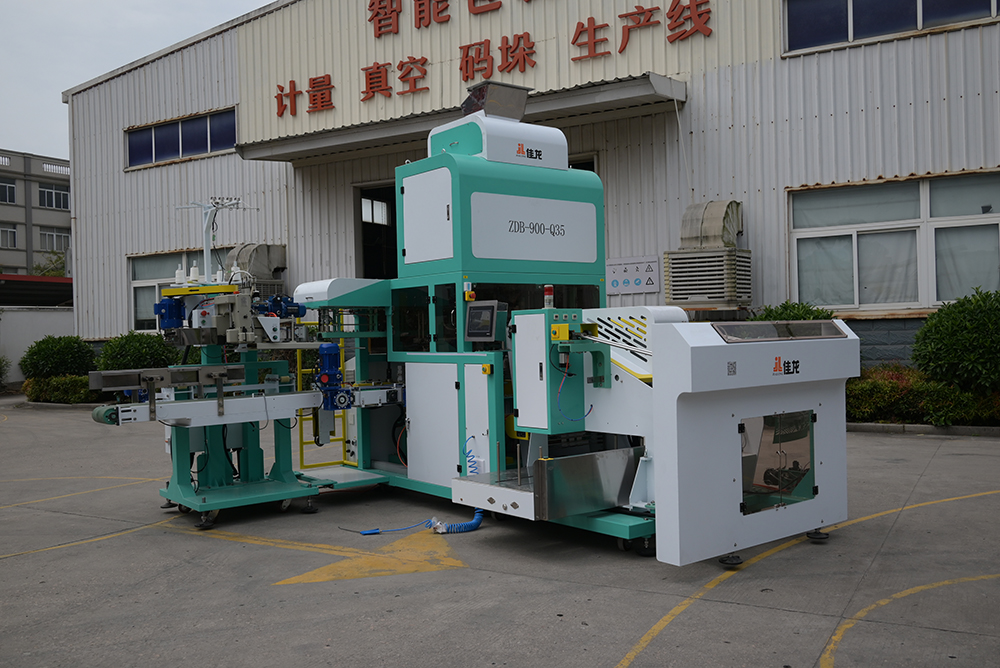

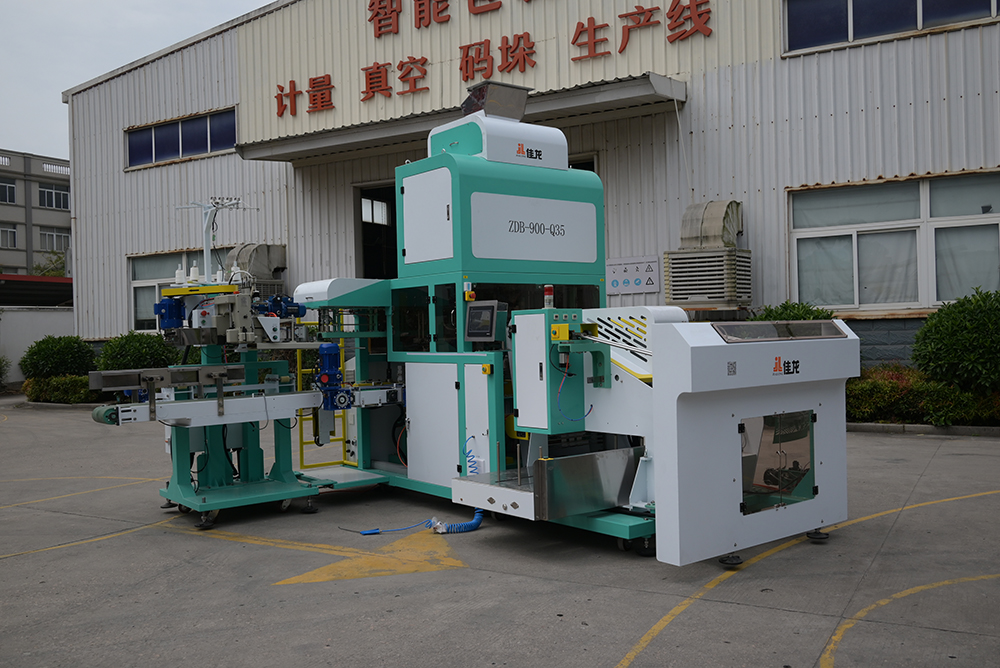

Jialong Unveils ZDB-900-Q35: The High-Speed Automatic Packaging Machine Engineered for Maximum Throughput

ZHANGZHOU, China – [July 28, 2025] – In a significant leap forward for industrial packaging solutions, Jialong Packaging today introduced the ZDB-900-Q35 Fully Automatic Packaging Machine, an automated bagging system engineered from the ground up to solve the most pressing challenges in modern manufacturing: speed, accuracy, and labor dependency. With a verified throughput of up to 900 bags per hour, this machine is set to become the new industry standard for businesses aiming to scale their operations efficiently.

