Elite Fully Automated Rice Bagging Line - Model ZDB-900-Q8

ZDB-900-Q8 High-Speed Automatic Rice Packer Line

A complete, end-to-end automated system for bagging granular materials, specifically engineered for high-volume rice producers. This turnkey solution minimizes labor and maximizes throughput.

Integrating world-class components from Mettler Toledo and Panasonic, this servo-driven line handles 5-25kg bags at an exceptional speed of up to 900 bags/hour.

Model: ZDB-900-Q8

Capacity: 550-900 bags/hour

System Type: Fully Integrated Automated Bagging Line

Key System Highlights

Uninterrupted High-Capacity Operation

The dual-station bag-giving system stores up to 300 bags and automatically alarms when low, ensuring continuous, non-stop production flow.

Intelligent Fault Rejection

Air pressure detectors monitor bag pickup and opening, automatically identifying and ejecting unqualified bags without interrupting the packing cycle.

Precision Servo Control

Powered by Panasonic servo motors, adjustments for different bag sizes are made electronically via the touch screen, eliminating time-consuming manual changes.

Elite Mettler Toledo Weighing

At its core is a Mettler Toledo weighing controller and Celtron load cells, delivering world-class accuracy and reliability for minimal product loss.

Technical Specifications

| Model | ZDB-900-Q8 |

| Packing Speed | 550 ~ 900 bags/hour |

| Package Weight Range | 5 ~ 25 kg |

| Applicable Bag Size Range (mm) | Length: 500-800, Width: 210-380 |

| Applicable Materials | Free-flowing granular materials such as rice, grains, seeds, pellets |

| Power Supply & Consumption | 380/220V Three-phase, five-wire / 6KW |

| Compressed Air Requirements | 0.4~0.6MPa / 15m³/h |

| Bag Magazine Capacity | 100 ~ 300 bags |

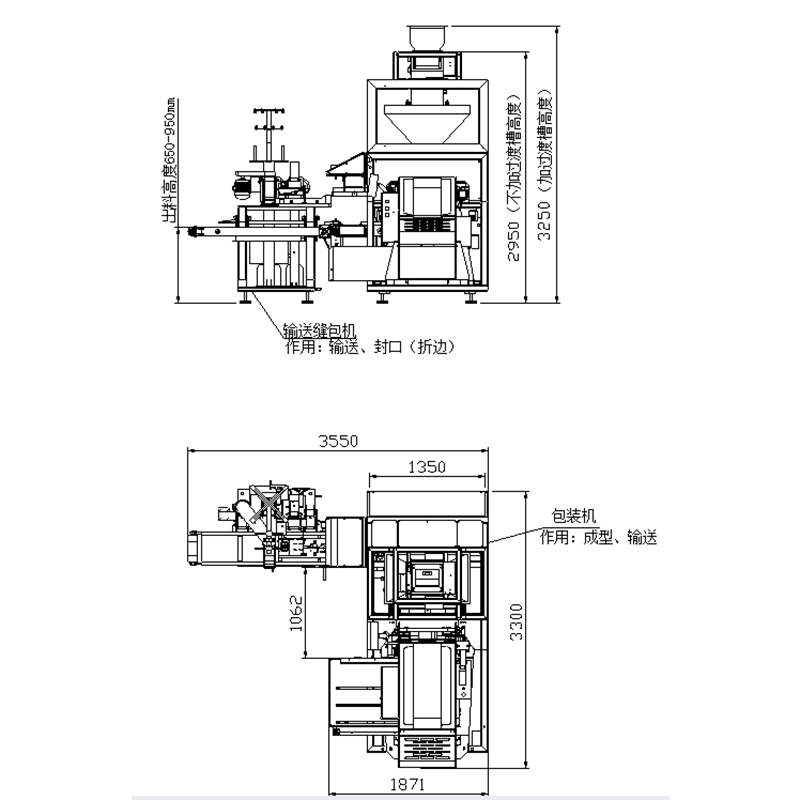

| Overall Dimensions (L×W×H mm) | 3520 × 3257 × 3250 |

In-Depth System Information

A Complete, End-to-End Packaging Workflow

The Automatic 25kg Rice Bagging Machine ZDB-900-Q8 is a comprehensive production line designed for maximum automation. The system integrates the following key stations into one fluid process:

| Mechanism Description | Quantity |

|---|---|

| Automatic Bag-Giving Machine | 1 Set |

| High-Speed Weighing Scale | 1 Set |

| Main Packing Machine | 1 Set |

| Conveyor with Integrated Bag Folding & Stitching Machine | 1 Set |

This automated workflow includes stable bag clamping, precise filling via an independent discharge system, and a perfectly synchronized conveyor with a mechanical linkage to prevent bag deflection, ensuring a seamless and reliable operation from start to finish.

Engineered with Best-in-Class Global Components

To achieve the highest level of performance, this automatic rice packer line is built with components sourced from world-renowned leaders in industrial technology, guaranteeing precision, durability, and a long operational lifespan.

| No. | Component Name | Brand / Controller |

|---|---|---|

| 1 | Touch Screen (weighing controller) | Switzerland / Mettler Toledo |

| 2 | Load Cells | USA / Celtron |

| 3 | Power Switch | Japan / Omron |

| 4 | Limit Switch | Japan/Omron & Zhengtai |

| 5 | Miniature Circuit Breaker | France / Schneider |

| 6 | Button, Knob | France / Schneider |

| 7 | Intermediate Relay | Japan / Omron |

| 8 | Cylinder | Taiwan / AirTac |

| 9 | Electric Cylinder | Japan / SMC, IAI |

| 10 | Solenoid Valve | Taiwan / Airtac |

| 11 | Servo Motor | Japan / Panasonic |

| 12 | Motor | China / Gaoqi |

| 13 | Vacuum Pump | Germany / Leybold |

| 14 | Folding Machine / Traction Machine | "Qinggong" QG4900 |

| 15 | Stitching Machine | Newlong DS-9CW |

Quality, Service, and Corporate Responsibility

Our Quality Commitment: Each packaging line undergoes a strict quality assurance protocol, including individual component testing and a mandatory 48-hour continuous operational trial before dispatch to ensure it meets our exacting standards.

Comprehensive Service: We provide full end-to-end service, from expert consultation and layout planning to on-site installation, commissioning, and staff training. Our after-sales support includes lifetime technical assistance and prompt spare parts availability.

Corporate Social Responsibility: Our designs prioritize energy efficiency to reduce our customers' carbon footprint. By enabling high-speed, accurate packaging, our machines help minimize product waste and material loss, contributing to a more sustainable food supply chain.

Frequently Asked Questions (FAQ)

Q1: What are the main advantages of using servo motors?

A1: Servo motors offer superior precision, speed, and repeatability compared to standard motors. In this system, it means that when you need to switch from a 10kg bag to a 25kg bag, all physical adjustments are made automatically and precisely through the software on the touch screen, drastically reducing changeover time and eliminating human error.

Q2: How does the system ensure the bag is always opened correctly?

A2: The machine uses a large "finger" cylinder specifically designed to get inside the bag opening and ensure it is wide and smooth. This is combined with air pressure sensors that confirm a successful bag-open action before any material is discharged, preventing spills and waste.

Q3: Is this system only suitable for a 25kg rice bag, as the name suggests?

A3: While it is exceptionally well-suited for a 25kg rice bagging operation, the system is highly flexible. It is designed to handle a full weight range from 5kg to 25kg and is applicable to a wide variety of granular materials beyond rice, such as beans, seeds, sugar, and animal feed.