LZB-600-R10 Intelligent Vacuum Packaging Machine

Delivering Exquisite Brick-Shaped Packaging for Buckwheat, Oats & Specialty Grains

An advanced packaging solution engineered for high-value grains and granular materials. This machine integrates intelligent weighing with a top-tier German vacuum system to deliver precise, beautifully shaped packaging.

Designed to significantly enhance your product's shelf appeal and brand value.

Model: LZB-600-R10

Speed: 540 - 600 bags/hour

Key Component: German BECKER Vacuum Pump

Product Highlights

Intelligent Adaptive Weighing

New-generation system automatically adapts to material flow for consistent X(0.5) accuracy without manual adjustment.

Integrated Intelligent Control

Omron PLC and touch screen centralize control over the entire process, with real-time status tracking for simple operation.

Perfect Shaping & Superior Vacuum

A professional shaping mechanism and a German Becker vacuum pump ensure visually appealing packages and extended shelf life.

Future-Proof Scalability

Features fault self-diagnosis and reserved interfaces for automatic bag feeders and data communication (RS232/485).

Technical Specifications

| Parameter | Details |

| Model | LZB-600-R10 |

| Weighing Extent | 0.5 - 5 kg |

| Speed | 540 - 600 bags/hour |

| Scale Interval | 1 g |

| Accuracy | X(0.5) |

| Power/Consumption | 4N-AC 380V 50Hz / 4.5KW |

| Air Requirements | 0.4-0.6MPa / 6m³/h (Customer-supplied) |

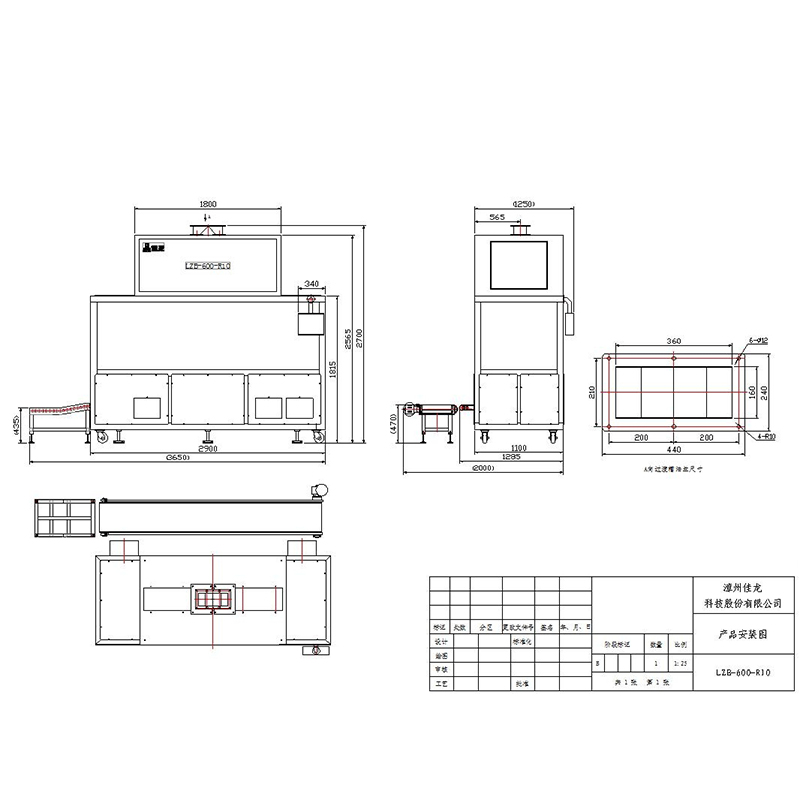

| Height | 2500 mm |

Core Component Configuration

| Name | Supplier |

| Touch Screen 10" | Japan / Omron |

| Weighing controller | Canada/General |

| PLC | Japan / Omron |

| Switching Power Supply | Japan / Omron |

| Solid state relay | Japan / Omron |

| Intermediate relay | Japan / Omron |

| Load cell | USA/VPG |

| Phase sequence protection relay | France / Schneider |

| Vacuum pump | Germany/ (BECKER) |

| Cylinder | Taiwan/Airtac |

| Solenoid valve | Taiwan/Airtac |

| Linear Slides | Taiwan/ABBA |

Application Scenarios

1

Specialty Grains

Perfect for high-value materials like buckwheat, oats, quinoa, and chia seeds.

2

Staple Grains

Ideal for quantitative packaging of rice, millet, beans, and corn grits.

3

Nuts & Seeds

Provides standardized vacuum packaging for peanuts, melon seeds, and crop seeds.

4

Other Food Industries

Excellent for pet food, nutritional powders, and other granular foods requiring preservation.

Our Core Advantages & Quality Commitment

Our Core Advantages

Technological Leadership: Advanced weighing algorithms ensure optimal speed and precision.

Exceptional Quality: Built with components from top-tier international suppliers like Omron and Becker.

Unmatched Stability: The original German-made Becker pump ensures continuous, stable production.

Future-Proof Investment: Designed for easy integration into future automation plans.

Quality Control & Production Process

Every machine must pass our stringent quality control process: Component Inspection, Standardized Assembly by experienced technicians, System Integration & Commissioning, and a rigorous 72-Hour Load Test before shipment.

Service Commitment & Support

We provide comprehensive support including Pre-Sales Service with free material testing, professional on-site Installation & Training, and 24/7 After-Sales Guarantee with remote diagnostics and spare parts supply.

Frequently Asked Questions (FAQ)

1. Besides buckwheat and oats, what other materials can this machine pack?

Absolutely. The adaptive weighing system provides excellent material compatibility, allowing it to precisely pack everything from conventional grains like rice to materials like peanuts and seeds.

2. What are the advantages of the German Becker vacuum pump?

Becker is a global leader known for high efficiency, low noise, long service life, and minimal maintenance. Using a Becker pump ensures your equipment has a stable and reliable "heart" for consistent, high-quality vacuum sealing.

3. How does the "fault self-diagnosis" feature work?

The Omron PLC system instantly detects any component issue and displays the specific fault location and cause on the touch screen, dramatically reducing downtime by allowing for quick and easy maintenance.

4. If we want to upgrade to a fully automatic line later, is this machine compatible?

Yes, perfectly compatible. It comes with a reserved "automatic bag feeder interface" and data communication ports (RS232/485) for seamless integration with other equipment.