Fully Automatic Bagging & Sealing Line - Model ZDB-900-Q35

Versatile High-Speed Automatic Bagger with Dual Sealing

This fully automatic bag weighing and filling machine is engineered for high-speed, reliable packaging of a wide range of granular materials. It provides a complete, unmanned solution for industrial-scale weighing, filling, and sealing, boosting productivity while reducing labor costs.

With its innovative dual-sealing capability, it can seamlessly handle both stitched PP woven bags and heat-sealed PE or plastic bags, making it a truly versatile asset.

Model: ZDB-900-Q35

Capacity: Up to 900 bags/hour

Closure Options: Stitching and Heat Sealing

Broad Application Scenarios

1

Agriculture & Food Grains

Ideal for packaging rice, seeds, beans, and sugar in high volumes, ensuring product quality and packaging consistency for wholesale and retail markets.

2

Animal Feed & Nutrition

The stitching option is perfect for securely closing large PP woven bags used for livestock feed, grains, and other animal nutrition products.

3

Pet Care Products

The heat-sealing function is perfectly suited for producing retail-ready plastic or PE-lined bags of cat litter, kibble, and other pet food products.

4

Industrial & Building Materials

As an automatic sandbag filler, it is also highly effective for packaging sand, fine gravel, plastic resins, salt, and other granular industrial materials.

Advanced System Advantages

Non-Stop Operation

The dual-station bag-giving system stores up to 300 bags per station. It automatically continues working while an operator reloads an empty station, ensuring maximum uptime.

Ultimate Sealing Flexibility

This line integrates both an industrial stitching machine and a heat sealer, providing the ultimate flexibility to work with PP woven, paper, plastic, and PE-lined bags.

Smart Fault Diagnosis

Sensors detect bag pickup or opening failures and automatically eject the faulty bag without stopping production, minimizing waste and disruption.

Full Servo Control

Key movements are powered by high-precision servo motors, enabling fast, easy adjustments for different bag sizes directly through the touch-screen HMI.

Technical Specifications & Composition

| Parameter | Value |

| Model | ZDB-900-Q35 |

| Speed | 550-900 bags/hour |

| Weighing Range | 5kg ~ 25kg |

| Bag Size Range (mm) | L: 500-800, W: 210-400 |

| Heat Sealing Width Range (mm) | W: 210-400 |

| Bag Storage Capacity | 100 ~ 300 pcs |

| Power Supply / Consumption | 380/220V Three-phase five-wire, 6KW |

| Air Pressure / Consumption | 0.4 ~ 0.6 MPa, 15 m³/h |

| Overall Dimensions (L×W×H, mm) | 3550 × 4140 × 3250 |

Main Configuration: A Commitment to Quality

We build our systems to a standard of quality and reliability, achieved by exclusively using components from globally recognized leaders in industrial automation.

| No. | Component Name | Brand / Origin |

| 1 | Touch Screen (weighing controller) | Switzerland / Mettler Toledo |

| 2 | Load Cells | USA / Celtron |

| 3 | Power Switch | Japan / Omron |

| 4 | Limit switch | Japan / Omron & China / Zhengtai |

| 5 | Miniature Circuit Breaker | France / Schneider |

| 6 | Button, Knob | France / Schneider |

| 7 | Intermediate Relay | Germany / Siemens |

| 8 | Cylinder | Taiwan / AirTac |

| 9 | Electric Cylinder | Japan / SMC, IAI |

| 10 | Solenoid Valve | Taiwan / Airtac |

| 11 | Servo Motor | Japan / Panasonic |

| 12 | Motor | China / Ziguang |

| 13 | Vacuum Pump | Germany / Leybold |

| 14 | Folding Machine / Traction Machine | "Qinggong" QG4900 |

| 15 | Stitching Machine | Newlong Double Lines / 4-threads |

| 16 | Heat Sealer | China / Jialong |

Bag Quality & Handling Specifications

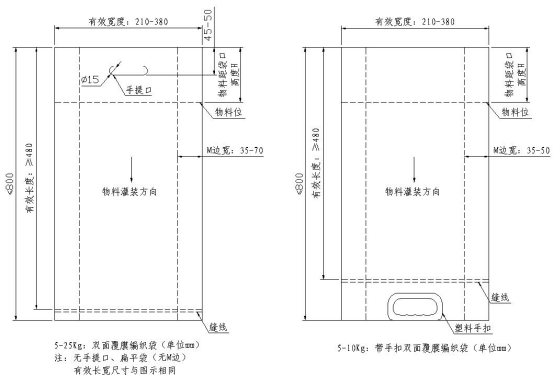

To ensure flawless performance and prevent jams, all bags must be approved by our team and adhere to the following material and handling requirements:

Bag Material & Quality Requirements:

PP Woven bags must be laminated on both sides with equal hardness. The bags must be flat, free of bent corners, and the mouth must not stick.

For bags with a plastic handle, the handle must be located at the bag's bottom, as filling occurs from the non-handle side.

M-gusset bags must have consistent front and back alignment, with a misalignment difference of less than 5mm.

Required Headspace After Filling (H):

10kg Bag: ≥180mm (no handle, no fold) / ≥220mm (with handle and fold)

25kg Bag: ≥230mm (no handle, no fold) / ≥270mm (with handle and fold)

Quality Assurance & Service

Quality Control and Testing

Every machine undergoes a rigorous quality control process, from raw material inspection to final assembly and performance testing. Before shipment, each system is run extensively to guarantee it meets our high standards for speed, accuracy, and reliability, ensuring it will perform flawlessly in your facility.

Frequently Asked Questions

1. Can this automatic bagger truly handle different types of bags?

Yes. It is uniquely equipped with both an industrial sewing machine for PP woven and paper bags, and a heat sealer for PE or plastic-lined bags. This provides the flexibility to switch between packaging types based on your product needs.

2. How are adjustments for different bag specifications made?

All major operational adjustments are handled through the user-friendly Mettler Toledo touch-screen interface. Because the system is controlled by servo motors, there is no need for manual or mechanical adjustments when switching between pre-programmed bag sizes or weights.

3. What kind of after-sales support do you offer?

We provide comprehensive support including pre-sales consultation, installation guidance, and operator training. Our after-sales service includes a full warranty, a ready supply of spare parts, and responsive technical assistance to ensure your production line maintains peak performance.