The automatic stand up pouch packing machine is in accordance with the conventional bagging process configuration, the entire production process a high degree of automation, in line with China GMP health standards;

Email More

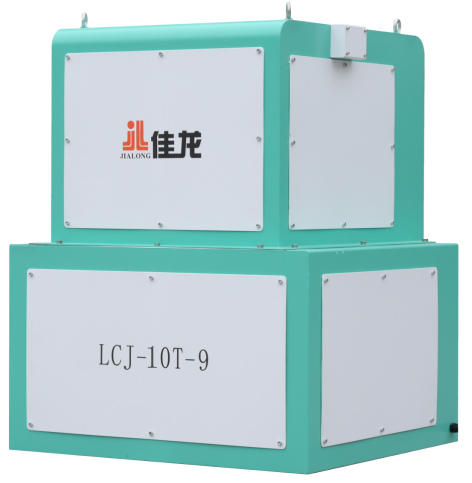

The Beans Mixing Machine, a highly efficient Food Blending Machine, is specifically engineered for accurate flow measurement of a variety of granular materials. This Food Blending Machine is designed to handle granular materials with a flow rate requirement of up to 10 tons per hour, making it ideal for processing materials such as rice, millet, soybeans, mung beans, and other similar granular materials. The Food Blending Machine utilizes advanced flow measurement technology to ensure precise handling of each batch of granular materials, improving efficiency, reducing waste, and ensuring consistent blending performance.

Email More

Ton bag packing machine for 500-1000kg Auto released of the bags Auto lifting for the pallet

Email More

This production line is in accordance with the conventional bagging process configuration, the entire production process a high degree of automation, in line with China GMP health standards

Email More

The vertical form fill sealing machine in accordance with the conventional bagging process configuration, the entire production process a high degree of automation, in line with China GMP health standards;

Email More

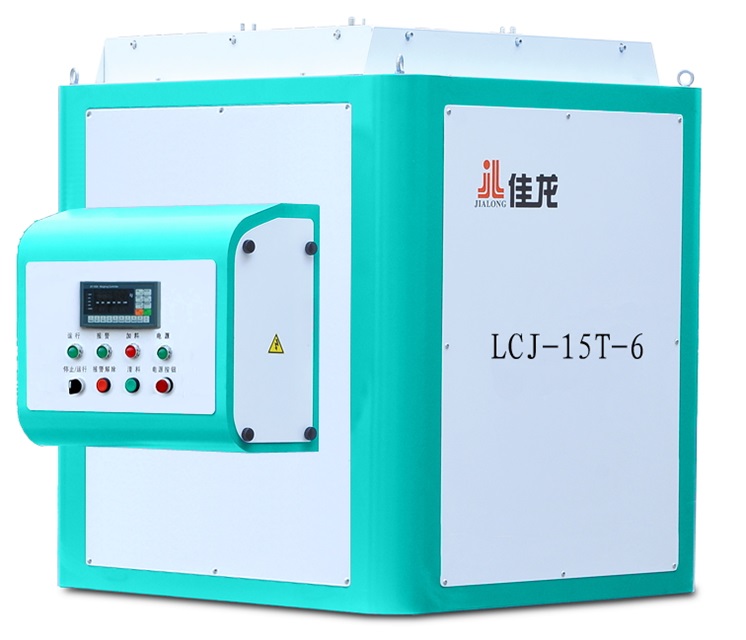

The rice mixing machine and grains blending machine play a crucial role in modern grain processing, chemical production, and port-based material handling. With advanced automation and precision flow control, the rice mixing machine ensures efficient blending of rice and similar granular products, delivering accuracy across continuous operations. Engineered for diverse blending tasks, the grains blending machine is suitable for mixing various grain types under dynamic flow conditions. Its integration into production lines allows real-time monitoring and minimizes material loss. Whether in agricultural applications or bulk processing, both the rice mixing machine and the grains blending machine offer high-performance solutions that optimize blending efficiency and streamline operations across multiple industries.

Email More

The rice blending machine and rice mixer play a vital role in sectors such as grain handling, chemical processing, and automated logistics, where stable operation and controlled material flow are essential. Engineered for precision, the rice blending machine delivers consistent results in the handling and proportioning of rice and similar grains. Meanwhile, the rice mixer provides enhanced adaptability for combining different bulk materials within intelligent production systems. These machines contribute to streamlined workflows, minimized interruptions, and reliable output quality across a wide range of industrial environments.

Email More

The filling weighing scale and flow scale for rice are essential systems in industries such as grain processing, chemical manufacturing, and grain storage. They are designed for efficient material handling and accurate volume measurement, particularly in high-capacity rice processing operations. The flow scale for rice incorporates a fully sealed, streamlined body paired with a dust-resistant electrical control unit, ensuring smooth, secure, and hygienic operation. The filling weighing scale, on the other hand, excels in continuous-duty environments, providing stable measurement accuracy and precise control over material flow, even under demanding conditions. Both systems are engineered to optimize operational efficiency, minimize downtime, and enhance overall productivity in various industrial applications.

Email More

The paddy weighing scale and paddy flow scale are critical instruments for precise material handling in sectors like grain processing, chemical manufacturing, and storage operations. The paddy flow scale is engineered with a fully sealed design, incorporating a streamlined main unit and a dust-resistant electric control panel, which ensures a clean, efficient working environment while minimizing contamination. The paddy weighing scale provides highly accurate measurements for large volumes of paddy, optimizing weight control during bulk handling. Meanwhile, the paddy flow scale ensures seamless material flow, offering consistent performance even in high-demand industrial settings. Both systems are built to enhance operational efficiency, ensuring minimal downtime and maintenance, and can be easily integrated into existing production lines.

Email More

The grains flow scale and grains weighing scale are vital systems designed for efficient material handling in industries such as grain processing, chemical manufacturing, and storage facilities. The grains flow scale ensures high accuracy in measuring and accumulating granular materials, optimizing processes in high-capacity environments.

Email More

The inkjet coding machine is purpose-built for the demands of Industry 4.0, where automatic, real-time code assignment is essential for intelligent manufacturing. Compact and lightweight, this advanced inkjet printer is designed for seamless integration into smart factories and modern automated production lines. With high adaptability and compatibility, the online coding machine easily connects with upstream and downstream equipment, enabling continuous, precise printing without interrupting the production flow. Whether for product traceability, batch marking, or expiry date coding, this inkjet coding machine ensures stable, high-speed operation in various industrial environments. As a versatile inkjet printer, it supports real-time data transmission and remote control, making it the ideal solution for digitalized, scalable production systems. The online coding machine brings smarter coding to packaging lines, increasing efficiency while reducing manual input and errors.

Email More

The rice flow scale is designed for efficient volume accumulation in industries such as grain processing, chemical production, grain storage, and port operations. It features an advanced material level control system that automatically adjusts to the speed of the next process, ensuring smooth transitions and optimizing workflow in high-demand environments. In rice mills and processing plants, the rice flow scale plays a vital role in precisely measuring rice for packaging and distribution. The rice flow scale ensures accurate portioning, improving operational efficiency and supporting consistent, high-quality output across the production line.

Email More