LCJ-10T-9 Precision Granular Blending Machine

LCJ Series Continuous Dosing Scale for Accurate Mixing

Elevate your production standards with the LCJ-10T-9, a specialized food blending machine engineered for precise, continuous dosing of granular materials.

As an ideal beans mixing machine, it excels at proportioning ingredients like rice, seeds, and pulses, ensuring recipe integrity with a throughput capacity of up to 10 tons per hour.

Primary Use: Continuous Ingredient Proportioning & Flow Control

Throughput: Up to 10 Tons/Hour

Static Accuracy: ±0.2%

Core Features

Optimized Throughput

Built for medium-to-large scale lines, this model provides a dependable single-channel output of up to 10T/h, balancing robust capacity with efficiency.

Superior Accuracy

Guarantees strict recipe adherence with a remarkable static accuracy of ±0.2%, supported by a real-time flow correction system for consistent output.

Intelligent Automation

Employs a wide 1:40 ratio range and an auto-adjusting discharge gate for masterful flow management, complemented by a one-button clearing for quick transitions.

Hygienic & Versatile Build

Its residue-free structural engineering and reliable dual feeding mechanisms ensure clean, stable operation suitable for a diverse range of granular products.

Technical Specifications

| Parameter | Model: LCJ-10T-9 | Model: LCJ-20T-9 |

| Capacity (Flow Rate) | 0.3 - 10 Tons/Hour | 0.5 - 20 Tons/Hour |

| Accuracy | ±0.2% | |

| Power Supply & Consumption | AC 220V, 50Hz, 30W | |

| Air Supply & Consumption | 0.4~0.6 MPa, 1 m³/h | |

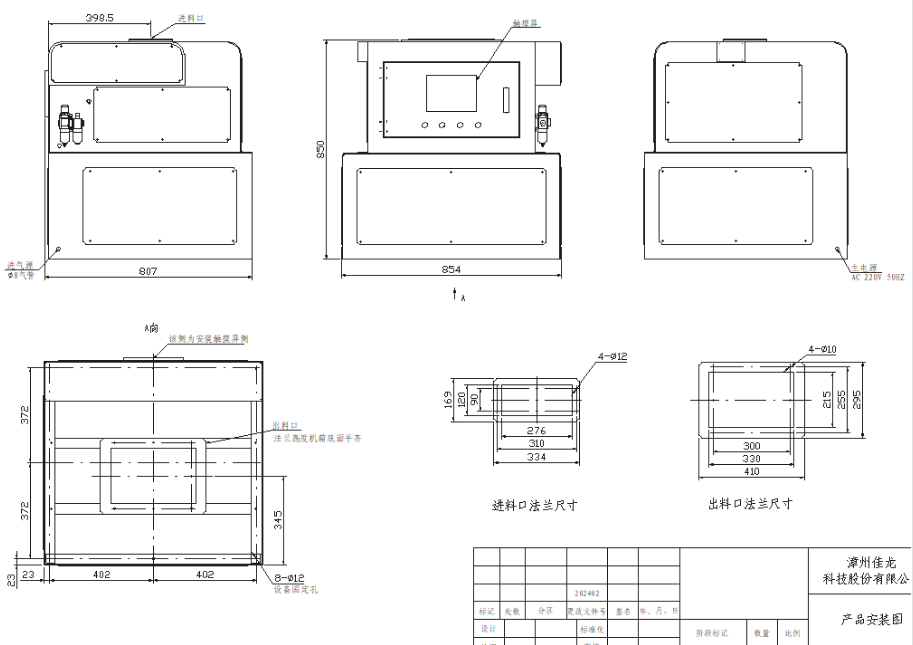

| Dimensions (L×W×H) | 854 × 807 × 850 mm | 854 × 807 × 1050 mm |

| Weighing Hopper Capacity | 23 Liters | 32 Liters |

| Working Temperature | 0 ~ 45°C | |

Note: Stated accuracy and flow rate are based on internal tests using round grain rice. Actual performance may fluctuate based on specific material characteristics, supply consistency, and environmental conditions.

Main Component Configuration

| Component | Brand / Supplier |

| Weighing Controller | China/General Measure |

| Power Switch | Taiwan/Meanwell |

| Button / Knob | French/Schneider |

| Load Cell | China/ZEMIC |

| Step Motor | Shenzhen/Leisai |

| Pneumatic Element | Taiwan/Airtac |

Industrial Applications

1

Multi-Ingredient Proportioning

An excellent beans mixing machine. Combine several units to craft custom blends of rice, pulses, and seeds with high formula precision.

2

In-Line Flow Regulation

Function as a flow measurement device, delivering a steady, controlled feed of material to subsequent equipment like packers or mills.

3

Recipe-Based Production

A key food blending machine for creating uniform animal feed mixes or food products by accurately dosing various dry components.

4

High-Precision Batching

Accurately measure and dispense large, predefined weights of material for filling bulk bags, totes, or for transferring to other systems.

In-Depth Details

Working Principle

The LCJ Series functions as a "loss-in-weight" continuous dosing scale. Material enters the machine's weighing hopper from a supply silo. An advanced controller constantly monitors the rate of weight reduction as the product discharges. Based on this live data, it modulates a stepper motor to adjust the discharge gate, maintaining a constant, user-defined flow rate (e.g., tons per hour). This dynamic feedback loop ensures superior accuracy in dosing and blending.

Our Commitment to Quality and Sustainability

We are committed to manufacturing industrial equipment that is both robust and responsible. The LCJ Series features a durable, non-residue construction for operational cleanliness and is built from premium materials for an extended service life. Its energy-efficient design, consuming only 30W, helps reduce operational expenses and environmental impact. By utilizing reliable, globally-sourced components, we provide a food blending machine you can trust, with every unit undergoing rigorous quality assurance and calibration prior to shipment.

Dedicated Customer Partnership

Application Expertise: Our engineers will collaborate with you to analyze your unique blending and flow control needs, ensuring the system is perfectly tailored to your materials and production targets.

Responsive Technical Service: We provide complete after-sales service, including comprehensive manuals, installation support, and remote access to our technical team for troubleshooting and optimization.

Reliable Spare Parts Supply: To maximize your plant's uptime, we keep a full inventory of all essential components, available for quick dispatch when needed.

Frequently Asked Questions (FAQ)

Q1: How do I blend different materials using this machine?

A: A blending system is formed by installing multiple LCJ units in parallel. Each machine is assigned to a specific ingredient and set to the desired flow rate. All the machines then discharge onto a shared collection conveyor, where the ingredients combine into your final, precisely mixed product.

Q2: What does "automatic flow correction" do for my production?

A: This feature provides constant self-regulation. The controller continuously checks for any deviation from the target flow rate caused by variations in material density or flowability. It then instantly corrects the discharge gate's opening, guaranteeing a stable and highly accurate output during the entire process.

Q3: How complex is the machine to operate?

A: It is designed for simplicity. The operator's main task is to set the primary goals, such as the target flow rate (in tons/hour) or the total batch quantity. The machine's intelligent controller automatically manages all the intricate real-time calculations and adjustments.