Heavy-Duty Fully Automatic Bagging System | 25-50kg

High-Speed Automatic Bag Filler for Industrial Packaging

This fully automatic bag filling machine is engineered for high-speed, unmanned packaging of various granular materials. As a complete, integrated system, it automates every step from bag placement and high-precision weighing to material filling and final stitched bag closure, dramatically increasing throughput for industrial-scale operations.

Capacity: 500 - 600 bags/hour

Weighing Range: 25kg - 50kg

Construction: Heavy-duty industrial steel frame

Diverse Application Scenarios

1

Agricultural & Food Industry

Ideal for the high-volume packaging of staple materials such as rice, grains, beans, sugar, salt, and various types of seeds for commercial distribution.

2

Animal Nutrition & Feed

Perfectly suited for the automated bagging of animal feeds, pelleted nutritional products, and bulk grains for the livestock and pet food industries.

3

Industrial Materials

Highly effective for bagging industrial granules like plastic resins, fertilizer pellets, road salt, and certain fine minerals.

4

Building & Construction

This system can also be configured as an automatic sandbag filler or for packaging other materials like fine gravel and aggregates.

Advanced System Advantages

Continuous, High-Throughput Operation

Engineered for maximum uptime, this system features a double-station bag-giving mechanism. Each station holds 100-300 bags, and when one runs low, an alarm alerts the operator to refill it while the machine seamlessly continues to draw from the other, enabling true non-stop production at speeds up to 600 bags per hour.

Intelligent and Stable Processing

The entire bag handling process—from picking and opening to clamping and filling—is monitored by air pressure detectors. If a bag is faulty, it is automatically ejected without stopping the line. Furthermore, the bag-clamping mechanism and the material discharge gate operate as two independent systems, ensuring maximum stability during filling. The mechanically linked conveyor system guarantees synchronized bag movement without slipping.

Servo-Driven for Effortless Adjustments

All major movements are powered by high-precision servo motors. This modern control architecture allows operators to easily adjust the system for different packing specifications via the Omron touch screen, eliminating the need for time-consuming and complex manual mechanical adjustments.

System Composition and Technical Parameters

| Parameter | Value |

| Packing Speed | 500 - 600 bags/hour |

| Package Weight Range | 25 - 50 kg |

| Accuracy | ± 0.2% |

| Applicable Bag Size (mm) | Length: 730-1100, Width: 330-650 |

| Bag Storage Capacity | 100 - 300 pcs per station |

| Air Pressure / Consumption | 0.5 - 0.6 MPa / Approx. 15 m³/h |

| Power Supply / Consumption | 3 Phase 380V/220V / 6KW |

| Overall Dimensions (L×W×H, mm) | 4430 × 3800 × 3750 |

Main Configuration: A Commitment to Quality

Our commitment to long-term reliability is reflected in our exclusive use of world-class components from leading international brands.

| Component Description | Brand / Origin |

| Touch Screen & PLC | Japan / Omron |

| Weighing Controller | Canada / General Measure |

| Load Cells | USA / Celtron |

| Power Switch & Intermediate Relay | Japan / Omron |

| Limit Switch | Japan / Omron |

| Circuit Breaker, Button, Knob | France / Schneider |

| Cylinder & Solenoid Valve | Taiwan / AirTac |

| Electric Cylinder | Japan / SMC, IAI |

| Servo Motor | China / Inovance |

| Vacuum Pump | Germany / Leybold |

| Stitching Machine | China / Bafang (Optional: Japan / Newlong) |

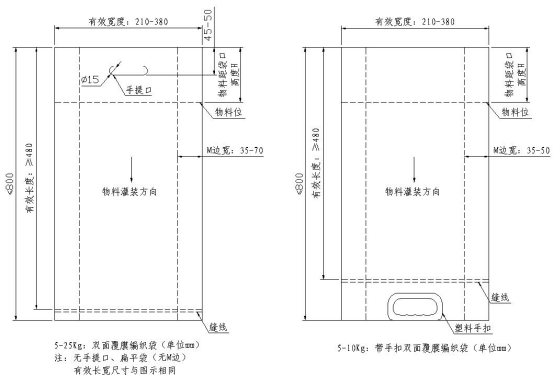

Bag Quality & Dimensional Specifications

To ensure maximum system speed and reliability, all bags must meet strict quality standards and be pre-approved by our technical team. Providing bag samples for testing is a mandatory step before order confirmation.

General Bag Quality Requirements:

Material must be double-sided laminated PP woven fabric.

The hardness of the front and back of the bag must be consistent.

Bags must be completely flat, with no bent corners. The bag mouth and any printed surfaces must not be sticky.

Bags must be stored flat in stacks of no more than 50 and shifted 100mm to relieve pressure at the opening.

Required Headspace After Filling (H): For reliable conveyance and stitching, sufficient empty space (headspace) is required at the top of the bag after filling.

For 25kg Bags: ≥230mm (no handle/fold) or ≥270mm (with handle and bag-top fold).

Our Partnership and Support

Quality Control and Assurance

Every auto bag filling machine is manufactured under strict quality control protocols. Each completed system undergoes comprehensive performance testing at our facility to verify its speed, accuracy, and durability before shipment. We are dedicated to delivering machinery that provides immediate and lasting value to your production process.

Frequently Asked Questions

1. Why is sending bag samples for testing required?

The reliability of a high-speed automatic bag filler is critically dependent on the consistency and quality of the bags. Testing allows our engineers to verify that your bags will feed, open, and clamp correctly at high speed and to make any necessary machine adjustments before delivery, guaranteeing optimal performance.

2. Can this system handle bags smaller than 25kg?

While this system is specifically designed and optimized for heavy-duty 25-50kg bags, other models in our range are available for smaller bag sizes. Please contact our sales team with your specific requirements.

3. What happens if there's a problem with a single bag during operation?

The machine's intelligent sensors will detect the anomaly (e.g., a bag that fails to open). It will automatically eject the faulty bag into a rejection bin and immediately proceed to pick the next one, all without requiring the entire line to be stopped.