The packaging machine of today is no longer just a mechanical workhorse; it is an intelligent, connected, and efficient system at the heart of modern manufacturing.

For decades, vacuum packaging has been a reliable ally in the fight against product degradation. However, modern market pressures for higher speeds and flexibility are catalyzing a profound technological evolution. The future of preserving goods lies in the intelligent execution delivered by a modern vacuum pack machine. These advancements are transforming what's possible for every type of system.

Let's explore the key technological pillars supporting this new generation, from the versatile double chamber vacuum packaging machine to fully integrated lines. Understanding this evolution is key to selecting the right vacuum pack machine for your business needs.

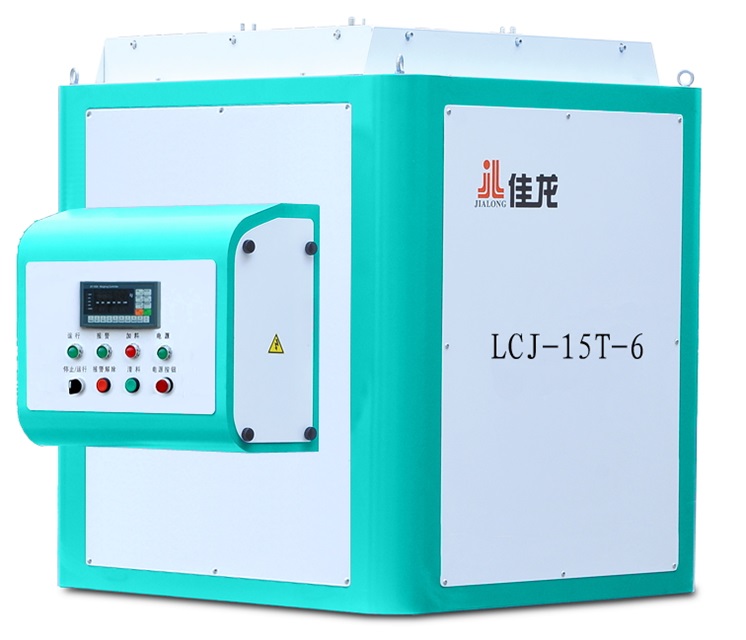

Today’s systems are sophisticated mechatronic platforms. PLC Control Systems act as the brain of any modern food vacuum sealer, orchestrating every action with precision. This leap defines modern automatic vacuum chamber machines. Clumsy pneumatic movements are being replaced by precise servo motors, resulting in faster cycle times. This is especially important in a high-throughput continuous vacuum packaging machine, where every second counts.

The integration of these technologies allows every modern vacuum pack machine to operate with unprecedented precision and speed, a far cry from its manual ancestors.

A truly advanced food vacuum sealer must adapt to the latest eco-friendly and high-barrier films. Even a sturdy double chamber vacuum packaging machine needs this flexibility.

A great machine is only as good as the materials it runs. The trend towards recyclable mono-material films means that the latest automatic vacuum chamber machines must be designed for flexibility. This applies to a large continuous vacuum packaging machine as well as a smaller tabletop model. Any modern food vacuum sealer must ensure a perfect, reliable seal on these new sustainable materials to be effective.

In a modern factory, Overall Equipment Effectiveness (OEE) is paramount. The latest systems are engineered to maximize uptime. Even a robust double chamber vacuum packaging machine benefits from features like modular design for quick parts replacement. The OEE focus defines next-generation systems, allowing a high-speed vacuum pack machine to operate at peak performance. This applies to all modern automatic vacuum chamber machines, making them profit centers. This efficiency-first mindset applies to every good food vacuum sealer.

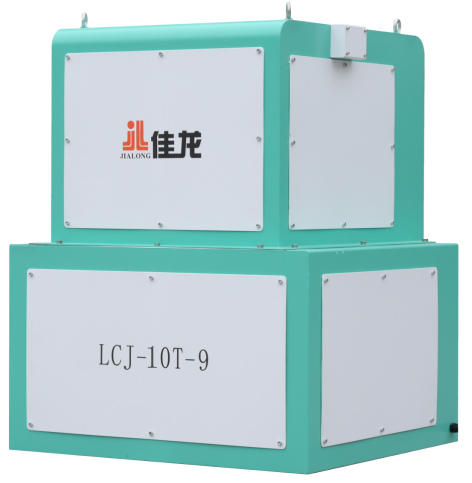

The development of packaging technology is linked to these advancements. Investing in a modern vacuum pack machine is an investment in a competitive future. Leading solutions range from the efficient double chamber vacuum packaging machine to a fully automated continuous vacuum packaging machine. A quality food vacuum sealer can redefine your brand. Choosing the right automatic vacuum chamber machines is a strategic decision for growth, ensuring you have the right vacuum pack machine. The flexibility of a double chamber vacuum packaging machine offers a great starting point for many businesses.