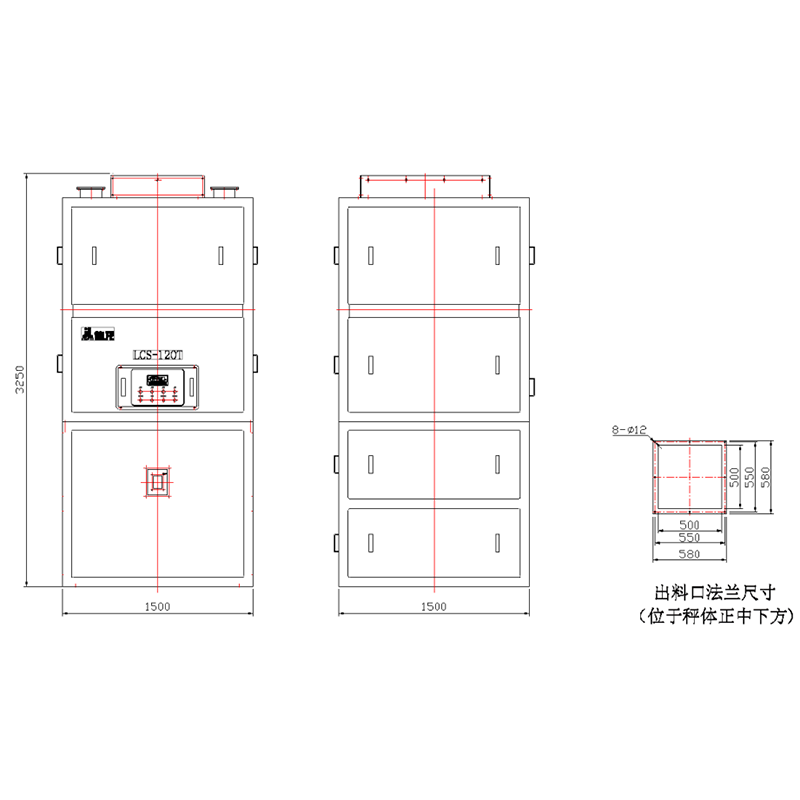

LCS-120T High-Capacity Weighing Flow Scale – 120 Tons/Hour

The LCS-120T: Your Industrial Weighing Workhorse

For large-scale grain processing facilities where high throughput and unwavering reliability are non-negotiable, the LCS-120T Weighing Flow Scale stands as the industry workhorse. Engineered to handle a formidable 120 tons per hour, this system is the robust powerhouse designed to be the backbone of your production line.

It provides the perfect combination of speed and precision, making it the optimal choice for large rice mills, grain terminals, and food processing plants that need to accurately measure and control massive quantities of bulk materials, safeguarding profits around the clock.

Model: LCS-120T

Capacity: 120 Tons/Hour

Core Technology: High-Speed Cumulative Weighing

Key Advantages

Industrial-Grade Throughput

A capacity of 120 TPH flawlessly matches the speed of high-capacity elevators and conveyors, ensuring a continuous, unimpeded flow of material through your facility.

Sustained Accuracy Under Load

At high volumes, our advanced control algorithm and high-sensitivity load cells maintain an exceptional accuracy of ±0.2% to protect your bottom line 24/7.

Built for Relentless Operation

Designed for demanding plant environments, this scale features a heavy-duty, dust-proof enclosed frame and wear-resistant contact parts to guarantee longevity.

Seamless Smart Factory Integration

Equipped with RS485/232 ports, the scale integrates effortlessly into your central PLC or SCADA systems for real-time monitoring, logging, and analysis.

Technical Specifications

| Parameter | Specification |

| Rated Throughput | 120 Tons/Hour (120 TPH) |

| Dynamic Accuracy | ≤ ±0.2% |

| Power Requirement | AC 220V, 50Hz, 70W |

| Air Supply | 0.4~0.6 MPa, 1 m³/h |

| Control Interface | Industrial PLC with Color Touchscreen |

| Data Connectivity | RS485 / RS232 Port |

Main Component Configuration

To guarantee robust performance and long-term reliability, the LCS-120T is assembled using carefully selected components from globally recognized brands.

| Component | Brand / Supplier |

| Weighing Controller | China/Zhiyuanda |

| Power Switch | Taiwan/Meanwell |

| Low-Voltage Electricals (Button, Knob) | France/Schneider |

| Load Cell | China/ZEMIC |

| Pneumatic Elements (Cylinder, Solenoid Valve) | Taiwan/Airtac |

Ideal Application Scenarios

1

Large Rice Mills

For precise measurement of raw paddy intake and finished rice outtake for bulk dispatch and yield calculation.

2

Grain Silo Terminals

Critical for high-speed, certified-weight loading and unloading of trucks, trains, and barges in busy logistics hubs.

3

Bulk Food Ingredient Plants

Accurately measures the flow of corn, wheat, or soybeans into large-batch mixing or continuous processing systems.

4

Ethanol & Biofuel Production

Manage the high-volume intake of feedstock (e.g., corn, grains) required for continuous and efficient biofuel production.

In-Depth Details

Working Principle

The system employs a high-speed, continuous batching method. Material is fed from your conveyor into the scale's upper buffer bin to ensure a steady supply. This material then fills the weighing hopper below it. Once the weigh hopper reaches its target weight, the inlet gate closes instantly. The controller records the precise weight and adds it to the running total. Finally, the bottom discharge gate opens, releasing the batch as the cycle immediately begins again, providing a precise, cumulative total without pausing your main material flow.

Our Commitment to Quality Engineering

Engineered for unwavering reliability, the LCS-120T is purpose-built for harsh industrial environments. Its robust, fully enclosed, and dust-proof design protects sensitive internal electronics and mechanisms. The main body and key contact components are crafted from wear-resistant materials to ensure a long operational lifespan, prevent contamination, and deliver a strong return on investment. Every unit undergoes rigorous factory testing and calibration to guarantee performance and accuracy from day one.

Frequently Asked Questions (FAQ)

Q1: How does this 120 TPH scale fit into a large rice mill's operations?

A: It's extremely versatile. It can be used at the primary intake point to weigh incoming raw paddy, between processing stages to measure yield, or at the final dispatch point to weigh bulk finished rice being loaded onto trucks or trains. It provides critical data for your entire process.

Q2: Can the scale truly maintain its ±0.2% accuracy at such high speeds?

A: Absolutely. The system is designed for it. The combination of rapid-response pneumatic gates, high-frequency data sampling from the load cells, and an intelligent controller algorithm ensures that each batch is weighed precisely, even in a continuous, high-velocity flow. This is crucial for accurate inventory and financial records.

Q3: Is the control system difficult for our operators to use?

A: Not at all. The scale is controlled via an intuitive color touchscreen interface. Operators can easily start/stop the process, view real-time data (like current flow rate and totals), calibrate the system, and set parameters. The display is clear and user-friendly, minimizing training time.