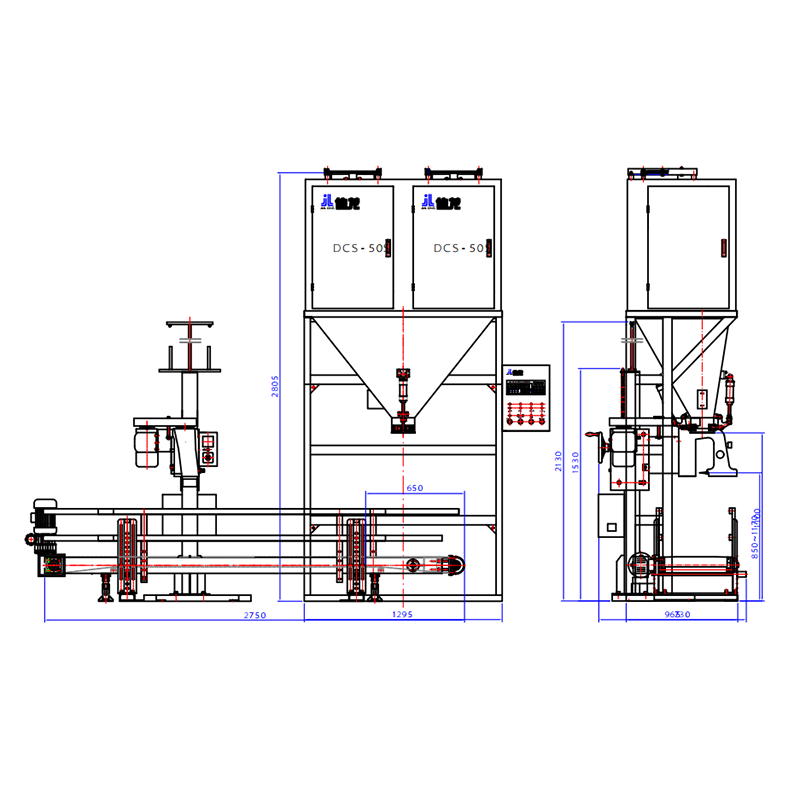

DCS-50S Semi-Automatic Granule Packing Machine

DCS-50S High-Speed Semi-Automatic Packing Scale

Engineered for precision and efficiency, this semi-automatic packing scale is your ideal solution for weighing and packaging a wide variety of granular materials.

It utilizes an intelligent weighing controller and high-quality pneumatic components to deliver stable performance and high throughput, making it perfect for the food, agriculture, and chemical industries.

Model: DCS-50S

Capacity: 500-600 bags/hour

Material: Contact parts are made of durable stainless steel

Core Highlights

High-Speed Throughput

Features a dual feeding and weighing system to maximize packing speed and greatly enhance production yield.

Precision Weighing

Equipped with high-accuracy ZEMIC load cells and an advanced controller for stable, precise weighing with automatic error correction.

Reliable Components

Built with globally recognized components, including Airtac pneumatics and Schneider electrical parts, for long-term stability.

User-Friendly Design

Offers simple, intuitive operation, fault auto-diagnosis, and an easy-to-clean design with stainless steel material contact parts.

Technical Specifications

| Model | DCS-50S |

| Weighing Extent | 20~50 kg per bag |

| Operation Speed | 500-600 bags/hour |

| Accuracy Grade | X(0.2) |

| Weighing Interval | 10 g |

| Power Requirement | 4N-AC 380V 50Hz |

| Power Consumption | 1 KW |

| Air Consumption | 0.4~0.6MPa, 1m³/h |

| Installation Height | 3100 mm |

Main Component Configuration

| No. | Component Name | Brand / Supplier |

| 1 | Weighing controller | Zhiyuanda |

| 2 | Switch | Taiwan/Meanwell |

| 3 | Button | French/Schneider |

| 4 | Load cell | ZEMIC |

| 5 | Pneumatic element | Taiwan/Airtac |

| 6 | Cylinder | Taiwan/Airtac |

| 7 | Solenoid valve | Taiwan/Airtac |

Versatile Application Scenarios

1

Grain Processing

Efficiently packing rice, wheat, corn, beans, and other staple grains. Perfect for a rice bag sealing machine application.

2

Agriculture & Seed Industry

Precise, quantitative packaging for all types of crop seeds, animal feed, and fertilizers.

3

Food Manufacturing

Ideal for weighing and bagging sugar, salt, nuts, and other granular food ingredients with hygiene and safety.

4

Chemical & Industrial

Dependable packaging for plastic pellets, resin particles, and other non-corrosive industrial granular materials.

In-Depth Product Details

Operational Principle and Workflow

The DCS-50S semi-automatic packing scale operates on a streamlined principle: an operator manually places an empty bag onto the filling spout and presses a switch. The machine then automatically clamps the bag, initiates the dual-stage feeding system for fast and precise weighing of the material, and fills the bag to the preset weight. Once complete, the bag is released, ready for the operator to move it to a sewing or sealing station. This combination of automation and manual control ensures both high efficiency and flexibility.

Quality Control and Manufacturing Process

Our dedication to excellence is evident in our manufacturing process. Every machine begins with a strict inspection of incoming raw materials, especially the stainless steel and key electronic/pneumatic components. During assembly, skilled technicians meticulously build each unit to precise engineering standards. Before shipment, every packing scale undergoes a rigorous quality assurance protocol, including continuous operational testing and accuracy calibration, to guarantee it delivers the reliable performance our customers expect.

Service and Support Commitment

Pre-Sales Consultation: Our team will help you analyze your needs to ensure the DCS-50S is the perfect fit for your specific granular materials and production goals.

After-Sales Support: We provide comprehensive installation guidance, operator training, and a full machine warranty. Lifelong technical assistance is always available.

Spare Parts Availability: We maintain a ready stock of all essential components like load cells, cylinders, and solenoid valves to minimize any potential downtime.

System Integration: The machine reserves an RS232/485 interface, making it easy to connect with upstream and downstream equipment like conveyors and bag sealers.

Frequently Asked Questions (FAQ)

Q1: What is the maintenance requirement for this machine?

A: Routine maintenance involves keeping the machine clean, especially the weighing hopper and sensors, and periodically checking the pneumatic system. A detailed guide is provided in the user manual.

Q2: Can the packing weight be easily adjusted?

A: Yes, the target weight can be quickly and easily changed via the user-friendly interface on the weighing controller, accommodating different production runs.

Q3: What type of bags can be used?

A: The machine is compatible with a wide range of open-mouth bags, including woven polypropylene (PP) bags, paper bags, and poly bags.