LZB-150-M3/S Automatic Granule Vacuum Packing Machine for Brick-Shaped Packaging

LZB-150-M3/S Automatic Granule Vacuum Packing Machine

An advanced, fully automatic packaging solution engineered for creating perfect, brick-shaped vacuum-sealed packages. The LZB-150-M3/S is designed for high-speed, quantitative packaging of granular products, ensuring product integrity, extending shelf life, and delivering a premium, uniform appearance for your goods.

Model: LZB-150-M3/S

Capacity: 140-160 bags/hour

Material: Food-contact parts are made of high-quality stainless steel for hygiene and durability.

Product Highlights

Precision Dual-Feeding System

Integrates gravity and vibration feeding to handle delicate materials gently, maintain particle integrity, and guarantee stable performance.

Intelligent User-Friendly Control

Managed by an OMRON PLC and Touch Screen for intuitive control over the entire process, with real-time status tracking.

Cost-Effective Packaging

Uses innovative two-sided gusseted bags to create a six-sided brick shape, significantly reducing material costs.

Seamless Production Line Integration

Designed with a right-side discharge conveyor that enables seamless docking with subsequent downstream equipment.

Technical Specifications

| Parameter | Value |

| Model | LZB-150-M3/S |

| Weighing Range | 25 ~ 50 lbs (approx. 11.34 ~ 22.68 kg) |

| Operational Speed | 140-160 bags/hour |

| Accuracy Grade | X(0.5) |

| Power & Consumption | AC 380V 50Hz, 5KW |

| Required Air Pressure | 0.4 ~ 0.6 MPa |

| Air Consumption | 20 m³/h |

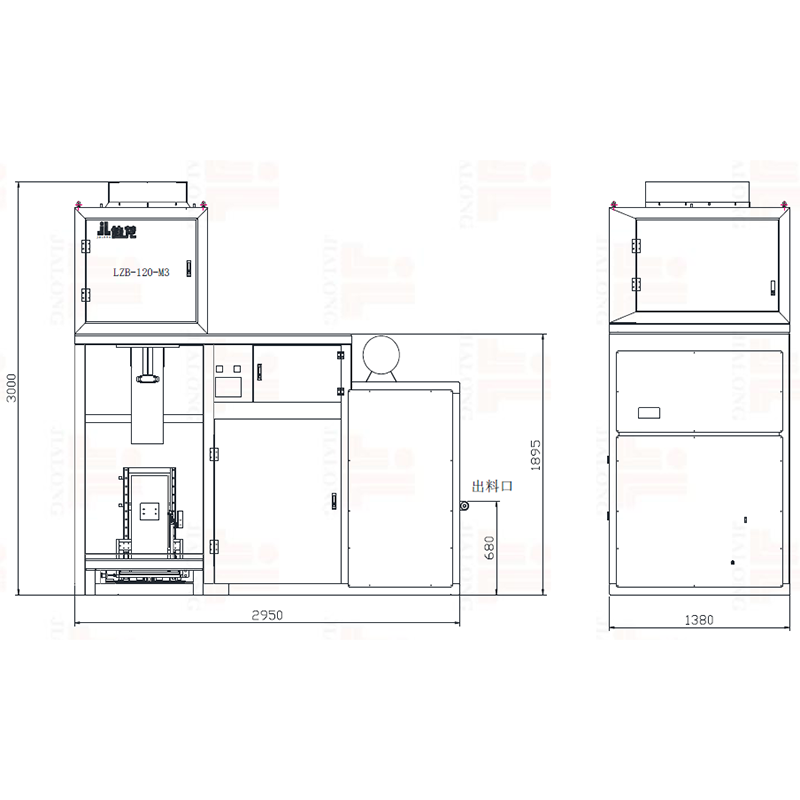

| Machine Dimensions (L × W × H) | 2950 × 1380 × 3000 mm |

| Appearance & Colors | Industrial-grade stainless steel silver with green frame accents. |

| Primary Materials | Food-contact parts made of stainless steel; frame made of heavy-duty carbon steel. |

| Certifications | Components conform to international standards (CE, etc.). |

Application Scenarios

1

Food Industry

Perfect for packing cashew nuts, peanuts, almonds, rice, whole grains, lentils, beans, coffee beans, and sugar.