The global manufacturing landscape is facing a perfect storm of rising labor costs, workforce scarcity, and intense consumer demand for consistently high-quality products. In this environment, an investment in a robust industrial packaging solution is no longer a luxury but a critical strategic move. The Jialong ZDB-900-Q35 is designed to be that strategic asset, offering a definitive solution for companies in the agricultural, food, chemical, and building materials sectors.

"Our clients' main pain points are production bottlenecks and the unreliability of manual labor," explains David Chen, Chief Engineer at Jialong Packaging. "We designed the ZDB-900-Q35 not just as a piece of equipment, but as a complete ecosystem for packaging efficiency. It's a 'set it and forget it' solution that lets business owners focus on growth instead of managing the production line."

How Does The Jialong ZDB-900-Q35 Automated Bagging System Work?

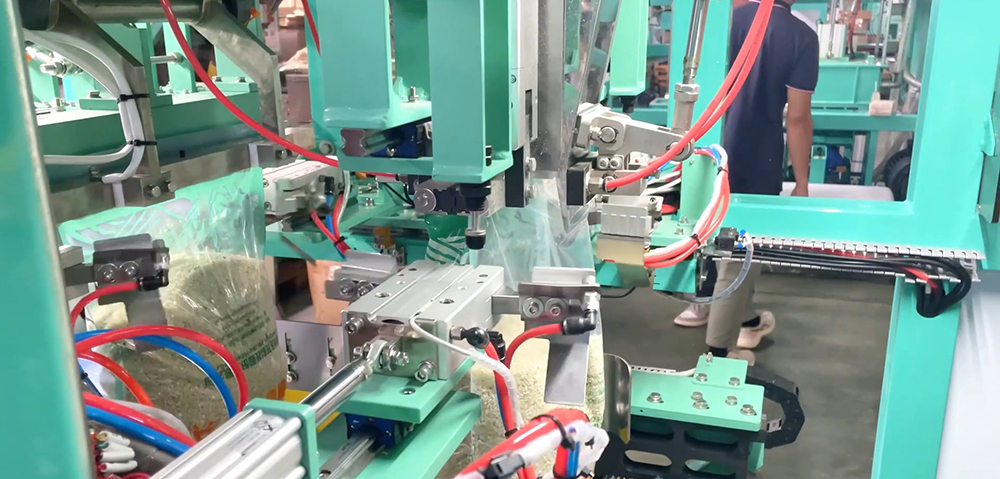

The ZDB-900-Q35's performance is rooted in a meticulously synchronized five-stage process, ensuring every cycle is as flawless as the last. This advanced workflow is what separates a true automatic packaging machine from its less reliable counterparts.

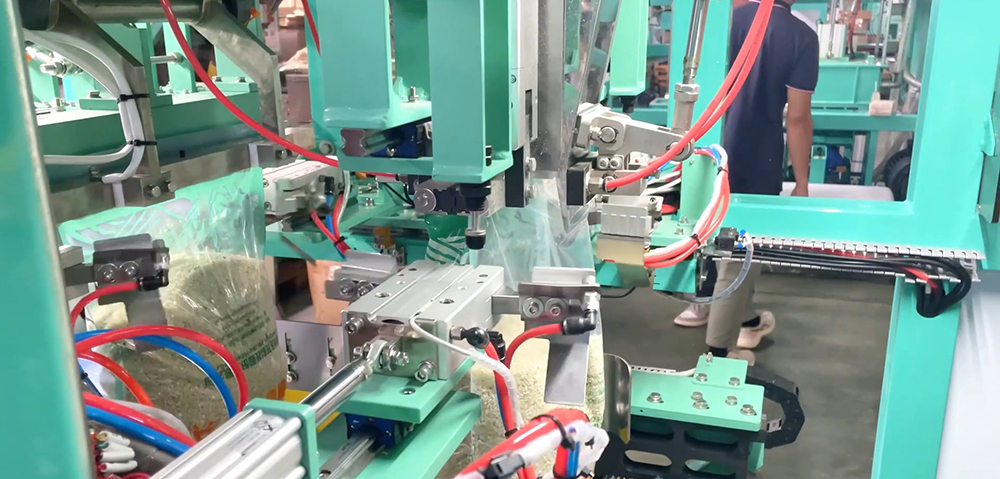

Automated Bag Magazine & Feeding: The process starts with a high-capacity horizontal bag magazine. An intelligent vacuum-powered robotic arm picks a single pre-made bag, utilizing sensors to prevent misfeeds and ensure a one-bag-at-a-time pickup.

Accurate Bag Opening & Placement: The bag is then transferred to an opening station where mechanical grippers and a jet of air ensure it is fully and correctly opened before being precisely positioned under the filling spout.

High-Precision Weighing & Filling: A multi-head or net-weighing system, integrated via a central PLC, measures the product (from 5kg to 25kg) with exceptional accuracy. This precision minimizes costly product giveaway and is a core feature of this advanced granule packing machine.

