High-Precision Rice Quantitative Metering Flow Scale

Optimize Your Milled Rice Processing and Packaging Flow

In modern rice milling, every single grain counts. The ability to perform precise, continuous, and damage-free weighing of finished rice directly impacts your efficiency and profitability. Our High-Precision Rice Metering Flow Scale is specifically engineered for the delicate nature of milled rice.

It is more than just a scale; it's the intelligent core of your quality control and cost management. Designed for seamless integration, it automates flow monitoring and quantitative dosing from post-polishing to pre-packaging, ensuring every bag meets the highest standards of quality and weight accuracy.

Application: Finished Milled Rice, Grains, Beans

Key Feature: Gentle Handling, Low Breakage Rate

Accuracy: Dynamic ≤ ±0.2%

Key Advantages

Unmatched Precision

Utilizes high-sensitivity load cells and advanced algorithms to achieve ±0.2% accuracy. This minimizes costly product giveaway and ensures consistent package weights, maximizing your revenue.

Gentle Handling, Low Breakage

The internal structure is specially optimized with smooth transitions and buffer mechanisms to minimize impact and friction on rice grains, effectively reducing breakage and preserving product integrity.

Food-Grade Sanitary Design

All product-contact parts are made of 304 food-grade stainless steel. The smooth, seamless construction prevents residue buildup and allows for easy cleaning, fully complying with HACCP standards.

Intelligent Automation

Equipped with a PLC controller, the scale can link with upstream (e.g., polishers) and downstream (e.g., packaging machines) equipment for a fully automated, unattended production flow.

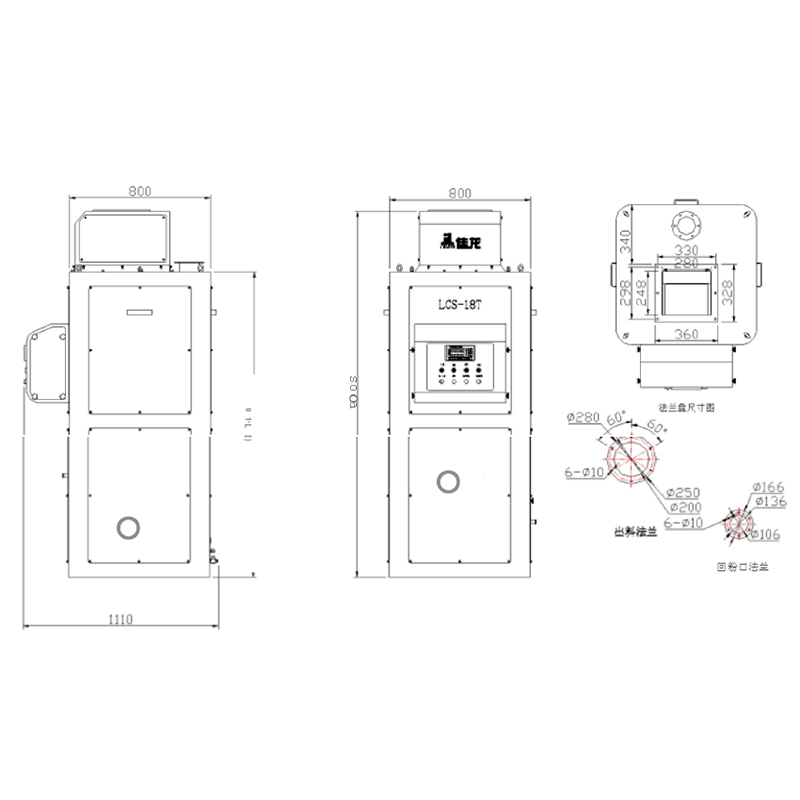

Technical Specifications

| Parameter | Specification |

| Model | LCS Series (Rice Application Specific) |

| Applicable Materials | Milled Rice, Millet, Legumes, other fine granular products |

| Weighing Range (Throughput) | 10 - 60 tons/hour (Customizable) |

| Measurement Accuracy | Static ≤ ±0.1%, Dynamic ≤ ±0.2% |

| Control System | PLC Intelligent Controller with Touch Screen HMI |

| Material of Construction | 304 Stainless Steel (Product contact parts) |

| Required Air Supply | 0.4-0.6 MPa |

| Power Supply | AC220V/380V, 50Hz (Customizable) |

| Communication Interface | Standard RS485/RS232 |

Typical Application Scenarios in Rice Milling

1

Post-Processing Control

Install after color sorters or polishers to accurately measure the flow of finished rice, enabling precise process control and yield calculation.

2

Pre-Packaging Dosing

Act as a quantitative feeder for vertical form-fill-seal (VFFS) machines or rotary packers, ensuring each final package has a highly accurate net weight.

3

Precision Blending

When creating mixed-rice products, use multiple scales to precisely control the flow rate and ratio of different rice varieties for a consistent final blend.

4

Inventory Management

Accurately measure and record the total weight of bulk finished rice transferred into or out of storage silos for precise inventory and production tracking.

In-Depth Details

Operational Principle

Rice flows from an inlet into the scale's upper buffer hopper, which then feeds the weighing hopper. When the rice in the weighing hopper reaches a preset weight, the inlet gate closes instantly and the controller records the precise weight. The discharge gate then opens, gently releasing the rice into the downstream process. This high-speed weighing and discharging cycle repeats continuously, while the intelligent controller sums each batch weight to provide a highly accurate, cumulative total.

Our Commitment to Food Safety and Reliability

Engineered for reliability in clean food processing environments, this rice scale features a fully sealed, dust-resistant design. All components in contact with rice are crafted from 304 food-grade stainless steel to ensure product safety, prevent contamination, and allow for thorough cleaning. Its low-power design reduces operational costs and environmental impact. Each unit is rigorously factory-tested and calibrated to guarantee it meets the highest standards of performance and accuracy upon delivery.

Frequently Asked Questions (FAQ)

Q1: How does this scale specifically prevent valuable milled rice from breaking?

A: Our design focuses on "gentle handling." The interior has smoothed pathways and a specially designed buffer system that slows the rice down before it enters the weighing hopper. The discharge gate also opens smoothly to prevent abrupt impacts, all of which work together to significantly reduce the rate of broken kernels compared to standard industrial scales.

Q2: Is this scale's material and design safe for direct contact with ready-to-eat rice?

A: Absolutely. All parts that touch the rice are made from 304 food-grade stainless steel, which is the industry standard for food safety. The design avoids corners and crevices where dust or particles could accumulate, making it easy to clean and compliant with food safety regulations like HACCP.

Q3: How does this scale connect to my automatic packaging machine for quantitative feeding?

A: The scale's PLC controller is designed for easy integration. It uses simple signal communication (I/O signals) or a more advanced RS485 interface to "talk" to your packaging machine. You can set a target weight (e.g., 25 kg) in the scale's controller, and it will precisely dose that amount and then signal the packager that the batch is ready, creating a seamless, automated workflow.