Vacuum packaging is a proven method, but the technology behind it is anything but static. Explore the cutting-edge innovations in automation, materials, and efficiency that are shaping tomorrow's industry standards.

For decades, vacuum packaging has been a reliable ally in the fight against product degradation. However, the pressures of the modern market—demands for higher speeds, flexibility, and lower operating costs—are catalyzing a profound technological evolution. The future of preserving goods lies in the intelligent and efficient execution delivered by modern vacuum packaging equipment.

Let's explore the key technological pillars supporting this new generation, from the foundational chamber vacuum sealer to fully integrated production lines. Understanding this evolution is key to selecting the right vacuum packaging equipment for your needs.

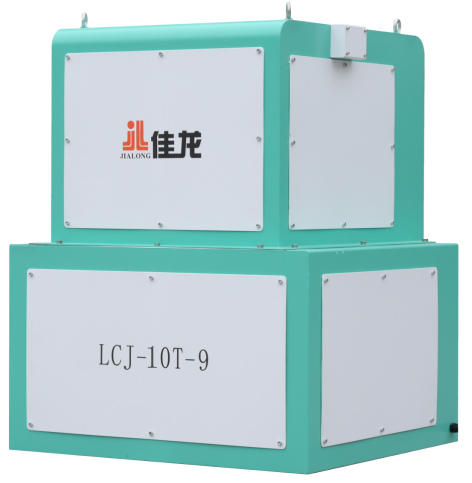

The story begins with the simple chamber vacuum sealer. An operator would place a product in a bag and initiate a manual cycle. This first-generation machine was revolutionary for its time, but it was slow and labor-intensive. Its primary function was simply to be an effective food packaging sealing machine. However, this foundational technology set the stage for every future industrial vacuum sealer and automated system. The principles established by this basic chamber vacuum sealer are still relevant today.

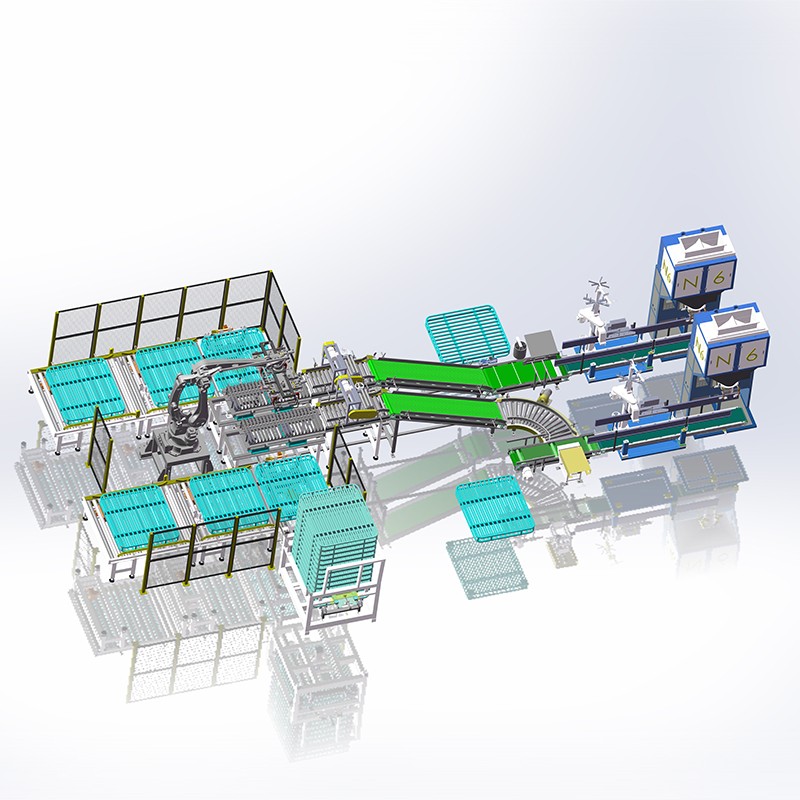

The first major leap was the introduction of automation. This ushered in the age of the true automatic packaging machine. By integrating conveyors and logic controllers, products could flow seamlessly through the vacuuming and sealing stations. This pivotal moment increased throughput exponentially. The era of the high-performance industrial vacuum sealer had arrived, offering a significant upgrade over any manual chamber vacuum sealer. This innovation cemented the role of the automatic packaging machine in large-scale production.

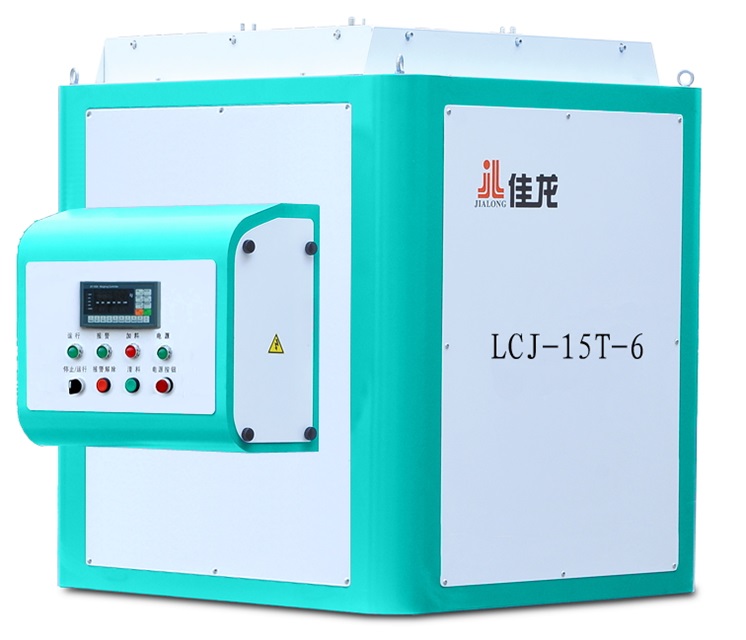

Today's systems are true mechatronic platforms, controlled by PLCs and servo motors. This intelligence defines the modern automatic packaging machine. At the same time, material science has advanced. To handle new sustainable and high-barrier films, the sealing component must be highly advanced. Therefore, any top-tier piece of vacuum packaging equipment must also be a superior food packaging sealing machine. A high-quality seal is non-negotiable, a function perfected far beyond the basic capabilities of an early chamber vacuum sealer. Every aspect of today's industrial vacuum sealer has been optimized for performance.

The development of vacuum packaging equipment is intrinsically linked to these advancements. The right food packaging sealing machine can enhance product safety. Investing in the right automatic packaging machine is investing in efficiency. Choosing the right industrial vacuum sealer means choosing reliability at scale. A state-of-the-art food packaging sealing machine ensures your brand's promise of quality is delivered. Even a basic chamber vacuum sealer plays a role in smaller operations, showcasing the technology's scalability.