LZB-1200-R40/S High-Speed Vacuum Packaging Machine

Premium Brick-Shaped Packaging for Barley, Sesame Seeds & Grains

A cutting-edge, high-speed solution for fine grains and granular materials. This machine combines a powerful quad-station architecture with intelligent weighing to deliver precise quantitative packaging.

Designed to elevate your product's presentation, extend shelf life, and significantly boost production throughput.

Model: LZB-1200-R40/S

Speed: 1000 - 1200 bags/hour

Key Feature: Intelligent Adaptive Weighing

Product Highlights

Exceptional Throughput

The quad-station architecture achieves remarkable speeds of 1000-1200 bags/hour, ideal for large-scale production.

Intelligent Adaptive Weighing

Automatically corrects parameters in real-time, adapting to various materials like barley and sesame seeds for X(0.5) accuracy.

Integrated Smart Control Hub

The entire process is centrally managed by a Siemens touch screen and Omron PLC for user-friendly operation.

Future-Proof & Easy to Maintain

Features a built-in fault self-diagnosis function and RS232/485 ports for easy integration and troubleshooting.

Technical Specifications

| Parameter | Details |

| Model | LZB-1200-R40/S |

| Weighing Extent | 0.35 - 5 kg |

| Speed | 1000 - 1200 bags/hour (based on rice) |

| Accuracy | X(0.5) |

| Power / Consumption | 4N-AC 380V 50Hz / 11KW |

| Air Requirements | 0.4-0.6MPa / 30m³/h (Customer-supplied) |

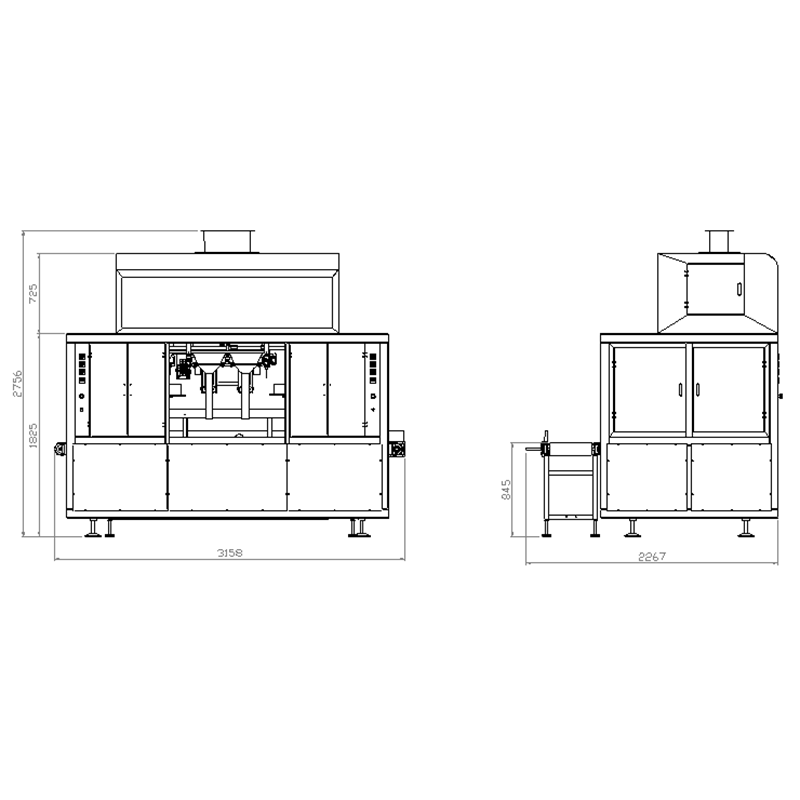

| Dimensions (L×W×H) | 3150 × 2350 × 2700 mm |

Core Component Configuration

| Name | Supplier |

| Touch Screen 10" | Germany / Simens |

| Weighing controller | SwitzerlandMettler Toledo |

| PLC | Japan / Omron |

| Switching Power Supply | Japan / Omron France / Schneider |

| Solid state relay | Japan / Omron |

| Intermediate relay | Japan / Omron |

| Load cell | USA/VPG |

| Phase sequence protection relay | France / Schneider |

| Vacuum pump | China/Zongde |

| Cylinder | Taiwan/Airtac Japan/SMC |

| Linear Slides | Taiwan/Airtac |

Ideal Application Scenarios

1

Fine Seeds & Grains

Specifically optimized for challenging materials like barley, sesame seeds, quinoa, and flaxseed.

2

Staple Grains

Provides high-speed quantitative packaging for rice, millet, various beans, and lentils.

3

Nuts & Pulses

Ensures gentle and efficient handling of peanuts, cashews, and other similar items.

4

Other Applications

Excellent for pet food, bird seed, and non-food granular products requiring secure packaging.

Our Advantages and Service Commitment

Our Core Advantages

Technological Superiority: The adaptive weighing algorithm ensures optimal speed and precision across all types of materials.

Unmatched Throughput: The quad-station design enables higher output to meet tight production schedules.

Reliability by Design: Premier components from global leaders guarantee superior stability and reduce downtime.

Operational Simplicity: An intuitive HMI combined with intelligent self-correction and diagnostics simplifies daily operations.

Quality Control & Production Process

Every machine is a testament to our commitment to quality. Our process includes Rigorous Component Inspection, Standardized Precision Assembly, Comprehensive System Testing, and a 48-Hour Full-Load Simulation before shipment to verify stability and reliability.

Service Commitment & Support

We offer Pre-Sales Consultation with material testing, professional on-site Installation & Training, and a lifetime After-Sales Guarantee with rapid-response service and a ready supply of spare parts to keep your production running.

Frequently Asked Questions (FAQ)

1. How does this machine handle materials as different as barley and fine sesame seeds?

The machine's strength lies in its intelligent adaptive weighing system. The control module automatically adjusts feeding to match the specific flow characteristics of each material, ensuring high accuracy for both coarse and fine granules.

2. What is the main reason for the machine's high speed of 1000-1200 bags/hour?

The speed is primarily achieved through its high-efficiency quad-station (four-station) architecture, which allows multiple stages of the packaging process to occur simultaneously, dramatically increasing overall throughput.

3. Is this machine difficult for a new operator to learn and use?

No. The large Siemens touch screen has an intuitive interface, and most parameter adjustments are automated. The fault self-diagnosis also provides clear instructions for easy troubleshooting.

4. Can this machine be integrated with our central factory control system?

Yes. It is equipped with standard RS232/485 communication ports, making it ready for integration with SCADA or other factory management systems for data logging and remote monitoring.