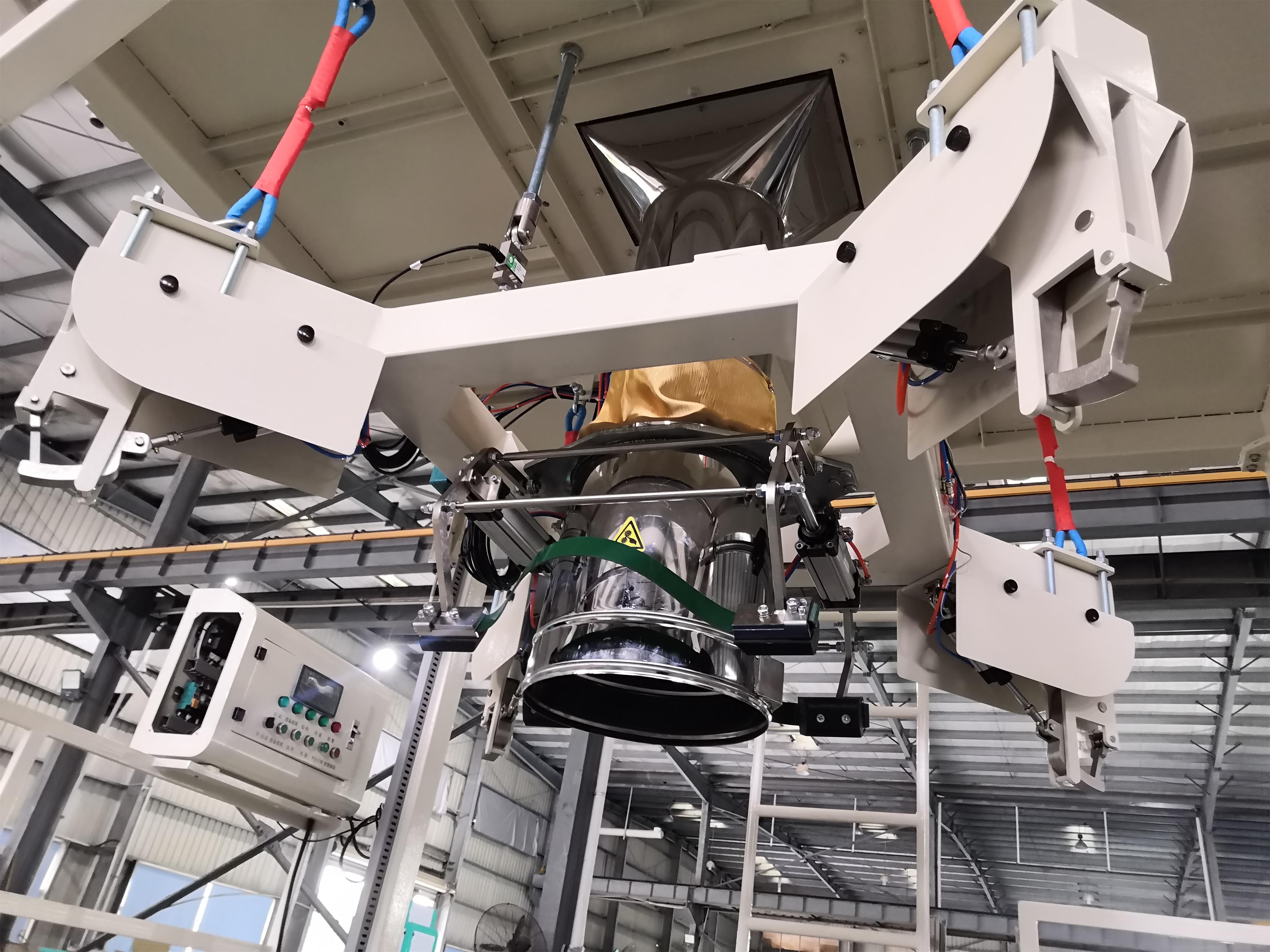

Model LCS-60T-CQ1: Automated Ton Bag Filling Machine for Granular Products

LCS-60T-CQ1 High-Efficiency Jumbo Bag Packer

This robust packing station is built to handle the demanding task of weighing and filling jumbo bags, or FIBCs, with capacities ranging from 500 to 1000 kg.

