LZB-1200-R40/A Automatic Vacuum Packaging Machine

The Efficient and Intelligent Solution for Brick-Shaped Packaging

Introducing the LZB-1200-R40/A Automatic Vacuum Packaging Machine, a state-of-the-art solution designed for the food and grain industries. This machine seamlessly integrates precise quantitative weighing, high-speed vacuum sealing, and perfect brick-shaping.

It is engineered to provide your products with packaging that is both protective and aesthetically pleasing, significantly enhancing product value and market competitiveness.

Model: LZB-1200-R40/A

Speed: 1000 ~ 1200 bags/hour

Weighing Range: 0.3 ~ 5 kg

Product Highlights

Exceptional Efficiency, Multiplied Output

Features an innovative four-station design with dual vacuum chambers, completing four packages in a single cycle at speeds up to 1200 bags/hour.

Versatile Range, One Machine

Accommodates a wide 0.3kg to 5kg range. Its unique vacuum-shaping mechanism adapts flawlessly to bags of varying thicknesses for a perfect shape.

Precision Weighing, Guaranteed Quality

Employs two-stage cylinder and vibration feeding technology, resulting in faster speeds and a superior measurement accuracy of X(0.5).

Intelligent & User-Friendly

Designed with a fixed, single-person bag-loading station. Features include an automatic lifting bag magazine and error detection alarms.

Technical Specifications

| Parameter | Details |

| Model | LZB-1200-R40/A |

| Weighing Extent | 0.3 ~ 5 kg |

| Speed | 1000 ~ 1200 bags/h |

| Accuracy | X(0.5) |

| Power/Consumption | 4N-AC 380V 50Hz / 13.5KW |

| Air Consumption | 0.4~0.6MPa / 40m³/h |

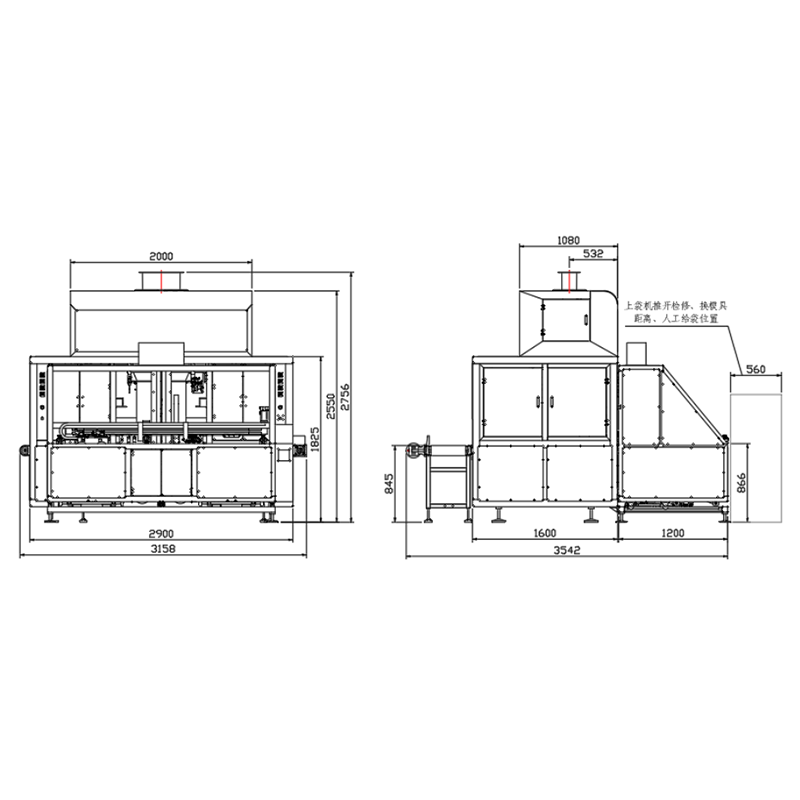

| Dimensions (L×W×H) | 3150 × 3550 × 2760 mm |

Core Component Configuration

| Name | Supplier |

| Touch Screen 10" | Germany / SIEMENS |

| Weighing Controller | Switzerland / Mettler Toledo |

| PLC | Germany / SIEMENS |

| Electronic Components | Japan / Omron, France / Schneider |

| Load Cell | USA / Celtron |

| Phase Sequence Protection Relay | France / Schneider |

| Vacuum Pump | China / Rufus |

| Cylinder | Taiwan / Airtac, Japan / SMC |

| Linear Slides | Taiwan / Airtac |

| Miniature Geared Motors | TAIWAN / Wanxin, TAIWAN / Ruichuang |

| Servo Motor | Japan / Panasonic |

Ideal Application Scenarios

1

Grains

For the quantitative packaging of rice, millet, assorted cereals, beans, and pulses.

2

Nuts & Seeds

Perfect for peanuts, cashews, sunflower seeds, and various other agricultural seeds.

3

Pet Food

Provides clean, brick-shaped vacuum packaging for dry pet food to maintain freshness.

4

Other Materials

Suitable for various granular products, including animal feed and some chemical granules.

Advantages and Quality Commitment

Our Advantages

This machine leads the industry through Technological Leadership, Superior Quality components, exceptional Operational Efficiency requiring only a single operator, and a Comprehensive Service Guarantee from our expert technical team.

Quality Control & Production Process

Every machine undergoes our rigorous quality control system:

Raw Material Inspection: All incoming steel, parts, and electronic components must pass strict quality and specification inspections.

Precision Assembly: Experienced technicians assemble the machine following standardized procedures to ensure precision at every step.

System Commissioning & Testing: Each machine undergoes 72 hours of continuous, non-stop testing to simulate real-world production.

Final Pre-Shipment Inspection: Before dispatch, a final comprehensive inspection is conducted, accompanied by a detailed report.

Service Commitment & Support

Pre-Sales Consultation: Our expert team will help you find a tailored, optimal solution for your material and packaging needs.

Installation & Training: We offer professional on-site installation and commissioning services, along with comprehensive training.

After-Sales Support: We are committed to providing rapid-response service, whether remote guidance or spare parts supply.

Corporate Social Responsibility: We are dedicated to developing energy-efficient machinery that helps clients reduce power consumption.

Frequently Asked Questions (FAQ)

1. What bag sizes can this machine handle?

This machine is equipped with a replaceable bag support plate to accommodate a wide variety of bag sizes. Within the 0.3-5kg weighing range, we can customize and adapt the machine to your specific bag dimensions for brick-shaped packaging.

2. How long does it take to change over to a different product specification?

The changeover is very fast. Thanks to the quick-change mold design, a skilled operator can complete the transition of molds and parameters within 10-15 minutes, significantly enhancing production line flexibility.

3. Does this machine require highly skilled operators or a large team?

No. It features a user-friendly design with an intuitive interface (Siemens HMI). A single person can easily manage bag replenishment and machine supervision from a fixed station, greatly reducing labor intensity and costs.

4. What if our material has unique flow characteristics? Will it affect weighing accuracy?

Our feeding system combines gravity, vibration, and two-stage speed control to effectively handle granular materials with various flow properties. Before purchase, we welcome you to send us your material for testing to ensure the machine perfectly meets your accuracy requirements.