Continuous Grains Flow Scale (60 T/H) – Optimizing Production Process Management

The Ideal Solution for In-Plant Process Control

For medium-scale grain and feed mills, precise control over material flow is key to optimizing costs and efficiency. Our LCS-60T Continuous Flow Scale is the perfect process management tool, designed for stable, reliable in-line measurement rather than extreme-speed bulk loading.

It transforms your production flow into precise digital data, allowing you to accurately monitor raw material intake, in-process transfers, and final product yield, enabling data-driven management and process improvement.

Model: LCS-60T Flow Scale

Capacity: 60 Tons/Hour

Best For: Process Control & Yield Monitoring

Key Advantages

Precise Process Data

Delivers a high cumulative accuracy of ≤ ±0.2%, providing reliable data for yield calculation, process loss analysis, and cost accounting.

Reliable Continuous Performance

Engineered for 24/7 factory operations. The robust, dust-proof construction ensures long-term stability as a trusted part of your automated production line with minimal maintenance.

Flexible Integration

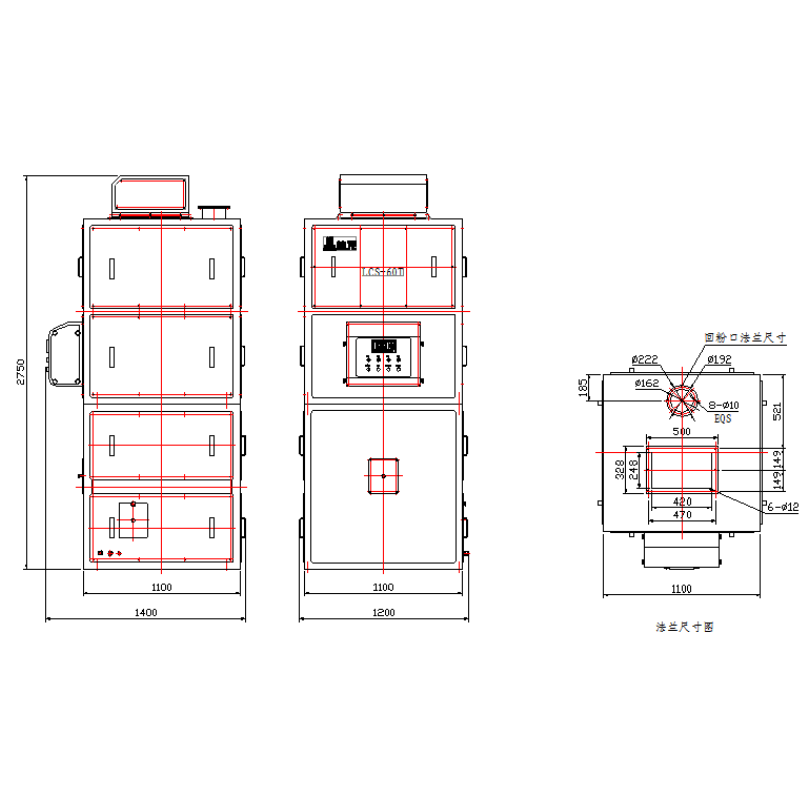

The balanced capacity and compact design allow for easy installation at key nodes in your production line, such as raw material intake, post-cleaning, or pre-storage.

Smart Data Management

The controller displays real-time flow rate and accumulated totals and can be easily connected to your plant's PLC or SCADA system via RS485 for centralized data logging and remote monitoring.

Technical Specifications

| Parameter | Model: LCS-60T Flow Scale |

| Designed Throughput | 60 Tons/Hour |

| Applicable Materials | Wheat, Corn, Soybeans, Paddy, Feed Pellets |

| Cumulative Accuracy | ≤ ±0.2% (Class 0.2) |

| Core Function | Continuous Dynamic Weighing, Auto-totalizing |

| Data Display | Instant Flow Rate (t/h), Accumulated Weight (kg/t) |

| Communication Port | RS485/RS232 (Modbus Protocol) |

| Ideal Environment | Grain Processing Mills, Feed Plants, Mid-Sized Storage Facilities |

In-Plant Application Scenarios

1

Raw Material Intake

Accurately measure the total weight of incoming grain from trucks for precise inventory receiving and supplier payment.

2

In-Process Monitoring

Install between cleaning, milling, or mixing stages to monitor material flow, ensuring process stability and tracking efficiency losses.

3

Yield & Output Totalling

Position before the finished product silo to get an accurate total weight of your daily or shift-based production output for precise yield records.

4

Internal Silo Transfer

When moving grain between internal storage silos, use the scale to accurately measure the transferred amount, keeping your stock records precise.

In-Depth Details

Operational Principle

The LCS-60T operates through a continuous cycle of high-speed batch weighing. Grain flows from an upper buffer into the main weighing hopper. When the weight reaches a set point, the inlet gate closes, the precise weight is recorded, and the discharge gate opens to release the material. This process repeats without interrupting the overall material flow. The intelligent controller automatically sums the weight of each batch to calculate a highly accurate cumulative total of the material that has passed through.

Our Commitment to Reliability in Mills and Plants

Engineered for reliability in demanding plant environments, the scale features a robust, fully enclosed design to protect sensitive components from dust. Key parts are made from wear-resistant materials to ensure a long service life with consistent accuracy. Each unit is rigorously factory-tested and calibrated to guarantee it performs flawlessly as a key data collection point in your process.

Frequently Asked Questions (FAQ)

Q1: What is the main purpose of this scale? Is it a packaging or bagging scale?

A: This is not a bagging scale. It is a 'flow scale' or 'totalizing weigher' designed to measure the total amount (tonnage) of bulk material passing through a point in your production line. Its primary purpose is process monitoring and inventory management, not filling individual bags to a specific weight.

Q2: Is the 60 T/H capacity suitable for very high-speed truck or ship loading?

A: The 60 T/H capacity is ideal for most in-plant processing lines and standard truck loading. For ultra-high-speed bulk logistics, such as loading large ships or railcars at a port terminal, we recommend considering our heavy-duty models (e.g., 150 T/H or higher) which are built for maximum throughput.

Q3: How do I integrate the weight data into our factory's control system?

A: The scale's controller includes a standard RS485 communication port that uses the common Modbus protocol. This allows your engineers to easily connect the scale to a central PLC or SCADA system to automate data collection for production reports and inventory management.