Fully Automatic High-Speed Bagging System - Model ZDB-900-Q30

High-Throughput Automated Packaging Line

Engineered for maximum efficiency, this fully automatic bagging machine provides a complete, high-speed solution for packing grains and other particle materials. It is the ideal choice for large-scale production in the rice, seeds, sugar, and greater food processing industries.

This integrated system automates the entire process from bag feeding and high-speed weighing to filling and final bag sealing, delivering unparalleled performance and reliability.

Model: ZDB-900-Q30

Capacity: Up to 900 bags/hour

Material: Robust steel construction with premium components

Ideal Application Scenarios

1

Large-Scale Rice Milling

Maximize output in commercial rice mills, automating the packaging of various rice types for wholesale and retail markets.

2

Seed Processing Plants

Gently and accurately package high-value agricultural seeds, maintaining product integrity for commercial distribution.

3

Sugar Refineries

Handle high-volume packaging of granulated sugar, ensuring a continuous and efficient flow from production to dispatch.

4

Food Commodity Industry

Perfect for packing bulk particle material such as beans, pulses, pet food kibble, and other grains for commercial sale.

Key System Advantages

High-Speed Automation

Achieve packaging speeds of 550 to 900 bags per hour, significantly boosting your operational throughput and reducing labor costs.

Intelligent Error Rejection

Equipped with air pressure detectors, the system automatically identifies and rejects unqualified bags without stopping the line, ensuring seamless operation.

Servo-Driven Precision

Powered by Panasonic servo motors, it allows for quick, precise adjustments for different packing specifications directly from the controller.

Premium Global Components

Integrates top-tier components from brands like Mettler Toledo, Omron, Schneider, and Festo to guarantee reliability and stable performance.

Technical Specifications & Composition

System Composition:

| Mechanism Description | Quantity |

| Auto Bag-Giving Machine | 1 Set |

| High-Speed Weighing Scale | 1 Set |

| Packing Machine (Main Unit) | 1 Set |

| Conveyor with Stitching Machine Assembly | 1 Set (Includes feed-in unit and stitching head) |

Technical Data:

| Parameter | Value |

| Model | ZDB-900-Q30 |

| Speed | 550-900 bags/hour |

| Weighing Range | 5kg ~ 25kg |

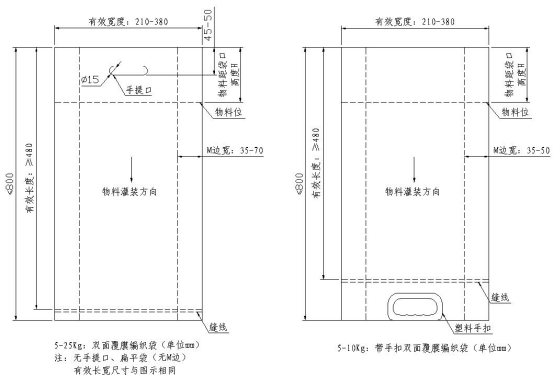

| Bag Size Range (mm) | Length: 500-800, Width: 210-380 |

| Bag Storage Capacity | 100~300 pcs |

| Power/Consumption | 380/220V Three-phase five-wire, 6KW |

| Air Pressure / Consumption | 0.4~0.6 MPa, 15m³/h |

| Overall Dimensions (L×W×H, mm) | 3550 × 3700 × 3250 |

Main Configuration and Brand List

We build our systems to a standard of quality and reliability, achieved by exclusively using components from globally recognized leaders in industrial automation.

| No. | Component Name | Brand / Origin |

| 1 | Touch Screen & Weighing Controller | Japan/Omron & Switzerland/Mettler Toledo |

| 2 | Load Cells | USA/Celtron |

| 3 | Power Switch | Japan/Omron |

| 4 | Limit switch | Japan/Omron & China/Zhengtai |

| 5 | Miniature Circuit Breaker | France/Schneider |

| 6 | Button, Knob | France/Schneider |

| 7 | Intermediate Relay | Germany/Siemens |

| 8 | Cylinder | Germany/Festo |

| 9 | Electric Cylinder | Japan/SMC, IAI |

| 10 | Solenoid Valve | Taiwan/Airtac |

| 11 | Servo Motor | Japan/Panasonic |

| 12 | Motor | China/Ziguang |

| 13 | Vacuum Pump | Germany/Leybold |

| 14 | Folding & Traction Machine "Qinggong" QG4900 | Jialong |

| 15 | Stitching Machine | Newlong Double Lines/4-threads |

In-Depth System Features & Bag Requirements

Advanced Mechanical and Control Design

This automated machine is built for stable, continuous operation. The bag-clamping mechanism and the material discharge gate utilize two independent systems, ensuring the bag is held securely during high-speed filling. A large finger cylinder is employed to guarantee that each bag mouth is opened wide and presented smoothly. For synchronized conveying, the plastic chain plate conveyor belt and upper guide mechanism are linked mechanically, preventing bag slippage or deflection.

Bag Requirements for Optimal Performance

To ensure flawless operation, the quality of bags is critical. All bags must be approved by Jialong and meet the following conditions:

Bags must be stored flat without any folding or creasing.

Stacks should not exceed 50 bags and must be shifted 100 mm relative to each other to relieve pressure.

Bags must be protected from damage during transport and storage.

The bag material and printing must not be sticky, and the bag mouth must open easily.

If a PE inner bag is used, it must be stitched, sealed, or glued to the outer bag at the mouth.

Customer Service & FAQ

Our Service Commitment

Pre-Sales Consultation: Our technical experts will work with you to understand your product, facility, and output goals to ensure the system is perfectly tailored to your needs.

After-Sales Support: We offer comprehensive installation guidance, operator training, and ongoing technical support. Our responsive team and ready supply of spare parts ensure your production line stays operational.

Frequently Asked Questions

1. How does the dual bag-giving station work?

The machine has two bag magazines (100-300 bags each). It feeds from one station, and if it runs low, an alarm alerts the operator to refill it while the machine continues working from the second station, ensuring non-stop production.

2. How are adjustments for different products made?

All major movements are controlled by servo motors. Adjustments for different packing specifications (within the machine's range) are easily made through the Omron touch screen interface, with no need for manual mechanical changes.

3. What happens if a bag is defective?

The machine uses intelligent sensors to detect anomalies. If a bag is faulty (e.g., stuck together, fails to pick up), the system automatically rejects that bag and immediately attempts to pick the next one, without stopping production.

4. What kind of bag closure does it use?

This system is configured with a high-quality Newlong industrial stitching machine that applies a secure double-line, four-thread stitch for a robust closure.