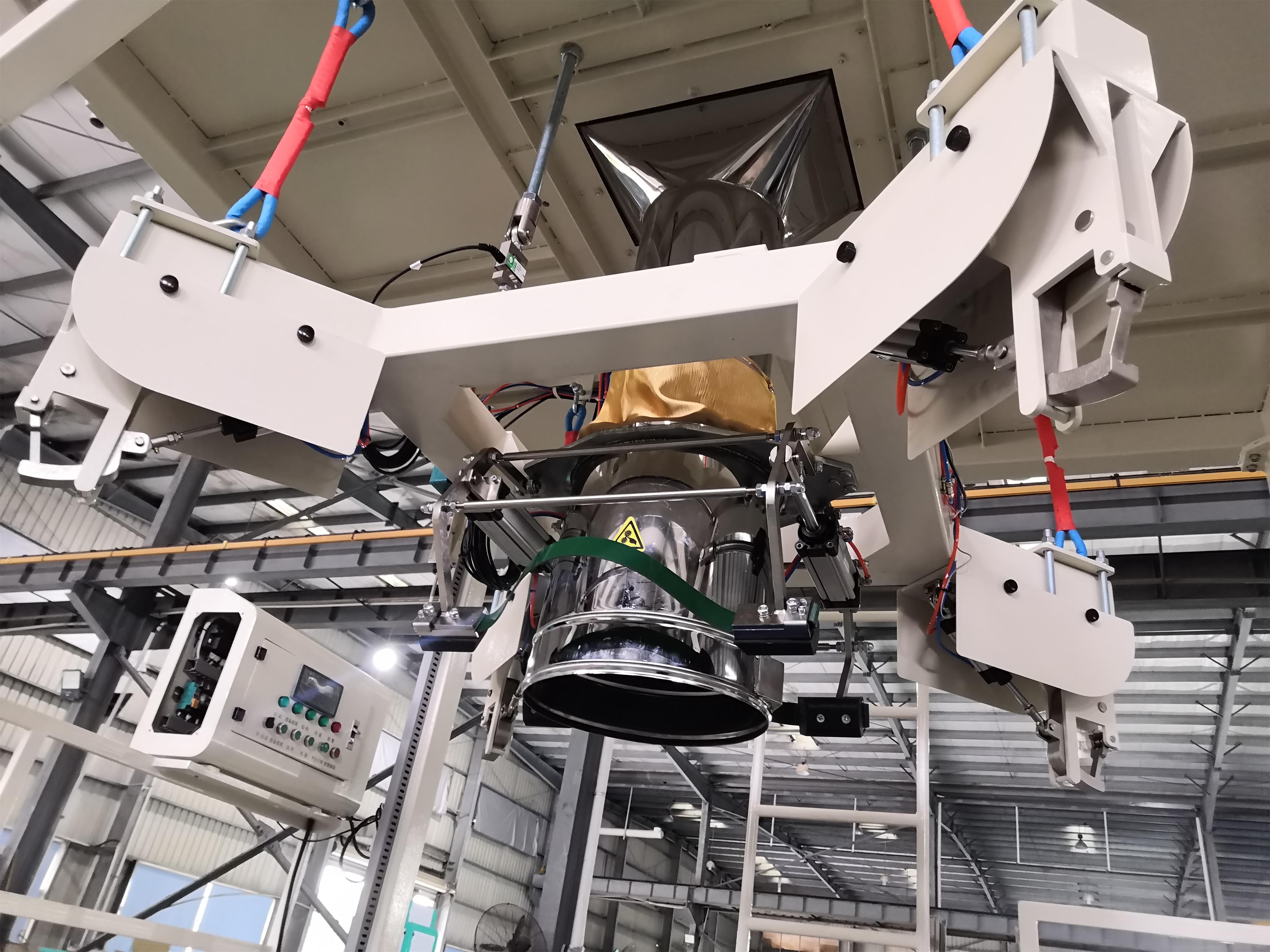

Heavy-Duty Bulk Bag Filling System for Industrial Applications - Model LCS-60T-CQ1

LCS-60T-CQ1 Bulk Bagging Equipment

A robust bulk bagging system for high-capacity (500-1000 kg) weighing and filling of FIBCs (big bags). It is engineered to streamline the packaging of granular materials, reduce labor, and prepare products for industrial transport.

