Precision Grain Blending System – 15 Tons Per Hour

Engineered for Medium-Scale Operations

For grain processing facilities that require a perfect balance of high-precision blending and efficient throughput, our 15 T/H Grains & Rice Blending Machine offers an ideal solution. This system is specifically engineered to deliver exceptionally uniform batches for medium-scale operations where blend quality and recipe accuracy are paramount.

It empowers you to create premium, value-added grain products with unparalleled consistency, making it a cornerstone for growth.

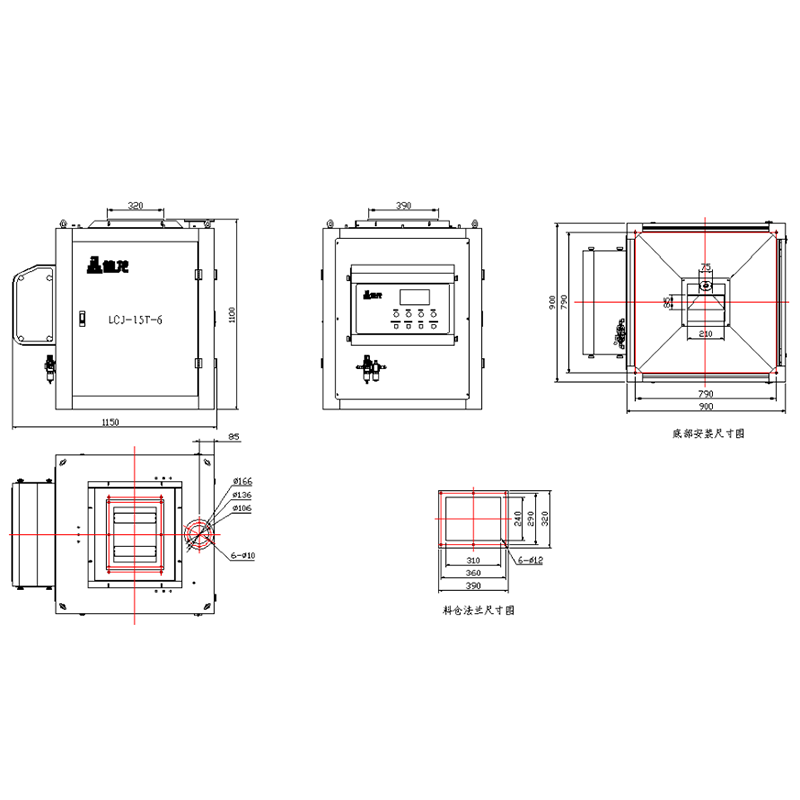

Model: LCJ-15T-6

Capacity: 15 Tons/Hour

Accuracy: Static ≤0.1%, Dynamic ≤0.5%

Key Advantages

Optimized Mid-Scale Throughput

With a steady 15 T/H capacity, this machine perfectly matches the production needs of mid-sized mills, ensuring an efficient workflow without the high costs of an oversized system.

Superior Blending Accuracy

Utilizes high-precision load cells and a smart dosing gate to guarantee that each ingredient is weighed accurately, protecting the integrity of your valuable proprietary recipes.

Intelligent Process Control

Features a user-friendly controller with functions for quantitative output and alarm stops. A reserved interface allows seamless integration into a central plant control system.

Gentle & Clean by Design

The internal structure is designed for gentle handling to preserve grain quality and appearance. Its residue-free design ensures quick, clean operation with minimal cross-contamination.

Technical Specifications

Below are the detailed technical specifications for our robust 15 T/H Grain Blending Machine model.

| Parameter | Model: LCJ-15T-6 |

| Capacity (Flow Rate) | 0.2 - 15 Tons/Hour |

| Accuracy | ≤0.5% |

| Power Consumption | 0.3 KW |

| Installation Dimensions (L×W×H) | 910 mm × 1150 mm × 1060 mm |

Main Component Configuration

This machine is built with globally recognized components to ensure reliability and performance:

| Component | Brand / Supplier |

| Weighing Controller | Harbin/Zhiyuanda |

| Low-Voltage Electricals (Button, Contactor, etc.) | French/Schneider |

| Load Cell Sensor | America/Celtron |

| Power Switch | Taiwan/Meanwell |

| Gear Reducer | Taiwan/Ruiyong |

| Pneumatic Element | Taiwan/Airtac |

Ideal Application Scenarios

1

Branded Rice Blending

Perfect for mid-sized rice mills to create unique, multi-variety rice packages for retail, enhancing brand value and market appeal.

2

Multi-Grain Food Production

Accurately mix ingredients for products like breakfast cereals, multi-grain flours, and health food mixes, ensuring consistent quality.

3

Precise Seed Mixing

Ideal for seed companies needing to produce uniform, precise mixtures of different seed varieties for agricultural use.

4

Custom Blend Formulations

Excellent for specialty grain suppliers who need to craft custom-ordered blends for wholesale or foodservice clients with specific requirements.

In-Depth Details

Operational Principle

The LCJ-15T-6 operates on a dynamic weighing principle. Material is fed from a supply silo into the machine's internal weighing hopper. As the material discharges, the controller continuously calculates the weight loss rate. It compares this live data against the target flow rate set by the operator and instantly signals the gear reducer to adjust the discharge gate opening. This closed-loop feedback mechanism guarantees a stable, consistent, and exceptionally precise flow of material, essential for modern production quality.

Our Commitment to Quality & Efficiency

We build our equipment for durability and peak performance. This blending machine features a robust, residue-minimizing internal structure that protects product purity and allows for rapid cleaning between batches. Our commitment to efficiency is demonstrated by the low 0.3 kW power consumption. By integrating globally-sourced, high-quality components, we deliver a dependable system that is meticulously tested and calibrated before shipment.

Comprehensive Customer & Technical Support

Expert Consultation: Our team can help analyze your process, materials, and facility layout to configure a system that maximizes your efficiency.

Full-Service Assistance: We offer robust after-sales support, including detailed manuals and direct remote access to our engineers for setup, operation, and troubleshooting.

Lifetime Service Guarantee: We provide lifetime technical support, ensuring you have expert help for any questions throughout the machine's entire operational life.

Frequently Asked Questions (FAQ)

Q1: Why choose this continuous flow machine instead of a traditional batch mixer?

A: A batch mixer processes a single, fixed volume at a time, creating bottlenecks in a continuous line. This continuous flow machine is built for uninterrupted production. It doses material at a constant, precise rate, making it far more efficient for consistent, high-volume industrial processing.

Q2: How can I create a recipe that combines three different types of grain?

A: To create a sophisticated blend, you would use multiple machines working in unison. For a three-grain recipe, you would set up three LCJ-15T-6 units. Each one is assigned a specific grain and set to the desired flow rate. They all discharge onto a common conveyor, creating a perfectly homogenous final product on the fly.

Q3: How does the triple-sensor configuration improve performance?

A: Our multi-sensor weighing system offers superior stability and faster signal response compared to basic designs. This technology filters out plant vibrations and gives the controller cleaner data, leading to faster, more precise adjustments of the flow rate and ultimate accuracy in your blend.