Utilizing premium international components, this system enhances the packaging workflow for granular substances, significantly decreases manual labor, and offers an optimal method for preparing goods for large-scale storage and logistics.

Model: LCS-60T-CQ1

Weighing Capacity: 500 - 1000 kg

Packing Speed: 20 - 30 bags/hour

Key Features & Advantages

Substantial Load Capacity

Engineered to precisely load large-format ton bags (FIBCs) with a maximum material weight of 1000 kg.

Superior Filling Accuracy

Delivers exceptional precision with an accuracy grade of X(0.2), thanks to its high-quality Celtron (USA) load cell and advanced control unit.

Enhanced Automation and Safety

Incorporates a rapid gravity feed mechanism and an automated bag loop disengagement system to boost safety and cut down on manpower.

Built for Durability

The machine's critical systems rely on globally recognized components from Schneider, Omron, and Airtac, ensuring long-lasting performance.

Machine Parameters

| Model | LCS-60T-CQ1 |

| Weighing Range | 500 - 1000 kg |

| Packing Speed | 20 - 30 bags/hour |

| Accuracy Grade | X(0.2) |

| Power Consumption | AC 380V 50Hz 2.8KW (Customizable) |

| Air Consumption | 0.4 - 0.6 MPa, ~1 m³/h |

| Installation Height | Approx. 3800 mm |

Core Component Breakdown

| Name | Brand |

|---|---|

| Weighing Controller | General Measure (Canada) |

| Load Cell | Celtron (USA) |

| Switches (Power, Limit) | Omron (Japan) |

| Breakers, Relays, Buttons | Schneider (France) |

| Pneumatic System (Cylinder, Solenoid Valve) | Airtac (Taiwan) |

Versatile Industry Applications

1

Grain and Seed Industry

Ideal for packaging grains like rice, corn, and soybeans, as well as various seeds, directly from storage silos into ton bags for shipment.

2

Chemicals and Manufacturing

Effectively handles the bagging of materials such as plastic resins, fertilizers, industrial salt, and other non-corrosive powders.

3

Construction and Mining Sectors

An excellent choice for efficiently packaging sand, aggregates, cement, and various other mineral-based construction materials.

4

Food Ingredient Processing

Specialized for bagging bulk food-grade ingredients, including sugar, salt, starches, and similar granular products for business-to-business supply.

Further Product Details

Focus on Quality and Operator Safety

Our design philosophy prioritizes both operational efficiency and user safety. The LCS-60T-CQ1 incorporates operator-centric features, such as the automatic bag release, to reduce physical effort. Additionally, an optional dust collection port can be integrated to maintain a clean, safe, and healthier workspace for your personnel.

Common Inquiries (FAQ)

1. Which FIBC (jumbo bag) formats are compatible with this machine?

Our system is engineered for standard four-loop FIBCs. We also offer customization for the filling spout to accommodate the unique inlet size of your bags.

2. What measures are in place for dust management during filling?

The machine creates a tight seal at the filling nozzle to minimize dust escape. It also comes equipped with a dedicated port for connecting to your facility’s dust collection system, ensuring a low-particle environment.

3. What is needed for the machine's installation?

A flat, sturdy concrete foundation is necessary to support the machine's weight plus a fully loaded 1000 kg bag. A vertical clearance of approximately 3.8 meters is required for proper setup.

4. Is this equipment suitable for handling fine powders?

This model utilizes gravity feeding, which is optimal for materials with good flow properties. For finer or less-flowable powders, we provide alternative solutions equipped with screw feeders. Contact our team to find the perfect match for your product.