Built for reliability with premium international components, it is the cornerstone of an efficient bulk material handling process.

Model: LCS-60T-CQ1

Weighing Capacity: 500 - 1000 kg

Packing Speed: 20 - 30 bags/hour

Product Highlights

Massive Weighing Capacity

Specifically designed to handle weights from 500 kg up to 1000 kg for filling FIBCs / big bags for B2B logistics.

High-Precision Bulk Filling

Achieves a high accuracy grade of X(0.2) with a premium Celtron (USA) load cell and General Measure controller.

Automated for Safety & Efficiency

Features fast gravity feeding and an automatic bag removal mechanism to reduce labor intensity and improve safety.

Industrial-Grade Reliability

Built with world-class components from Schneider, Omron, and Airtac to ensure stability in tough industrial environments.

Technical Specifications

| Model | LCS-60T-CQ1 |

| Weighing Range | 500 - 1000 kg |

| Packing Speed | 20 - 30 bags/hour |

| Accuracy Grade | X(0.2) |

| Power Consumption | AC 380V 50Hz 2.8KW (Customizable) |

| Air Consumption | 0.4 - 0.6 MPa, ~1 m³/h |

| Installation Height | Approx. 3800 mm |

Main Configuration

| Name | Brand |

|---|---|

| Weighing Controller | General Measure (Canada) |

| Load Cell | Celtron (USA) |

| Switches (Power, Limit) | Omron (Japan) |

| Breakers, Relays, Buttons | Schneider (France) |

| Pneumatic System (Cylinder, Solenoid Valve) | Airtac (Taiwan) |

Application Scenarios

1

Agriculture & Grain Handling

Bulk loading of rice, wheat, corn, soybeans, and seeds from silos into big bags for transport or storage.

2

Industrial & Chemical Production

Packaging bulk materials like plastic resins (pellets), fertilizers, and non-corrosive chemical powders.

3

Mining, Minerals & Construction

Perfectly suited for bagging sand, gravel, cement, salt, and other bulk mineral products accurately.

4

Large-Scale Food Processing

Used for B2B packaging of bulk sugar, salt, starches, and other granular ingredients shipped between facilities.

Detailed Information

Our Commitment to Quality

Heavy-Duty Fabrication: The frame is built from heavy-gauge structural steel to withstand multi-ton loads in a 24/7 production environment. Product contact parts are stainless steel.

Premium Component Integration: We source electrical and pneumatic components directly from global leaders like Schneider and Omron to guarantee performance.

Load & System Testing: Every machine undergoes a full system test with calibrated weights simulating 1000 kg loads to ensure structural integrity and accuracy.

Final Safety Audit: A senior engineer performs a final audit, verifying all safety interlocks, pneumatic functions, and controller settings before shipment.

Frequently Asked Questions (FAQ)

1. What types of big bags (FIBCs) can this machine handle?

It is designed for standard 4-loop FIBCs. The filling spout diameter can be customized to match your specific bag inlet dimensions.

2. How is dust managed during the filling process?

The system features a sealing mechanism on the filling head. It is also equipped with a dust collection port, allowing you to connect it to your facility’s dust extraction system for a clean environment.

3. What foundation is required for installation?

The machine requires a solid, level concrete floor capable of supporting the machine's weight plus the maximum 1000 kg filled bag weight. The installation height is approximately 3.8 meters.

4. Can this machine handle powders?

This model uses a gravity feeder, which is best for free-flowing granular materials. For non-free-flowing powders, we offer alternative models with screw feeders. Please consult our experts for the perfect solution for your material.