The journey of the modern vacuum packing machine mirrors the history of manufacturing itself—a relentless progression from manual labor to intelligent, integrated systems.

The simple yet profound concept of removing air to preserve goods has fueled decades of remarkable engineering innovation. The equipment of today bears little resemblance to its early ancestors, having evolved from simple, standalone devices into highly sophisticated systems. This is especially true for any modern vacuum packaging machine for food, which now stands as a central pillar in modern food processing chains.

This technological journey can be charted through several key developmental milestones, each leap forward bringing new levels of speed, efficiency, and capability to producers of goods from delicate foods to precision medical devices.

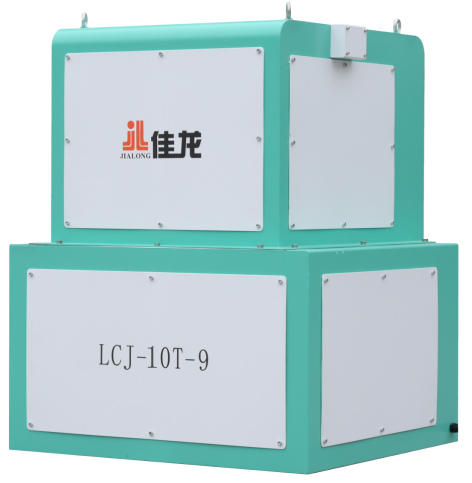

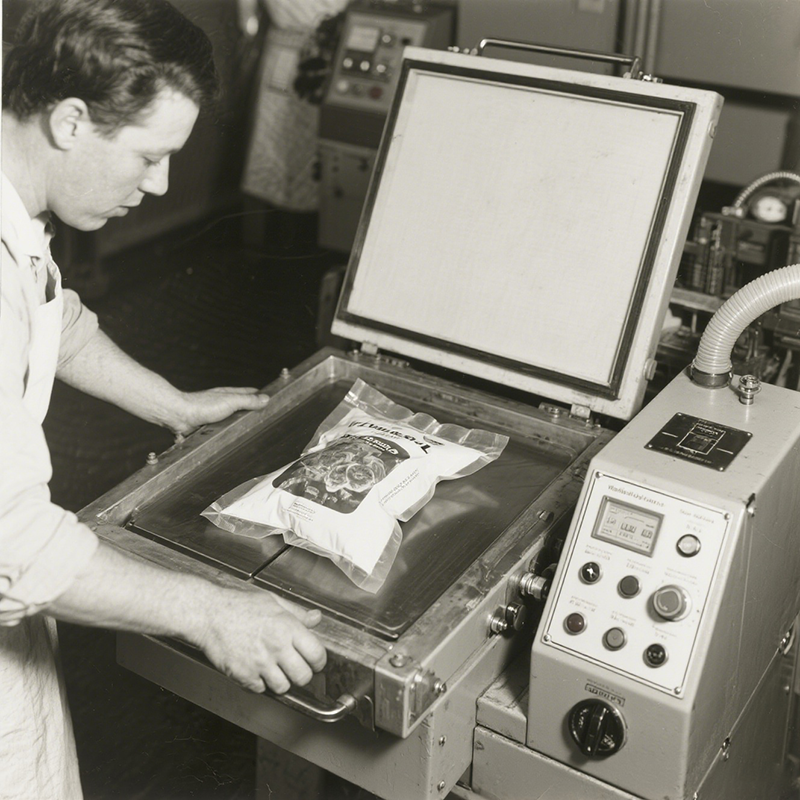

The story begins with the simple chamber sealer, the earliest form of a professional vacuum sealing machine. An operator would place a product in a bag, put it in the chamber, and initiate a manual cycle. This first-generation commercial vacuum packaging machine was revolutionary for its time, enabling small businesses like butcher shops and delis to extend the life of their products. Despite being slow and labor-intensive, the essential function of this early commercial vacuum packaging machine set the stage for all future innovations.

