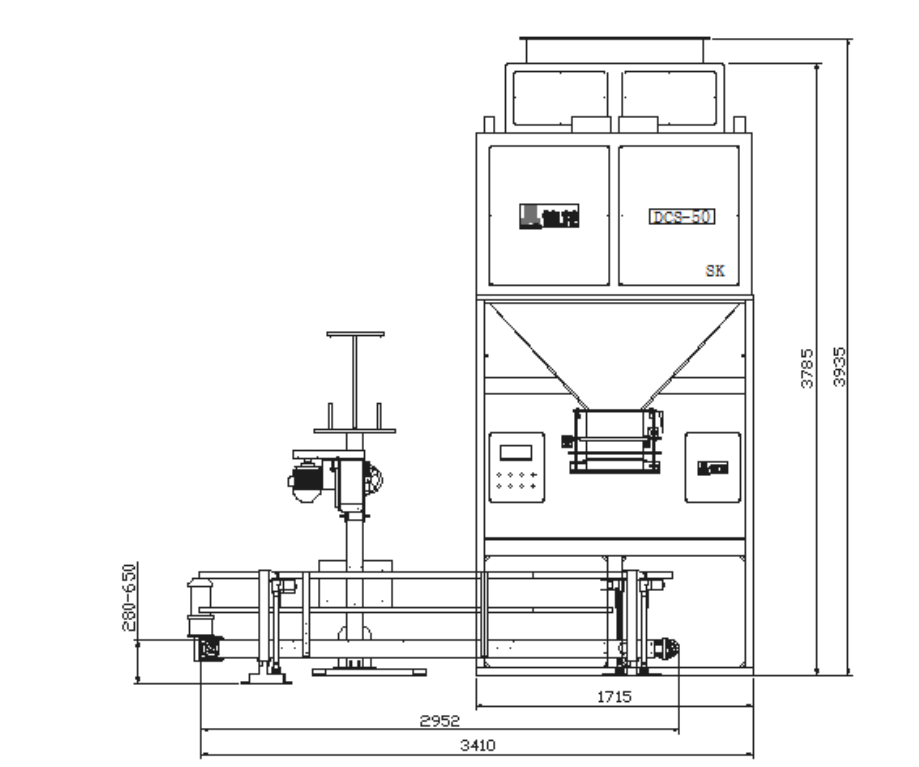

DCS-50SK Rice Bran Packing Machine

DCS-50SK Specialized Packaging Machine for Low-Density Materials

Master the art of packaging challenging, low-density materials with the DCS-50SK. This semi-automatic packaging machine is expertly engineered to handle rice bran, wheat bran, chaff, and other grain husks with unparalleled efficiency and precision.

Combining an advanced weighing system with a robust, integrated design including an electric lifting conveyor, this machine offers a reliable and cost-effective solution for agricultural and food processing industries.

Model: DCS-50SK

Weighing Range: 40 - 50 kg

Capacity: 360 - 420 bags/hour

Key Advantages

Optimized for Low-Density Materials

Specifically designed for quantitative packaging of rice bran, wheat bran, and other lightweight husks, ensuring accurate fills for challenging products.

High Precision & Stability

This rice bran packing machine utilizes imported technology, including high-quality sensors and pneumatic actuators, for stable performance and reliable accuracy (Class X(0.5)).

Smart Automated Features

Equipped with automatic error correction, over/under tolerance alarms, and fault self-diagnosis to minimize operator error and ensure consistent quality.

Durable & Hygienic Design

All parts in contact with materials are made of stainless steel for a long service life and easy cleaning, meeting industry hygiene standards.

Technical Specifications

| Parameter | Model: DCS-50SK |

| Weighing Range | 40 - 50 kg |

| Packaging Speed | 360 - 420 bags/hour |

| Weighing Accuracy | Class X(0.5) |

| Resolution (Scale Interval) | 10 g |

| Power Requirement | 4N-AC 380V / 50Hz, 1 KW |

| Air Requirement | 0.4~0.6 MPa, 1 m³/hour |

| Installation Height | 3950 mm |

Main Component Configuration

| Component | Brand / Supplier |

| Weighing Controller | China/Zhiyuanda |

| Low-Voltage Electricals (Button, etc.) | France/Schneider |

| Load Cell Sensor | USA/Celtron |

| Power Switch | Taiwan/Meanwell |

| Motor | China/Hanseng/Sanjing |

| Pneumatic Elements | Taiwan/Airtac |

| Sewing Machine | China/Qinggong |

Application Scenarios

1

Grain Milling Byproducts

The definitive solution for accurately bagging light, bulky materials. This rice bran packing machine is perfect for both coarse rice bran and fine wheat bran, ensuring consistent package weights.

2

Animal Feed Production

Ideal as a chaff packaging machine for producing animal feed. Its ability to handle light, fibrous materials makes it perfect for incorporating bran and chaff into feed mixtures before packaging.

3

Agricultural Waste & Biomass

Effectively packages other low-density agricultural byproducts such as chopped straw, sawdust, or other forms of biomass for fuel or bedding.

4

Specialty Powders

This bran filling machine can also be adapted for other light industrial powders that have poor flow characteristics and require specialized feeding mechanisms to ensure accurate weighing.

In-Depth Details

Operational Workflow

The workflow of the DCS-50SK is streamlined for ease of use and high productivity. An operator manually places an empty bag onto the filling spout and initiates the cycle. The bran filling machine's controller takes over, automatically clamping the bag and activating the feeding system. Material is precisely weighed into the hopper. Once the target weight is reached, the contents are cleanly discharged into the bag. The bag is then released onto the electrically powered lifting conveyor, which moves it to the integrated sewing station for a secure, automatic stitch closure.

Our Commitment to Quality and Social Responsibility

We engineer solutions built to last. This chaff packaging machine is constructed with a heavy-duty frame and high-quality components from leading international suppliers to ensure stability and a long operational lifespan. By automating a physically demanding task, this machine improves workplace safety and ergonomics. Its high efficiency and accuracy also help reduce material waste, contributing to more sustainable and responsible production practices for our clients. Every machine undergoes a thorough quality inspection before shipment.

Comprehensive Customer and Technical Support

Expert Consultation: Our technical team will work closely with you to analyze your specific material (e.g., rice bran vs. wheat bran) to ensure the machine is optimally configured for your production needs.

Full Technical Assistance: We provide detailed user manuals and remote engineering support to assist with installation, setup, and operator training, ensuring you achieve maximum performance.

Guaranteed Spare Parts Service: We maintain a full inventory of all essential spare parts to ensure fast delivery and minimize potential production downtime.

Frequently Asked Questions (FAQ)

Q1: Why is this machine specialized for rice bran and chaff?

A: Rice bran, chaff, and similar husks are very light, bulky, and have poor flow characteristics. They can easily bridge or clog in standard gravity-fed packaging machines. The DCS-50SK uses a specialized feeding mechanism (likely vibratory or auger-assisted) designed to handle these difficult materials, ensuring a consistent flow for accurate weighing.

Q2: Is this a fully automatic or semi-automatic machine?

A: This is a semi-automatic system. It automates the critical parts of the process—weighing, filling, and sewing—but requires an operator to manually place each empty bag onto the filling spout. This provides an excellent balance of high efficiency and cost-effectiveness.

Q3: What does the "electric lifting conveyor" do?

A: The conveyor belt's height can be electrically adjusted up or down. This is important for accommodating bags of different lengths. By raising or lowering the conveyor, you can ensure the top of the bag is at the correct height for the sewing machine, regardless of whether you are filling a shorter 40kg bag or a longer 50kg bag.