KL-300Y Automatic Sachet Packaging Machine for Liquids & Pastes

KL-300Y Liquid Sachet Packer

A compact and reliable VFFS machine engineered for packaging liquids and pastes. It combines high-precision volumetric dosing with a built-in date coder and user-friendly operation, making it ideal for small to medium-scale production.

Model: KL-300Y

Capacity: 20-40 bags/minute

Key Feature: Piston Pump Dosing System

Product Highlights

High-Precision Dosing

Utilizes an accurate piston pump measurement method, ideal for consistent volumes of liquids and pastes.

Integrated Date & Batch Coding

Includes a ribbon coding machine capable of printing three lines of text for dates and batch numbers.

Professional, Easy-Open Bags

Creates secure three-sided seal sachets with a tooth-shaped cut for a convenient easy-tear opening.

Automatic Film Alignment

A color code detection function ensures that each bag is cut and sealed perfectly, reducing film waste.

Technical Specifications

| Parameter | Value |

| Model | KL-300Y |

| Bag Type | Three-sided seal |

| Measurement Method | Piston Pump (with 30L Hopper) |

| Measurement Range | 50 ~ 200 ml |

| Bag Size | Width: 30-130mm, Length: 50-200mm |

| Packaging Speed | 20 - 40 bags/minute |

| Cutting Method | Standard tooth cutting (easy-tear) |

| Coding Machine | Ribbon Coder (3 lines, 12 characters/line) |

| Voltage | 1P / 220V / 50HZ |

| Power | 1.5 KW |

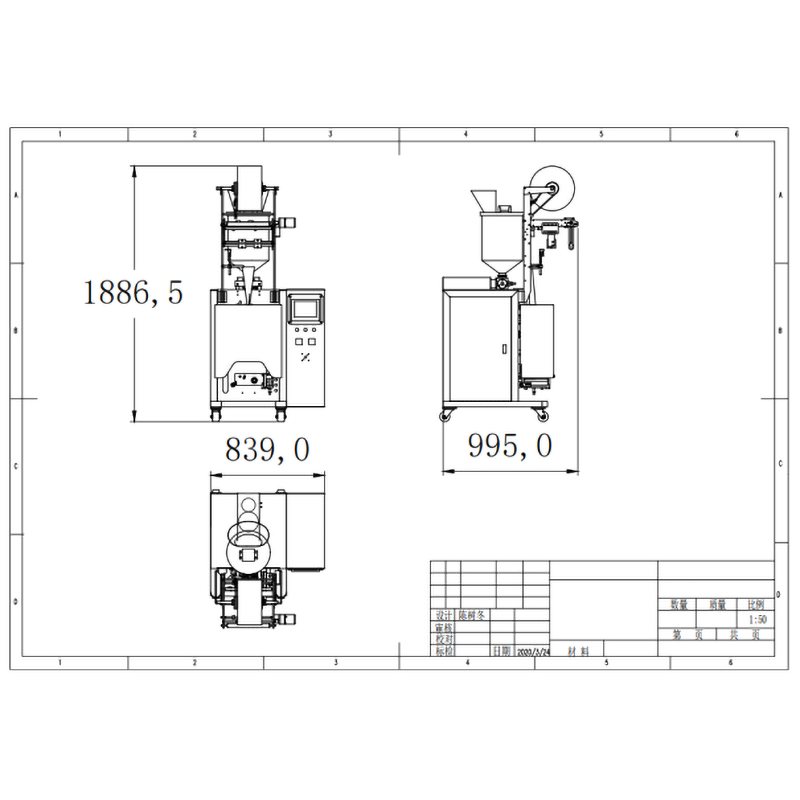

| Equipment Size (L*W*H) | 1000 * 850 * 1850 mm |

| Equipment Weight | 260 kg |

Application Scenarios

1

Food & Condiments

Ideal for packaging ketchup, mustard, salad dressing, soy sauce, honey, jam, and cooking oil.

2

Cosmetics & Personal Care

Perfect for shampoo, conditioner, lotions, liquid soaps, and single-use cosmetic creams.

3

Pharmaceuticals & Health

Excellent for syrups, liquid supplements, herbal pastes, and single-dose medicinal liquids.

4

Household & Chemical

Suitable for non-corrosive liquid detergents, cleaning agents, adhesives, and gels.

Frequently Asked Questions (FAQ)

Q1: Can this machine handle very thick pastes?

A1: The standard piston pump is excellent for a wide range of liquids and semi-liquids. For very thick, high-viscosity pastes (e.g., peanut butter), an upgraded pump system or a model with a heated/agitated hopper may be required. Please consult our team and provide a sample of your product for evaluation.

Q2: Is it difficult to change the filling volume or the bag size?

A2: No, it is designed to be user-friendly. The filling volume is easily adjusted on the piston pump. Changing the bag size requires swapping out the "bag making mold," which is a standard and straightforward mechanical adjustment.

Q3: What power supply does the machine need?

A3: The KL-300Y is highly efficient and runs on a standard single-phase 220V / 50HZ power supply. This makes it easy to install in a wide variety of facilities without the need for specialized three-phase electrical wiring.