LCJ-8T-6 Precision Rice & Grain Blending Machine

LCJ-8T-6 Automated Continuous Flow Scale & Mixer

The LCJ-8T-6 offers a perfect fusion of precision and efficiency for industries like food processing, grain milling, and chemicals. It provides a reliable, automated solution for creating consistent, high-quality blends in continuous production lines.

This advanced rice blending machine employs an intelligent continuous dosing system to manage diverse granular materials, delivering superior accuracy with a stable throughput of up to 8 tons per hour.

Model: LCJ-8T-6

Capacity: Up to 8 Tons/Hour

Core Technology: Continuous Loss-in-Weight Feeding

Key Features

Efficient Production Flow

Engineered for consistent performance, this model delivers a steady output of up to 8 T/h, ideal for medium to large-scale blending and material dosing operations.

Uncompromising Accuracy

Our rice mixer uses a dynamic flow-rate correction system and a triple load-cell setup to guarantee high precision (≤0.5%) and immediate response to material variations.

Intelligent Operation

Features automated functions such as quantitative target batching, safety alarms, one-touch material clearing, and a data interface for integration into a central PLC system.

Hygienic & Adaptable Build

Designed with a smooth interior to prevent residue buildup, it allows for quick and easy cleaning. The dual feeding mechanism handles various granular materials with ease.

Technical Specifications

| Parameter | Model: LCJ-8T-6 |

| Capacity (Flow Rate) | 0.2 - 8 Tons/Hour |

| Accuracy | ≤0.5% |

| Power Consumption | 0.3 KW |

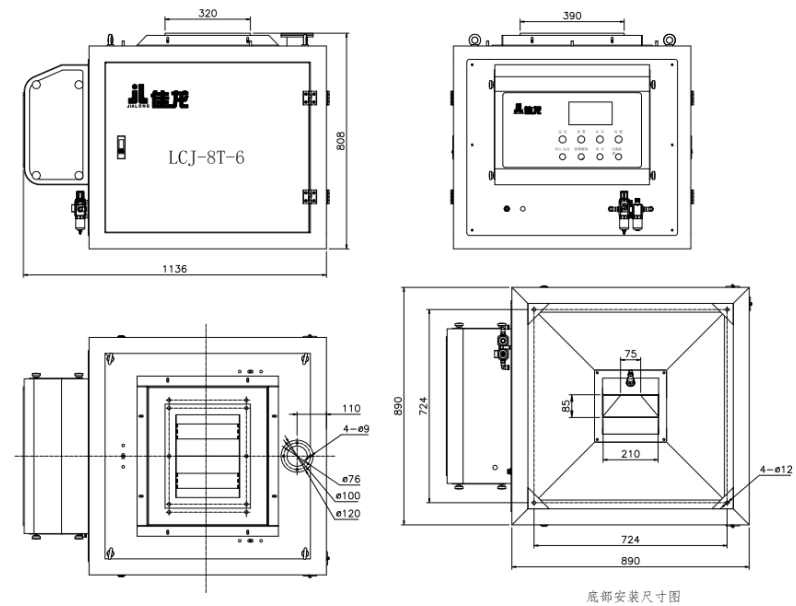

| Installation Dimensions (L×W×H) | 910 mm × 1150 mm × 1060 mm |

Main Component Configuration

| Component | Brand / Supplier |

| Weighing Controller | China/Zhiyuanda |

| Low-Voltage Electricals (Button, Contactor, etc.) | French/Schneider |

| Load Cell Sensor | America/Celtron |

| Power Switch | Taiwan/Meanwell |

| Gear Reducer | Taiwan/Ruiyong |

| Pneumatic Element | Taiwan/Airtac |

Common Applications

1

Crafting Precision Blends

As an excellent rice mixing machine, combine multiple units to formulate complex recipes for specialty grains, cereals, pet food, or other multi-component products.

2

Process Line Integration

Integrate this grains blending machine to ensure a steady, regulated material supply to vital downstream equipment like extruders, packaging machines, or coating drums.

3

Controlled Material Transfer

Use for accurately measured transfer of bulk materials between production stages, such as loading hoppers or filling silos with a pre-set total weight.

4

Quantitative Feeding

Accurately meter bulk ingredients into large industrial mixers, reactors, or cookers, ensuring recipe consistency for large-scale batch production.

In-Depth Details

How It Works

The LCJ-8T-6 is a sophisticated "loss-in-weight" feeder. It operates by continuously monitoring the rate of weight decrease in its onboard hopper as material is discharged. The system's controller constantly cross-references this real-time data with the user-defined flow rate (e.g., tons per hour). It then makes instant micro-adjustments to the discharge gate speed, ensuring the material output remains exceptionally stable and precise, making it a cornerstone for continuous mixing lines.

Built for Reliability

Our dedication to quality is evident in every aspect of this rice mixer. It is constructed for durability and consistent operation in demanding industrial settings. The hygienic, residue-resistant interior ensures product purity and facilitates rapid cleaning between batches. By incorporating globally recognized, high-quality components, we deliver a dependable system that optimizes productivity while maintaining a low power footprint (0.3 kW). Each machine is rigorously calibrated and tested before shipment to guarantee it meets our stringent performance criteria.

Our Service Commitment

Tailored Process Consultation: Our technical experts will collaborate with you to analyze your specific production needs and help configure the ideal blending or feeding solution to maximize your efficiency.

Complete Technical Assistance: We provide robust after-sales support, which includes user manuals, instructional videos, and direct remote access to our engineering team for seamless installation, operation, and troubleshooting.

Long-Term Partnership: Our support extends far beyond the initial sale. We are committed to offering lifetime technical service, ready to assist with any operational challenges or optimization needs throughout the machine's lifespan.

Frequently Asked Questions (FAQ)

Q1: What is the primary advantage of this continuous flow machine over a conventional batch mixer?

A: Batch mixers operate on a stop-and-start cycle, processing one fixed quantity at a time. This continuous flow machine, however, is built for non-stop production. It feeds material at a constant, precise rate, making it far more efficient and suitable for automated, large-volume manufacturing lines.

Q2: How do I blend multiple ingredients, for example, two types of rice and one type of bean?

A: Creating a multi-component blend is straightforward. You would arrange three individual LCJ-8T-6 units in a parallel setup. Each machine would be assigned one ingredient and set to its specific required flow rate. All three would then discharge simultaneously onto a collection conveyor, creating a perfectly mixed final product.

Q3: Why is a triple-sensor design important?

A: The triple-sensor (or triple load-cell) configuration creates a highly stable weighing platform that effectively resists external vibrations common in factories. This provides a cleaner, more reliable data signal to the controller, enabling it to make faster and more precise adjustments to the material flow for superior accuracy.