High-Speed, Twin-Head Semi-Automatic Packaging Line - Model DCS-25K-3C

DCS-25K-3C High-Throughput Packaging Line

An advanced packaging line designed to maximize the efficiency of your bagging operations. Featuring a state-of-the-art twin-head weighing system, it can achieve speeds of up to 900 bags per hour.

This complete system integrates the scale with an industrial sewing machine and conveyor, making it the ideal solution for packaging rice, seeds, pellets, and other granular materials.

Model: DCS-25K-3C

Peak Throughput: Up to 900 bags/hour

Weighing Range: 5 - 50 kg

Product Highlights

Extreme Packaging Speed

Twin weighing hoppers work in parallel to achieve continuous high-speed flow, reaching up to 900 bags per hour.

High-Precision Weighing

A three-stage feeding system ensures rapid filling while maintaining a superior accuracy grade of X(0.2).

Complete Integrated Line

This is a turnkey solution, including the packaging scale, industrial sewing machine, and lifting conveyor.

Compact & Reliable Design

An innovative single-cylinder mechanism results in a more compact structure, faster response, and lower failure rates.

Technical Specifications

| Model | DCS-25K-3C |

| Weighing Range | 5 - 50 kg |

| Packing Speed | 600 - 900 bags/hour (for 5-25kg); 300 - 400 bags/hour (for 25-50kg) |

| Accuracy Grade | X(0.2) |

| Power Consumption | 4N-AC 380V 50Hz 1.1KW (Customizable) |

| Air Consumption | 0.4 - 0.6 MPa, ~2 m³/h |

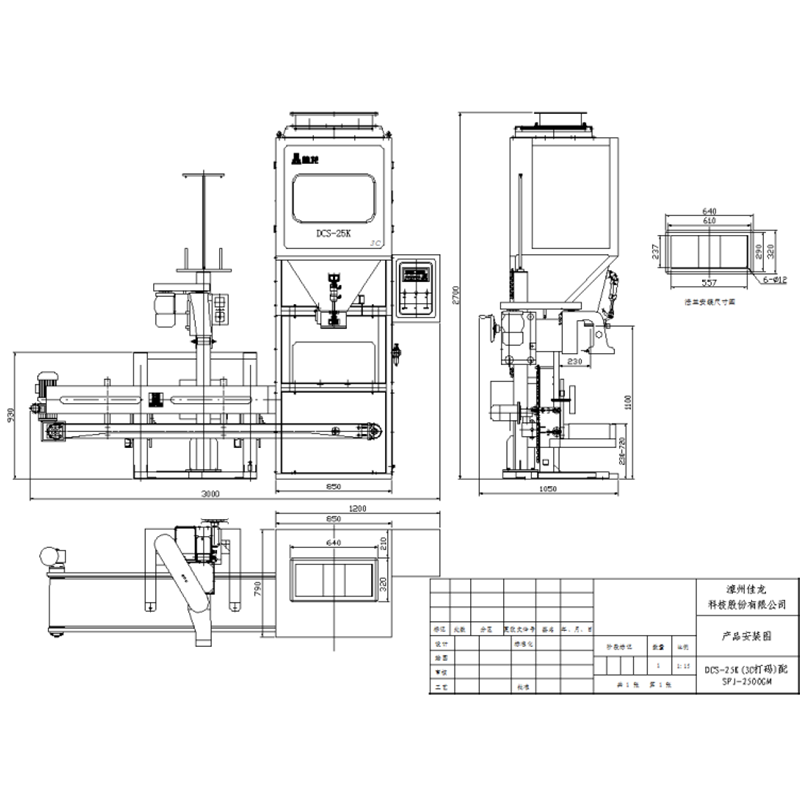

| Overall Dimensions (L×W×H) | Approx. 3000 × 1050 × 2700 mm |

Main Configuration

| Item | Brand |

|---|---|

| Weighing Controller | Zhiyuanda |

| Load Cell | Celtron (USA) |

| Switching Power Supply | Meanwell (Taiwan) |

| Buttons & Knobs | Schneider (France) |

| Pneumatic System (Cylinder, Solenoid Valve) | Airtac (Taiwan) |

Application Scenarios

1

Grain & Agricultural Sector

The ultimate solution for high-speed bagging of rice, wheat, beans, and all types of seeds for commercial markets.

2

Food & Ingredient Production

Ideal for accurately packaging granular sugar, salt, and other food commodities where speed is essential.

3

Animal Feed & Pet Food

Perfectly suited for the rapid, continuous bagging of animal feed pellets, specialty grains, and dry pet food.

4

Industrial Materials & Minerals

Excellent for bagging plastic pellets, wood pellets, specialty sands, and other free-flowing granular materials.

Detailed Information

Our Commitment to Quality Manufacturing

Premium Component Sourcing: We use electrical and pneumatic components directly from global leaders like Schneider and Airtac to ensure consistent performance.

Precision Calibration: Our technicians are experts in high-speed weighing. Each Celtron load cell is meticulously calibrated to guarantee accuracy across millions of cycles.

48-Hour High-Speed Stress Test: Every packaging line undergoes a 48-hour continuous run test at peak speed to verify its long-term stability and endurance under pressure.

Final System Certification: Before shipment, a senior engineer conducts a final quality assurance audit, signing off on all systems to ensure it is ready for immediate deployment.

Frequently Asked Questions (FAQ)

1. What does "semi-automatic" mean for this line?

An operator's main task is to place empty bags on the twin filling spouts. The machine then automatically clamps the bag, fills it to the target weight, and releases it to the conveyor for automated sewing.

2. Can a single operator achieve 900 bags/hour?

The machine's speed is adjustable. While it's capable of 900 bags/hour, this often requires a highly efficient workflow. A single operator can comfortably run the machine at a slightly lower, yet still very fast, pace.

3. How does it handle different bag weights like 25kg and 50kg?

The target weight is easily set in the controller. The machine is optimized for speed with smaller bags (e.g., 25kg) and runs at a still-fast but more moderate pace for heavier bags (e.g., 50kg) to ensure accuracy and stability.

4. Why is the double stainless steel hopper a key feature?

Stainless steel is essential for hygiene in food applications, prevents rust, and is easy to clean. The dual-hopper (twin-head) design is the core technology that allows the machine to weigh one batch while filling another, which is how it achieves its market-leading speed.