LCS-150T High-Capacity Bulk Grains Scale

LCS-150T Industrial Grain Filling & Weighing System

Engineered for high-volume industrial sectors, the LCS-150T Bulk Grains Scale provides unparalleled accuracy and throughput for grain processing facilities, chemical plants, and port logistics. This system is the definitive solution for precise, automated bulk material handling.

Featuring a fully enclosed, dust-proof design and robust construction, this grain filling scale ensures reliable, continuous operation in the most demanding environments, with a remarkable capacity of up to 150 tons per hour.

Model: LCS-150T

Capacity: Up to 150 Tons/Hour

Core Technology: Cumulative Batch Weighing

Key Advantages

Massive Throughput

Capable of accurately weighing and processing up to 150 tons of granular material per hour, making it ideal for the most demanding bulk handling and transfer applications.

Dust-Proof Industrial Design

Features a fully enclosed structure and a sealed electrical control box, protecting internal components from dust and ensuring clean, safe, and reliable operation.

Durable & Reliable Construction

The feeding and measurement systems are constructed from imported, high-wear-resistance stainless steel, guaranteeing a long service life and sustained weighing accuracy.

Smart Data Integration

Equipped with an RS232/485 serial port for seamless communication with central factory management systems and an optional printer for on-site production reports.

Technical Specifications

| Parameter | Model: LCS-150T |

| Throughput Capacity | 150 Tons/Hour |

| Accuracy Grade | Class X(0.2) |

| Power Supply & Consumption | AC 220V, 50Hz, 70W |

| Air Supply & Consumption | 0.4~0.6 MPa, 1 m³/h |

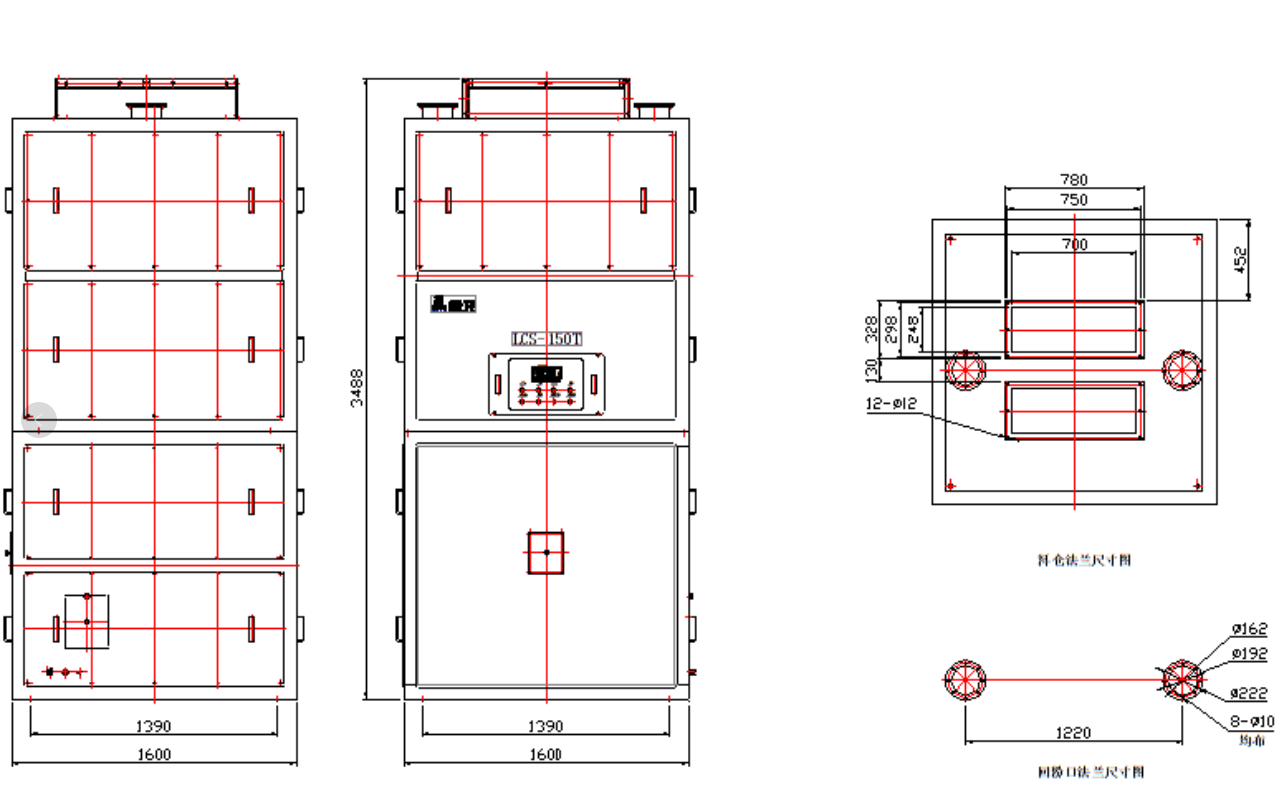

| Installation Height | 3500 mm |

Main Component Configuration

| Component | Brand / Supplier |

| Weighing Controller | China/Zhiyuanda |

| Power Switch | Taiwan/Meanwell |

| Low-Voltage Electricals (Button, Knob) | France/Schneider |

| Load Cell | China/ZEMIC |

| Pneumatic Elements (Cylinder, Solenoid Valve) | Taiwan/Airtac |

Application Scenarios

1

Port Logistics & Terminals

The ultimate bulk grains scale for high-speed loading and unloading of ships, trains, and trucks, ensuring accurate weight measurement for trade and transport.

2

Grain Silo Management

Use as a high-precision grain filling scale for accurate intake, outtake, and internal transfer of materials between large storage silos.

3

Large-Scale Food Processing

Accurately dose large quantities of raw granular materials like grain, rice, or sugar into a continuous processing or mixing line.

4

Chemical & Mineral Industries

Efficiently weigh and handle high volumes of granular chemicals, fertilizers, or minerals with a robust, dust-proof system designed for harsh industrial use.

In-Depth Details

