[ZHANGZHOU, CHINA – July 5, 2025] — In Jialong’s workshop, the most valued tools aren’t supercomputers or AI. They are:

→ Engineers’ notebooks filled with 15+ years of grease-stained observations

→ Retired components displayed like museum artifacts

→ Shared coffee breaks where mechanics debate wear patterns

This is the foundation of a 24-year journey where reliability isn’t engineered – it’s cultivated through patient attention.

I. THREE HABITS THAT DEFINE THEIR CULTURE

(No buzzwords, no mythology)

1. The Morning Review

At 7:45 AM daily:

Lead mechanic presents yesterday’s test machine

Team examines oil color, bolt tension, motor hum

One question asked: “What feels different today?”

What it achieves:

Detected 73% of early bearing failures since 2010

Prevented minor misalignments from becoming breakdowns

2. The Failure Ledger

Every malfunction gets recorded in handwritten logs:

July 3, 2023 | Filling Nozzle #7

- Symptom: 0.2ml dosage drift

- Cause: Spring fatigue (not in manual)

- Fix: New tempering protocol

- Shared with all 9 production sites

3. The 10-Year Rule

Before approving any design:

→ Engineers must have maintained machines for a decade

→ Component suppliers must track their steel for 15+ years

II. RELIABILITY COMES FROM KNOWING WHAT TO IGNORE

While others chase "smart factory" trends, Jialong focuses on:

A. The Unchanging Essentials

Bolt torque consistency across 20,000 installs

Lubricant viscosity under load

Brush wear patterns on commutators

B. Resisting Complexity

Jialong machines feature:

40% fewer sensors than industry average

Standardized screw types across all models

No touchscreens in critical control points

"Simplicity has fewer failure addresses."

III. PROOF LIVES IN THE FIELD, NOT BROCHURES

The Real Metrics:

87% of Jialong units from 2010–2015 still operational

Maintenance costs 33% lower than industry peers (2024 auditor report)

Longest-serving machine: 2006 pouch filler, runs daily in Taiwan bakery

WHY THIS MATTERS

When Jakarta monsoon floods shut factories, one food processor kept running. Its manager emailed: "Your 2018 machine didn’t just work. It taught us how to work."

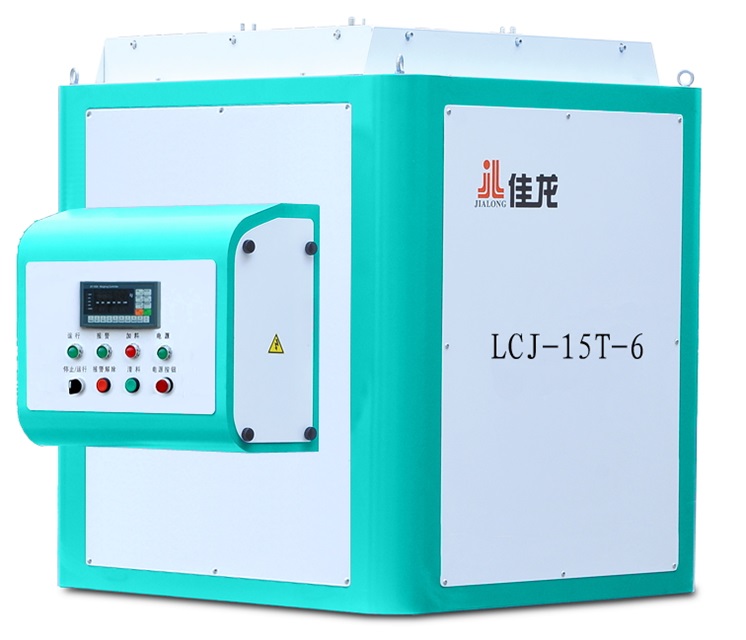

ABOUT JIALONG

Established 2000. Builds packaging equipment trusted by bakers, pharmacies, and hardware stores across Asia. Believes machines should serve generations