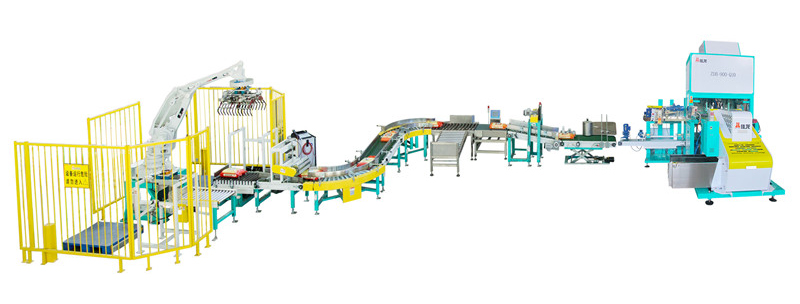

The first major leap came as demand for packaged goods soared, ushering in the age of the automatic vacuum packaging machine. By integrating conveyor belts and logic controllers, products could flow seamlessly through the vacuuming and sealing stations. This pivotal moment increased throughput exponentially, providing the consistency needed for large-scale food producers. The era of the true industrial vacuum packaging machine had arrived, changing the landscape of food production forever.

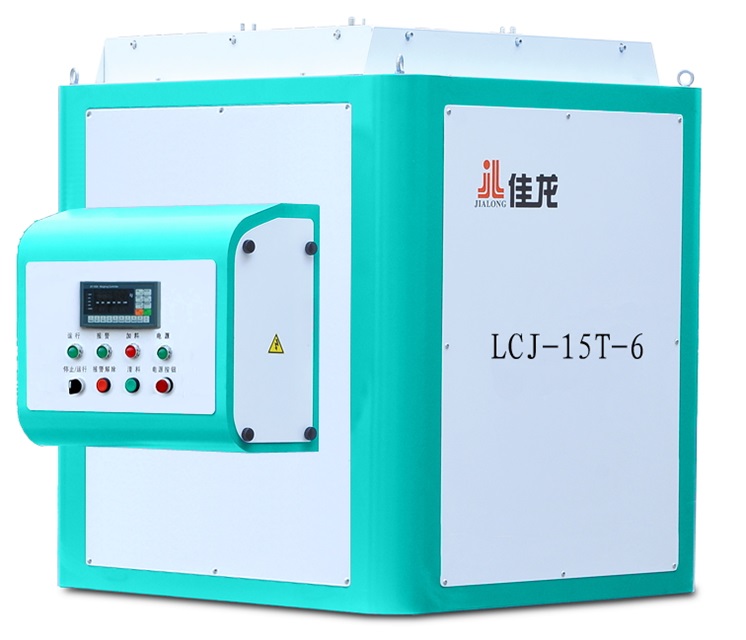

The current generation of equipment represents the fusion of robust mechanics with advanced electronics. These modern mechatronic systems are controlled by powerful PLCs and precise servo motors. Every movement is a carefully orchestrated action, boosting speed and allowing for features like automatic recipe changes and fault self-diagnosis. An advanced automatic vacuum packaging machine can now handle a wide variety of products with unparalleled gentleness. This level of sophistication defines the modern industrial vacuum packaging machine, making it smarter than ever before.

This journey from a user-operated commercial vacuum packaging machine to a fully integrated industrial vacuum packaging machine highlights a key trend: packaging is now an integral part of manufacturing. A modern vacuum packaging machine for food must be reliable, fast, and intelligent to meet today's demands. Each evolution of the vacuum sealing machine has been a direct response to the market's need for higher quality, proving its versatility beyond being just a commercial vacuum packaging machine.

The development of the automatic vacuum packaging machine is far from over. The future holds greater integration with factory-wide data systems and AI for predictive maintenance. As the premier vacuum packaging machine for food, it will continue to adapt to new sustainable materials. The capabilities of every modern vacuum sealing machine will continue to expand exponentially.