DCS-50CS-Q5 High-Speed Vibratory Feeder Bagging Machine

DCS-50CS-Q5 High-Speed Packing Scale with Vibratory Feeder

Engineered for speed, precision, and versatility, this bagging system utilizes an advanced vibratory feeding mechanism. This makes it the ideal solution for gently handling a wide range of granular materials, including fragile or irregularly shaped products.

Combining dual-hopper weighing with high-quality components, this machine delivers consistent high performance and reliability for diverse sectors like agriculture, food production, and chemical industries. It represents the pinnacle of modern grain and fertilizer bagging equipment.

Model: DCS-50CS-Q5

Capacity: 600-720 bags/hour

Core Technology: Vibratory Feeder System

Key Advantages

Gentle & Versatile Handling

The vibratory feeding system ensures smooth, clog-free handling of a wide range of granular materials, including those with irregular shapes or fragile textures, minimizing product damage.

High-Speed Weighing

Equipped with a dual feeding and weighing mechanism, this machine achieves high throughput rates, significantly improving the yield and efficiency of your entire grain or fertilizer bagging system.

Reliable & Precise Operation

Built with globally recognized components, including a high-precision controller and premium pneumatic elements, for stable, accurate weighing with automatic error correction.

Durable & Easy to Maintain

Constructed with stainless steel for all parts in contact with the material, ensuring a long service life and simple cleaning. Its user-friendly design includes easy operation and fault auto-diagnosis.

Technical Specifications

| Model | DCS-50CS-Q5 (Vibratory Feeder) |

| Weighing Extent | 20 - 50 kg per bag |

| Operation Speed | 600 - 720 bags/hour |

| Accuracy Grade | Class X(0.2) |

| Scale Interval (Resolution) | 10 g |

| Power Supply & Consumption | 4N-AC 380V, 50Hz, 3 KW |

| Air Supply & Consumption | 0.4~0.6 MPa, 1.5 m³/h |

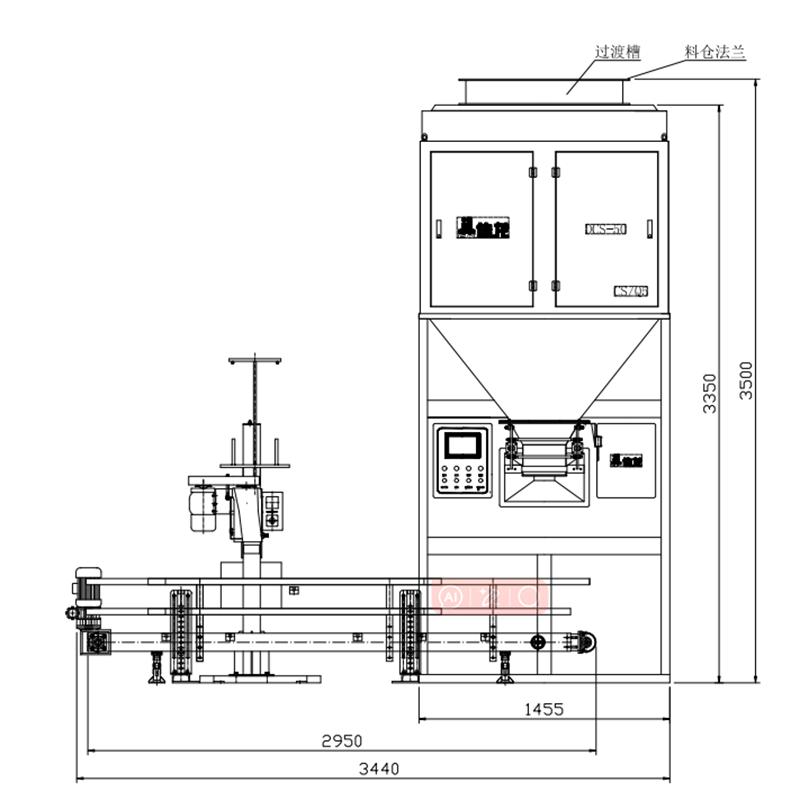

| Installation Height | 3500 mm |

Main Component Configuration

| Component | Brand / Supplier |

| Weighing Controller | Canada/General Measure |

| Switching Power Supply | TW/Meanwell |

| Button | French/Schneider |

| Load Cell | US/Celtron |

| Pneumatic Components (Cylinder, Solenoid Valve) | TW/Airtac |

Versatile Application Scenarios

1

Agricultural Sector

The ideal fertilizer bagging equipment. Also perfect for any grain bagging system, handling seeds, rice, beans, and feed pellets with gentle precision.

2

Food Production

Excellent for packaging bulk food ingredients such as sugar, salt, corn, and irregularly shaped snack foods or nuts without causing breakage.

3

Chemical Industry

Effectively bags plastic granules, masterbatch, resin particles, and other non-corrosive chemical materials, making it a reliable automatic big bag filling machine.

4

Portable & On-Site Use

The machine's robust design also lends itself to use as a portable bagging machine for on-site projects or mobile bagging operations.

In-Depth Product Details

Operational Workflow

The workflow is designed for maximum efficiency. An operator manually places an empty bag on the filling spout and presses the start switch. The machine automatically clamps the bag. The advanced vibratory feeder evenly and quickly transports material into the weighing hoppers. Once the target weight is reached, the material is discharged into the bag. The bag is then released onto an optional conveyor, ready for sealing. This blend of manual and automatic processes makes it a highly effective semi-automatic solution.

Engineering & Quality Assurance

We prioritize robust construction and reliable performance. This machine is built with a sturdy frame and utilizes high-quality stainless steel for all parts that make contact with the material, ensuring hygiene and corrosion resistance. Our vibratory feeding system is meticulously calibrated for optimal performance. Before shipment, every machine undergoes a rigorous quality control process, including endurance testing and accuracy verification, to ensure it delivers dependable and precise results in your production environment.

Our Commitment to Your Success

Expert Consultation: Our team will help you evaluate your material's characteristics to ensure the vibratory feeding system is the perfect match for your needs, whether for a fertilizer bagging equipment line or a food packaging system.

After-Sales Support: We provide comprehensive installation guidance, operator training, and a full machine warranty. Our commitment includes lifelong technical assistance for any questions or issues.

Spare Parts Availability: We maintain a full inventory of all essential components—including controllers, load cells, and pneumatic parts—to ensure any potential downtime is minimized.

Data Connectivity: A reserved RS232/485 interface allows for easy integration with your plant's data management and control systems.

Frequently Asked Questions (FAQ)

Q1: Why choose a vibratory feeder over other types?

A: A vibratory feeder is ideal for materials that are fragile, irregularly shaped, or prone to interlocking. The smooth vibration provides a consistent flow without the use of augers or belts that could damage the product. It is exceptionally versatile and handles a wider variety of materials effectively.

Q2: Is this machine suitable for an "automatic bigbag filling system"?

A: While this specific model is designed for open-mouth bags in the 20-50 kg range, the same high-quality components and control principles are used in our larger automatic big bag filling machines. This unit is perfect for establishing a high-speed semi-automatic line that can be a step towards or a complement to a larger big bag system.

Q3: What kind of operator involvement is needed?

A: This is a semi-automatic machine. An operator is responsible for placing empty bags on the filling spout. The machine then handles all weighing and filling operations automatically, maximizing the operator's efficiency.