High-Speed Automatic Weighing and Bagging Line

Fully Automatic High-Speed Granule Packaging System

This fully automatic weighing and bagging machine is engineered for high-throughput, unmanned packaging of various granular materials. It provides a complete, integrated solution for industrial-scale operations, automating every step from bag feeding and high-precision weighing to filling and secure bag closing.

It is the ideal automated system for ensuring speed, accuracy, and efficiency in your production line.

Capacity: 550 - 900 bags/hour

Weighing Range: 5kg - 25kg

Bag Types: PP Woven Gusseted Bags

Diverse Application Scenarios

1

Agriculture & Food Processing

Ideal for high-volume, automatic packaging of staple materials such as rice, grains, beans, sugar, salt, and various seeds for commercial distribution.

2

Animal Feed & Nutrition

Perfectly suited for automated bagging of animal feeds, birdseed, and other pelleted nutritional products into PP woven bags.

3

Pet Care Industry

An efficient solution for the high-speed packaging of bulk pet products like cat litter, dog food kibble, and other granulated materials.

4

Industrial & Chemical Sector

Effectively handles the automatic bagging of industrial products like plastic resin pellets, salt, fine minerals, and other free-flowing granules.

Core Technical Advantages

Fully Automated, Uninterrupted Workflow

This system is designed for maximum efficiency, featuring a double working station bag-giving system that can store 100-300 bags per station. Detectors provide an alarm if a station is running low, allowing an operator to reload it while the other station continues to feed the line, ensuring continuous, non-stop production.

Intelligent & Stable Bag Handling

Air pressure detectors are active throughout the bag handling process (picking, opening, clamping, filling). Any unqualified bags are automatically identified and kicked out without halting operations. The machine uses independent systems for the bag-clamping movement and the discharge gate, providing superior stability. A large finger cylinder ensures the bag mouth is held open wide and smooth for efficient filling.

Servo-Driven for Precision and Ease of Use

All major motoring functions are controlled by high-performance Panasonic servo motors. This allows for fast, precise, and repeatable adjustments for different packing specifications. Changing bag sizes or product parameters is easily done via the touch screen controller, with no need for complex manual adjustments.

Technical Specifications and System Composition

| Parameter | Value |

| Packing Speed | 550-900 bags/hour |

| Package Weight | 5-25kg |

| Bag Size Range (mm) | L: 500-800, W: 210-380 |

| Bag Storage Capacity | 100-300 pcs per station |

| Air Pressure / Consumption | 0.4-0.6MPa / 15m³/h |

| Power Supply / Consumption | 380V/220V / 6KW |

| Overall Dimensions (L×W×H, mm) | 3520 × 3257 × 3250 |

Premium Component Configuration

Our commitment to long-term reliability is reflected in our choice of world-class components from leading international brands.

| Component Description | Brand / Origin |

| Touch Screen (weighing controller) | Switzerland / Mettler Toledo |

| Load Cells | USA / Celtron |

| Power Switch & Intermediate Relay | Japan / Omron |

| Limit Switch | Japan / Omron & China / Zhengtai |

| Miniature Circuit Breaker, Button, Knob | France / Schneider |

| Cylinder & Solenoid Valve | Taiwan / AirTac |

| Electric Cylinder | Japan / SMC, IAI |

| Servo Motor | Japan / Panasonic |

| Motor | China / Gaoqi |

| Vacuum Pump | Germany / Leybold |

| Stitching Machine | Japan / Newlong |

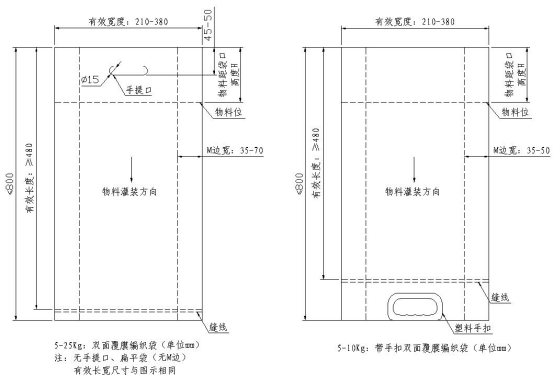

Bag Specifications for Optimal Performance

To achieve maximum speed and reliability, bags must meet specific quality, handling, and dimensional standards. All customer bags must be tested and approved by our engineers.

Material and Handling Requirements:

Bags must be double-sided laminated PP woven material.

Hardness of the front and back of the bag must be consistent and bags must be flat, without sticky printing, bent corners, or sealed mouths.

If a plastic handle is present, it must be located at the bottom of the bag.

Bags must be stored flat in stacks of no more than 50, with stacks shifted 100 mm to relieve pressure from the opening.

M-Gusseted Bag Dimensions (Unit: mm):

For 5kg Bags: L 480-520, W 210-250, Gusset 35-50

For 10kg Bags: L 580-620, W 260-290, Gusset 35-50

For 25kg Bags: L 750-780, W 340-380, Gusset 45-70

Required Headspace After Filling (H):

10kg Bags: ≥180mm (no handle/fold) or ≥220mm (with handle/fold)

25kg Bags: ≥230mm (no handle/fold) or ≥270mm (with handle/fold)

Our Service & Support Commitment

Pre-Sales Technical Consultation: Our team works closely with you to analyze your product, bags, and production goals to ensure our machine is the perfect fit for your operation. Bag testing is a mandatory step to guarantee performance.

After-Sales Support & Training: We offer comprehensive after-sales support, including installation guidance, detailed operator training, and lifetime technical assistance. With a ready stock of critical spare parts, we are dedicated to maximizing your uptime and ensuring your long-term success.