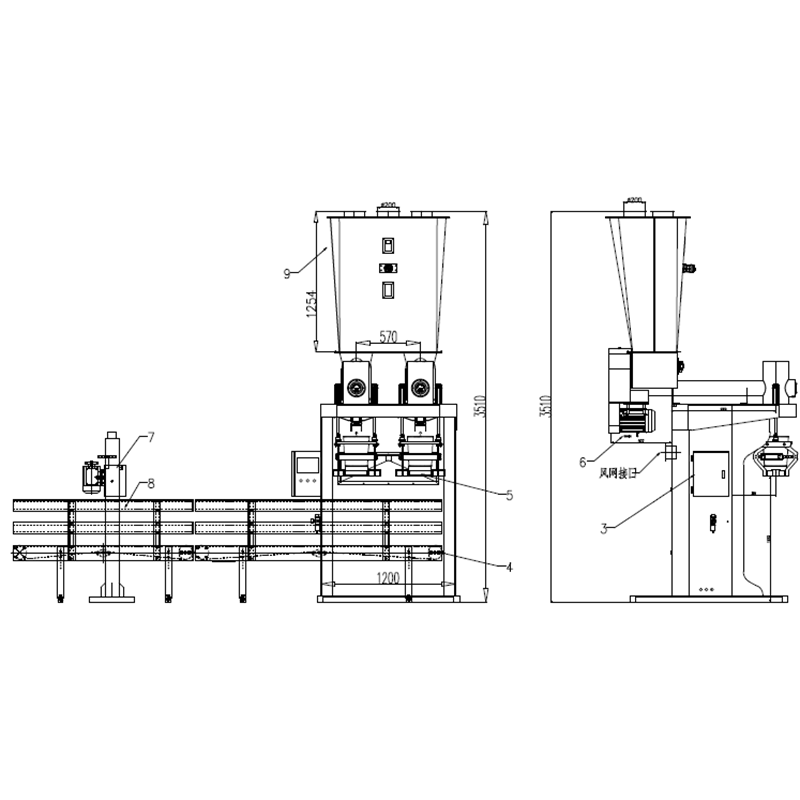

DCS-50-L2D High-Precision Auger Filling & Bagging Machine for Powders

DCS-50-L2D High-Precision Auger Packer

A heavy-duty, automatic bagging machine engineered for the precision packaging of non-free-flowing powders. By integrating world-class components, it delivers unmatched reliability and accuracy for demanding industrial environments.

Model: DCS-50-L2D

Capacity: 300-350 bags/hour

Key Feature: High-Accuracy Auger Feeding System

Product Highlights

High-Precision Auger Feeding

The specialized auger system provides a consistent dose, making it ideal for difficult, non-free-flowing powders.

Powered by World-Class Parts

Built with an elite selection of components including an ABB motor, Schneider electrics, SMC pneumatics, and NSK bearings.

Exceptional Weighing Accuracy

Engineered to achieve an outstanding accuracy grade of 0.2%FS (Full Scale) to minimize product giveaway.

Robust, High-Throughput Design

Efficiently handles a large weighing range of 25 to 50 kg at a speed of 300 to 350 bags per hour.

Technical Specifications

| Parameter | Value |

| Model | DCS-50-L2D |

| Weighing Range | 25 - 50 kg |

| Operational Speed | 300 - 350 bags/hour |

| Feeding Method | Auger (Screw) Feeder |

| Accuracy Grade | 0.2%FS (Full Scale) |

| Air Pressure | 0.4 ~ 0.6 MPa |

| Power Supply | AC 380V / 50HZ |

| Working Condition | Temperature: 0-40°C, Relative Humidity: ≤90% |

| Primary Materials | Food-Grade SUS304 Stainless Steel (Contact Parts), Carbon Steel Frame |

Application Scenarios

1

Food & Ingredient Industry

Ideal for flour, milk powder, starch, cocoa powder, ground spices, and food additives.

2

Chemical Industry

Perfect for dry chemical powders, detergents, dyes, plastic additives, and fine mineral powders.

3

Agricultural Sector

Excellent for powdered feed additives, soluble fertilizers, and pesticides.

4

Building Materials

Suitable for bagging cement, dry mortar mix, tile adhesive powder, gypsum, and wall putty.

Main Configuration & Technical Advantage

World-Class Component Integration

We integrate globally recognized, high-performance components to ensure our machinery provides maximum reliability, efficiency, and a long service life, even in the most demanding industrial conditions.

| No. | Name | Brand | Technical Advantage |

| 1 | Touch Screen | Xinjie | Provides a clear, intuitive user interface for easy operation and monitoring. |

| 2 | Load Cell | Keli | A highly sensitive and durable load cell that forms the basis of our precision weighing system. |

| 3 | Cylinder | SMC | Premium Japanese pneumatics ensure millions of fast, reliable, leak-free cycles, reducing maintenance. |

| 4 | Motor | ABB | A globally leading motor that delivers stable, high-torque, energy-efficient power for the auger drive. |

| 5 | Electrical Element | Schneider | Top-tier French electrical components guarantee safe, stable power distribution and circuit control. |

| 6 | Bearing | NSK | High-quality Japanese bearings provide smooth, durable operation and a long lifespan for moving parts. |

Frequently Asked Questions (FAQ)

Q1: What makes an auger feeder better than other types for my product?

A1: An auger (screw) feeder is essential for materials that do not flow easily, such as fine powders. The auger actively pushes the material into the bag at a controlled rate, ensuring an accurate fill where a gravity feeder would fail.

Q2: How is dust controlled during the filling process?

A2: The machine is designed with an integrated dust collection port around the filling nozzle. This allows you to connect the machine to your factory's dust extraction system to maintain a clean and safe working environment.