Vibratory Settling & Conveying: Post-filling, the bag is gently vibrated to settle the contents and remove excess air, creating a more compact and stable package for palletizing. It is then securely conveyed to the final station.

Robust Heat Sealing & Discharge: The final stage uses a continuous heat sealer to create a durable, airtight seal that protects product integrity. The finished, sealed bag is then discharged onto an output conveyor, ready for shipping.

What Problems Does This High-Speed Bagger Solve for Businesses?

Investing in industrial automation is about solving tangible business problems. The ZDB-900-Q35 directly addresses the most common and costly operational hurdles.

The Labor Problem: It drastically reduces dependency on manual labor, mitigating the impact of staff shortages and eliminating the human error and fatigue that lead to inconsistent output and workplace accidents.

The Throughput Problem: Capable of running 24/7 at 900 bags/hour, it smashes production ceilings, allowing businesses to accept larger orders and respond faster to market demand.

The Profitability Problem: By minimizing product waste through precise weighing, reducing labor costs, and maximizing uptime, this machine delivers a rapid and compelling return on investment (ROI). The ZDB-900-Q35 isn't a cost center; it's a profit center.

The Quality Control Problem: This automated system ensures every single bag is filled to the correct weight and sealed perfectly, enhancing product quality and protecting your brand's reputation for excellence.

Technical Specifications: A Closer Look at the ZDB-900-Q35

Below are the key technical specifications that make the Jialong ZDB-900-Q35 a premier choice in industrial packaging solutions:

Model: Jialong ZDB-900-Q35

Packaging Speed: Up to 900 bags/hour (material dependent)

Weighing Range: 5kg - 25kg

Bag Types: Pre-made open-mouth bags, including paper, PE, and woven bags

Control System: Siemens/Mitsubishi PLC with a color touchscreen HMI

Materials: Ideal for free-flowing granular products like rice, pet food, seeds, salt, plastic pellets, and chemical fertilizers.

Construction: Heavy-duty stainless steel contact parts (SS304) and a robust carbon steel frame for long-term durability.

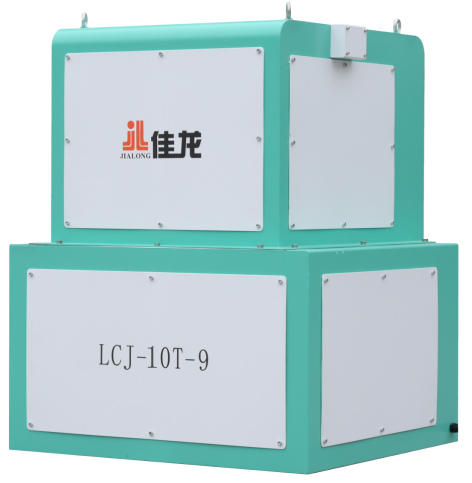

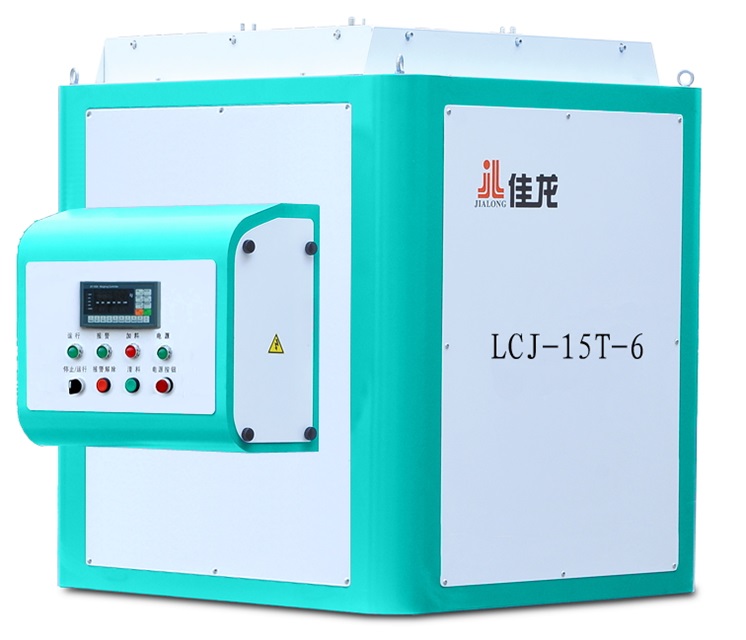

About Jialong Packaging: Your Partner in Automation

Jialong Packaging is a world-class manufacturer dedicated to engineering the future of industrial automation. We don’t just sell machines; we build partnerships. Our team works closely with clients to understand their unique production environments and deliver tailored solutions that drive real-world results. Our commitment to quality, innovation, and customer support makes us the trusted choice for businesses aiming to lead their industries.

To receive a detailed technical sheet for the ZDB-900-Q35 Automatic Packaging Machine or to schedule a consultation with an automation specialist, please contact us.

Contact Information:

Website: [www.easypackingmachine.com]

Sales Inquiry Email: [export@jialong.cn]

Direct Phone: [+86-13906062253]