2

Pet Food Industry

Excellent for high-end cat litter, premium dry dog food, and bird seed, providing an airtight seal that preserves freshness.

3

Chemical & Agricultural Sector

Suitable for seeds, non-corrosive granular fertilizers, and plastic pellets.

4

High-Value Granules

Ideal for any granular product where appearance, freshness, and package integrity are top priorities.

Technical Advantage & Quality Control

Our commitment to excellence is reflected in our rigorous design, manufacturing process, and component selection.

Production & Quality Assurance Process

Each LZB-150-M3/S machine undergoes a meticulous manufacturing and quality control process. This includes precision fabrication of the machine frame, careful assembly of all electronic and pneumatic components, and a multi-stage testing protocol. Before shipment, every unit is subjected to comprehensive calibration, a 24-hour continuous operational stress test, and a final quality inspection to ensure it meets our high standards for performance and reliability.

Premium Component Sourcing

We build our machines with globally recognized, high-quality components to ensure stability, longevity, and superior performance.

| NO. | Component | Supplier | Origin |

| 1 | Touch Screen | OMRON | Japan |

| 2 | Weighing Controller | General Measure | Canada |

| 3 | PLC | OMRON | Japan |

| 4 | Power Supply | OMRON | Japan |

| 5 | Solid State Relay | OMRON | Japan |

| 6 | Intermediate Relay | OMRON | Japan |

| 7 | Load Cell | Zemic | China |

| 8 | Phase Order Protector | Schneider | France |

| 9 | Vacuum Pump | Raffles | Jiangsu |

| 10 | Cylinder | AirTAC | Taiwan |

| 11 | Solenoid Valve | AirTAC | Taiwan |

| 12 | Linear Guide | ABBA | Taiwan |

| 13 | Reduction Drive | Taibang | China |

| 14 | Servo Motor | Huichuan | Shenzhen |

Our Company Advantages

Expert Engineering: Our team consists of experienced engineers dedicated to continuous innovation in packaging technology.

Customization Capabilities: We can work with you to tailor machine specifications and configurations to meet your unique product and production needs.

Global Reach: We have a network to support clients worldwide, ensuring you receive the assistance you need, wherever you are.

Pre-Sales & After-Sales Service

Pre-Sales Service

Consultation: In-depth discussion to understand your needs and recommend the best solution.

Material Testing: We can test-pack your product samples to demonstrate the machine's performance and quality.

Layout Planning: Assistance in planning how the machine will integrate into your existing facility.

After-Sales Service

Installation & Training: On-site or remote support for machine installation, commissioning, and operator training.

Technical Support: A dedicated technical team is available via phone, email, and video call to troubleshoot any issues promptly.

Spare Parts: A ready supply of all essential spare parts to minimize any potential downtime.

Corporate Social Responsibility

We are committed to sustainable and responsible manufacturing. The LZB-150-M3/S is designed with an energy-efficient servo motor and vacuum system to reduce power consumption. By enabling more compact, waste-reducing packaging, we help our clients minimize their environmental footprint.

Frequently Asked Questions (FAQ)

Q1: What is the primary benefit of the six-sided, brick-shaped package?

A1: The brick-shaped package offers superior stability for palletizing and shelving, an enhanced premium appearance, and an airtight seal that maximizes product freshness and shelf life.

Q2: Is the machine difficult to operate for new staff?

A2: No. It is equipped with an intuitive OMRON touch screen interface that is easy to learn. We also provide comprehensive training during installation to ensure your team is fully confident in operating the machine.

Q3: Can the machine handle different bag sizes and product weights?

A3: Yes. The machine is designed for flexibility. Different bag sizes can be accommodated by a simple and quick mold changeover process. The weighing system is easily adjustable within its specified range of 25 to 50 lbs.

Q4: How do you ensure the weighing is accurate?

A4: The machine uses a high-precision load cell from Zemic and an advanced weighing controller from General Measure, combined with a precise bucket measuring system. This configuration achieves an accuracy grade of X(0.5), minimizing product giveaway.