excellent return on your investment. The energy-efficient design also helps keep your operational costs low.

Frequently Asked Questions (FAQ)

Q1: What kind of accuracy can I expect during daily operation?

A: The LCS-30 is engineered to maintain a dynamic accuracy of ±0.2% or better. This high level of precision minimizes product loss and ensures your production data is reliable for both internal accounting and external trade.

Q2: How difficult is it to install this flow scale into an existing plant?

A: Thanks to its compact, integrated design, installation is straightforward. It requires a relatively small vertical space and can typically be fitted into your existing conveyor system with minimal modification. We provide clear diagrams and support to guide your team.

Q3: Is the 30 TPH capacity sufficient for a growing business?

A: A capacity of 30 tons/hour is substantial, equivalent to 720 tons in a 24-hour day. It's an excellent choice for businesses that are scaling up, providing plenty of headroom for future growth without the significant upfront cost and space requirements of much larger industrial scales.