Operational Principle

The LCS-150T operates as a high-speed cumulative batching scale. Material flows into an upper buffer silo and then into the weighing hopper. When the weighing hopper is full, the inlet gate closes, and the system records the precise weight. The discharge gate then opens, releasing the material. This cycle repeats continuously. The intelligent controller automatically sums the weight of each individual batch to provide a highly accurate total accumulated weight of all material that has passed through the scale.

Our Commitment to Quality and Sustainability

Engineered for reliability in harsh industrial environments, the LCS-150T features a robust, fully enclosed, and dust-proof design. The main body and key internal components are crafted from wear-resistant stainless steel to ensure a long operational lifespan and prevent contamination. Our commitment to sustainability is reflected in its extremely low power consumption (70W), which reduces operating costs and minimizes environmental impact. Every unit undergoes rigorous factory testing and calibration to guarantee performance and accuracy.

Comprehensive Service & Technical Support

Process Integration Consulting: Our technical experts will evaluate your facility's layout and process flow to ensure seamless integration of the bulk grains scale into your existing material handling system.

Installation and Commissioning Support: We provide detailed manuals, diagrams, and remote engineering assistance to guide your team through the installation and commissioning process for a smooth startup.

Lifetime Technical Assistance: We stand behind our products with lifetime support. Our expert team is always available to help with operational questions, troubleshooting, and optimization.

Frequently Asked Questions (FAQ)

Q1: What is the main purpose of this scale? Is it for bagging?

A: This is not a bagging scale. It is a bulk weighing scale used to measure the total weight of a large quantity of material being transferred from one point to another, such as from a silo to a truck, or into a processing line. It provides a highly accurate "totalized" weight.

Q2: How does the system handle a very dusty environment like a grain elevator?

A: The system is specifically designed for such conditions. Its main body is fully enclosed, and the electrical control box is completely sealed. This prevents dust from entering and affecting the sensitive weighing components and electronics, ensuring reliable operation.

Q3: How do I get production data from the scale?

A: The scale's controller is equipped with a standard RS232/485 serial communication port. This allows you to connect it to a plant-level PLC or SCADA system to automatically record data. Additionally, an optional printer can be configured to print batch reports and production summaries directly at the machine.