Fully Automatic Bagging & Sealing Line - Model ZDB-900-Q35

High-Capacity Automated Packaging Solution with Dual Sealing

This fully automatic bagging and sealing machine offers a complete, high-speed solution for packing various grains and other particle materials. It is the premier choice for large-scale operations in the rice, seeds, sugar, and greater food processing industries.

From automatic bag placing and high-precision weighing to filling and a secure final closure, this line streamlines your entire packaging process with exceptional speed and reliability.

Model: ZDB-900-Q35

Capacity: Up to 900 bags/hour

Sealing Options: Stitching and/or Heat Sealing

Key Operational Advantages

High-Speed Autonomous Operation

Reaches speeds of up to 900 bags/hour, utilizing a dual-station bag-giving system for continuous, uninterrupted production.

Versatile Dual-Sealing System

Equipped with both a Newlong stitching machine and a heat sealer, providing the flexibility to handle various bag materials like woven PP and PE-lined bags.

Intelligent Error Handling

Integrated sensors detect bag pick-up, opening, or clamping failures, automatically ejecting faulty bags without halting the entire line.

Full Servo-Motor Precision

All major movements are powered by high-performance Panasonic servo motors, enabling fast, accurate adjustments for different bag sizes via the HMI.

Ideal Application Scenarios

1

Industrial Rice & Grain Mills

Automate the packaging of rice, corn, wheat, and other grains in high-volume environments, preparing products for wholesale and retail markets.

2

Seed & Agribusiness Sector

Precisely weigh and gently handle high-value seeds, ensuring product integrity and accurate counts for commercial agricultural distribution.

3

Sugar Refineries & Food Ingredients

Maintain a high-speed, continuous workflow for packaging granulated sugar, salt, starches, and other particle-based food materials.

4

Pet Food & Animal Feed Production

The dual-sealing options make it perfect for packaging animal feed in stitched PP bags or pet food kibble in heat-sealed PE-lined bags.

Technical Specifications & Composition

| Parameter | Value |

| Model | ZDB-900-Q35 |

| Speed | 550-900 bags/hour |

| Weighing Range | 5kg ~ 25kg |

| Bag Size Range (mm) | L: 500-800, W: 210-400 |

| Heat Sealing Width Range (mm) | W: 210-400 |

| Bag Storage Capacity | 100 ~ 300 pcs |

| Power Supply / Consumption | 380/220V Three-phase five-wire, 6KW |

| Air Pressure / Consumption | 0.4 ~ 0.6 MPa, 15 m³/h |

| Overall Dimensions (L×W×H, mm) | 3550 × 4140 × 3250 |

Premium Component Configuration

We build our systems to a standard of quality and reliability, achieved by exclusively using components from globally recognized leaders in industrial automation.

| No. | Component Name | Brand / Origin |

| 1 | Touch Screen (weighing controller) | Switzerland / Mettler Toledo |

| 2 | Load Cells | USA / Celtron |

| 3 | Power Switch | Japan / Omron |

| 4 | Limit switch | Japan / Omron & China / Zhengtai |

| 5 | Miniature Circuit Breaker | France / Schneider |

| 6 | Button, Knob | France / Schneider |

| 7 | Intermediate Relay | Germany / Siemens |

| 8 | Cylinder | Taiwan / AirTac |

| 9 | Electric Cylinder | Japan / SMC, IAI |

| 10 | Solenoid Valve | Taiwan / Airtac |

| 11 | Servo Motor | Japan / Panasonic |

| 12 | Motor | China / Ziguang |

| 13 | Vacuum Pump | Germany / Leybold |

| 14 | Folding Machine / Traction Machine | "Qinggong" QG4900 |

| 15 | Stitching Machine | Newlong Double Lines / 4-threads |

| 16 | Heat Sealer | China / Jialong |

Bag Quality & Handling Requirements

To ensure flawless performance, bags must be approved by Jialong and meet the following material quality and handling conditions. These requirements prevent jams and ensure the highest operational efficiency.

Bag Material & Quality Requirements:

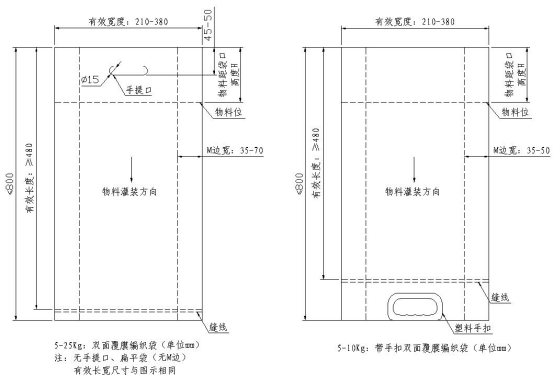

PP Woven bags must be laminated on both sides with equal hardness on the front and back. The bags must be flat, without bent corners or other defects.

The bag mouth must be clean and must not stick together.

If the bag includes a plastic handle, the handle must be located at the bottom of the bag, as filling occurs from the non-handle side.

For M-gusseted bags, the gusset must be consistent on both sides, with a misalignment difference of less than 5mm.

Required Headspace After Filling (H):

10kg Bag: ≥180mm (no handle, no fold) / ≥220mm (with handle and fold)

25kg Bag: ≥230mm (no handle, no fold) / ≥270mm (with handle and fold)

Our Commitment to You

Quality & Corporate Responsibility

We are committed to building superior industrial machinery. Every automatic bagger undergoes comprehensive quality assurance testing before shipment to guarantee performance. Our designs focus not only on high throughput but also on energy efficiency, minimizing environmental impact and reducing your operational costs. We believe in responsible manufacturing that supports the success and sustainability of our clients.

Frequently Asked Questions

1. Can the machine handle both paper and plastic-lined bags?

Yes. The dual-sealing system is one of its greatest strengths. It can use the stitching machine for standard PP woven or paper bags and the heat sealer for bags with a PE plastic inner liner, providing maximum packaging flexibility.

2. How is downtime minimized when reloading bags?

The system features two separate bag-giving stations. While one station is active, the other can be refilled by an operator. An alarm will notify you when a station is running low, allowing you to reload without ever stopping the machine.

3. How are adjustments made for different bag sizes?

Thanks to the servo-driven motors on all major axes, changing between different packing specifications (e.g., from a 10kg to a 25kg bag size) is easily done through the Mettler Toledo touch screen interface, eliminating the need for complex manual mechanical adjustments.