Exploring the engineering and science behind the market's most advanced preservation packaging, a cornerstone of modern food packaging equipment systems.

In the competitive world of consumer goods, packaging has evolved from a simple container into a sophisticated technological ecosystem. The most advanced packaging does more than just hold a product; a superior packaging solution actively preserves and communicates quality. At the zenith of this evolution lies vacuum shaping technology, a process integrating multiple engineering disciplines. The right brick shape packaging machine is central to this process, often as a key component in an automatic packing line.

Before preservation can occur, the process must begin with an unwavering foundation: accuracy. A quantitative filling machine is the critical first step in any quality-focused automatic packing line. An inconsistent fill weight leads to profit loss. A state-of-the-art quantitative filling machine achieves precision through advanced feeding mechanisms and high-sensitivity load cells. This is a core component of all modern food packaging equipment systems.

The precision of the quantitative filling machine is the cornerstone upon which the entire packaging process of an automatic packing line is built.

Removing oxygen is the most effective way to protect flavor, color, and nutritional value, a key function of a vertical form fill seal machine.

Once the precise amount of product is in the bag from the quantitative filling machine, the next pillar is engaged. A powerful vacuum pump rapidly evacuates the air, preventing oxidation in nuts and preserving the aroma of coffee. Often this function is seamlessly integrated into a vertical form fill seal machine, which forms, fills, and seals the bag in one continuous motion. The efficiency of a vertical form fill seal machine is what makes a high-speed automatic packing line possible.

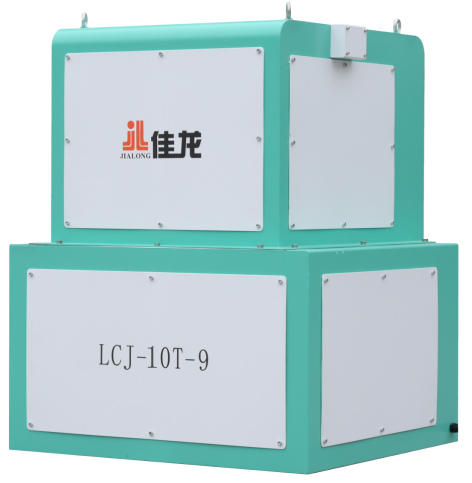

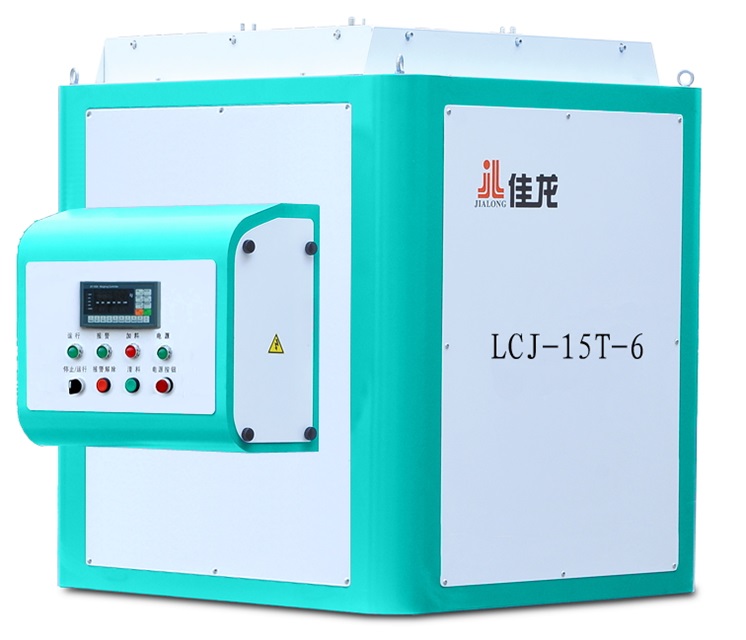

The final pillar transforms the package into a marketing asset. This is where a specialized brick shape packaging machine excels. Following the vacuum process, a precision-engineered mold shapes the package into a firm, geometric block. The result is a package with enhanced shelf appeal and improved logistical efficiency, a key feature of leading food packaging equipment systems. This step often follows the work of a vertical form fill seal machine.

See our Brick Shape Packaging Machine in action.

True excellence is achieved when these three pillars operate as a perfectly synchronized symphony. A modern automatic packing line orchestrates every step flawlessly. The precision of the quantitative filling machine, combined with the power of a brick shape packaging machine, creates the perfect final product. The integration of a flexible vertical form fill seal machine within this symphony is key. A modern automatic packing line is defined by this seamless integration.

Investing in comprehensive food packaging equipment systems is critical. A specialized brick shape packaging machine provides a competitive edge, while a reliable vertical form fill seal machine offers flexibility. Leading manufacturers provide a complete automatic packing line where every component is designed to work together. This creates an unparalleled level of efficiency.