High-Speed Fully Automatic Bulk Bagging Line for Grains & Granules

High-Speed Automated Packaging Solution

An advanced packaging line engineered for the high-speed bagging of bulk granular materials like buckwheat. It combines a double weighing mechanism with a fully automated conveying, labeling, and sewing system for unparalleled efficiency.

Application: Buckwheat, Grains, Feed, Granules

Capacity: 600 bags/hour

Packing Weight: 50kg

Product Highlights

High-Speed Dual Weighing

Equipped with a double feeding and weighing mechanism, this bag packing machine greatly increases output up to 600 bags/hour.

Fully Automated End-to-End

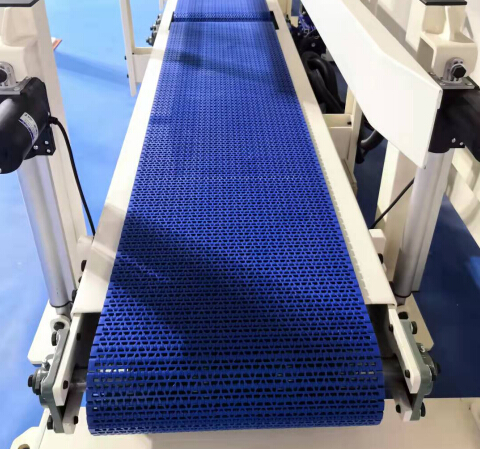

This packaging equipment automatically completes conveying, optional folding, labeling, and sewing, saving significant labor.

Intelligent Control & HMI

A large touch screen provides centralized control with convenient parameter setting and simple, user-friendly operation.

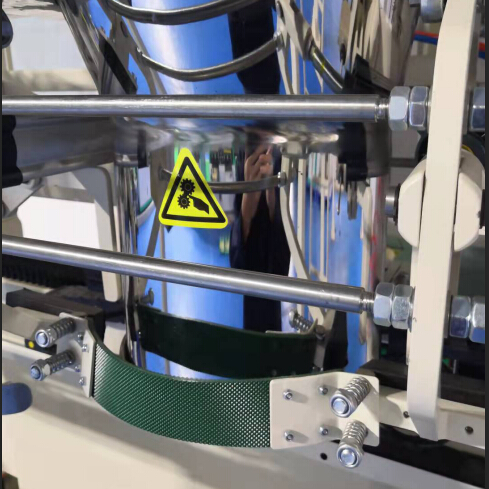

Versatile Dual-Feeding System

The combination of gravity and vibration feeding is especially suitable for mixed materials like half-powder, half-granule feed.

Technical Specifications

| Parameter | Value |

| Product Application | Buckwheat, grains, and other granular materials |

| Packing Weight | 50 kg |

| Production Capacity | 600 bags/hour |

| Measurement Accuracy | ±30g |

| Total Power | AC380V / 50Hz / 6KW |

| Compressed Air Consumption | 0.4 ~ 0.6 MPa, 4.5 m³/h |

| Bag Size (W x L) | W: 450-650mm, L: 550-1100mm |

| Label Size (W x L) | W: 65-105mm, L: 80-130mm |

| Material of Construction | Imported Stainless Steel (Contact Parts) |

Application Scenarios

1

Agriculture & Grain Industry

The primary application. Perfect for bulk packing of buckwheat, rice, seeds, lentils, soybeans, and corn.

2

Animal & Pet Feed Industry

Excellent for all types of animal feed, pet food (kibble), aquaculture feed, and other mixed nutritional feeds.

3

Chemical Industry

Well-suited for non-corrosive granular products such as plastic pellets, mineral salts, and bulk fertilizers.

4

High-Volume Production

Ideal for any facility that needs to pack a high volume of 50kg bags efficiently and with minimal labor.

Our Commitment & Frequently Asked Questions

Our Commitment to Quality

This bag packing machine and the entire packaging solution are built to the highest standards. We use high-quality imported components and food-grade stainless steel for all material contact surfaces. Our design prioritizes durability, hygiene, and user-friendliness to deliver a superior packaging equipment investment.

Q1: What makes this filling machine so much faster than other models?

A1: The key to its high speed is the innovative double feeding and weighing mechanism. By using two high-precision weighing systems that work in parallel, this machine can nearly double the output of a standard single-station bagger, allowing it to efficiently reach speeds of up to 600 bags per hour.

Q2: Can the packaging equipment handle dusty materials like animal feed?

A2: Absolutely. The machine's integrated gravity and vibration feeding system is specifically designed to handle a wide variety of materials, including challenging half-powder and half-granule mixtures common in the feed industry. To maintain a clean and safe workspace, the filling machine also includes a reserved interface for a dust collection device.

Q3: How much labor is required to operate this packaging line?

A3: One of the main benefits of this fully automated solution is the significant savings on labor costs. The entire line, from feeding to the final sewn bag, requires only one to two employees for supervision and the replenishment of packing materials like bags and labels.