LZB-500-FR10 Dual-Mode Automatic Vacuum Packaging Machine for Granular Products

LZB-500-FR10 Dual-Mode Granular Vacuum Packer

An exceptionally robust and versatile automatic packaging solution, precision-engineered for the high-speed vacuum sealing of granular products. Features a world-class German-made vacuum pump for superior product preservation.

Model: LZB-500-FR10

Capacity: Cubic: 300-360; Flatten: 180-240 bags/hr

Material: Food-grade stainless steel contact parts

Product Highlights

World-Class German Vacuum Tech

Features a high-performance LEYBOLD vacuum pump from Germany for a faster, deeper, and more reliable vacuum.

Dual-Function Versatility

Masterfully designed to produce both cubic (brick-shaped) and flat-shaped vacuum packages on a single machine.

Wide & Flexible Packaging Range

Expertly handles a broad spectrum of weights, with cubic mode for 0.5-5kg and flatten mode for 1-10kg.

Precision Global Components

Built with recognized leaders like Omron (Japan), Celtron (USA), and Schneider (France) for dependable performance.

Technical Specifications

| Parameter | Value |

| Model | LZB-500-FR10 |

| Weighing Range | Cubic: 0.5 ~ 5 kg Flatten: 1 ~ 10 kg |

| Operational Speed | Cubic Shape: 300 ~ 360 bags/hour Flatten Shape: 180 ~ 240 bags/hour |

| Scale Interval | 2 g |

| Accuracy Grade | X(0.5) |

| Power & Consumption | 4N-AC 380V 50Hz, 4.0KW |

| Required Air Pressure | 0.4 - 0.6 MPa |

| Air Consumption | 22 m³/h |

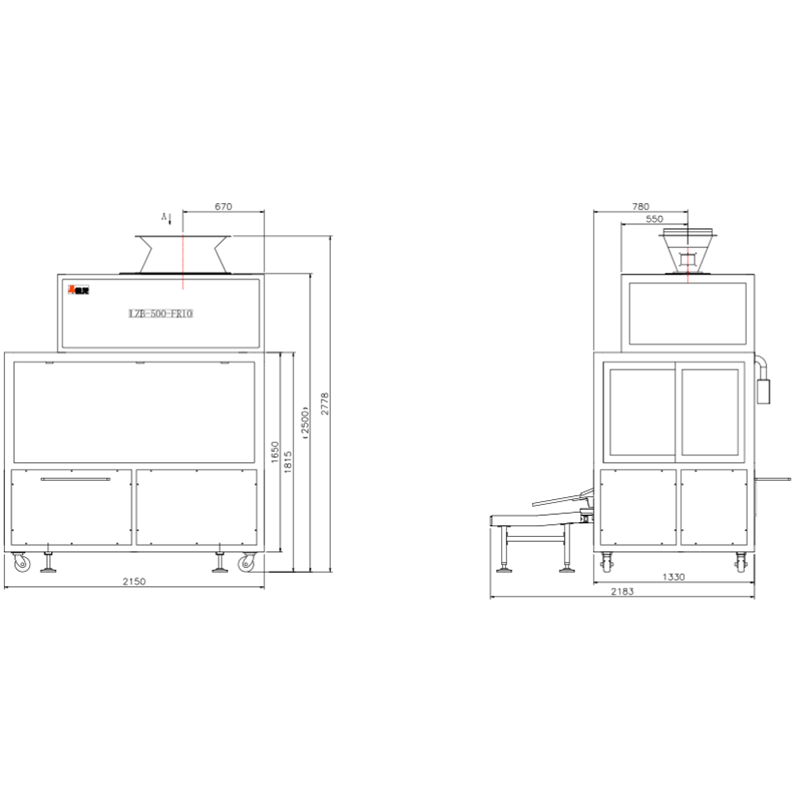

| Machine Dimensions (L×W×H) | 2150 × 2200 × 2800 mm |

| Primary Materials | High-quality, food-grade stainless steel contact parts; robust carbon steel frame. |

Note: Stated operational speed and performance are based on a design volume standard of rice with a bulk density of 0.8 kg/L.

Application Scenarios

1

Coffee & Food Industry

Perfectly suited for whole bean coffee, roasted nuts, groundnuts (peanuts), rice, seeds, lentils, and sugar.

2

Pet Care Industry

The premier choice for packaging premium cat litter (tofu, clay, silica gel) and dry pet food into compact bricks.

3

Chemical & Other Industries

Effective for packing non-corrosive materials like specialty sands, plastic resins, and other bulk items.

4

High-Value Goods

Ideal for any product where maximum freshness, aroma preservation, and package appearance are critical.

Technical Advantage & Quality Control

Production & Quality Assurance Process

Every LZB-500-FR10 unit is constructed under a strict quality management system. The process involves the precision fabrication of the structural frame, followed by the expert assembly and wiring of all systems by our skilled technicians. Prior to dispatch, each machine undergoes a rigorous final inspection, including a comprehensive system calibration, a 24-hour continuous operational stress test, and a vacuum-level performance check to ensure it meets our highest standards of quality and reliability.

Premium Component Sourcing

| No | Component | Supplier | Origin |

| 1 | Touch Screen | WEINVIEW | Shenzhen |

| 2 | Weighing Controller | General Measure | Canada |

| 3 | PLC | Omron | Japan |

| 4 | Power Supply | Omron | Japan |

| 5 | Solid State Relay | Omron | Japan |

| 6 | Intermediate Relay | Omron | Japan |

| 7 | Load Cell | Celtron | USA |

| 8 | Phase Order Protector | Schneider | France |

| 9 | Vacuum Pump | LEYBOLD | Germany |

| 10 | Cylinder | Airtac | Taiwan |

| 11 | Solenoid Valve | Airtac | Taiwan |

Our Company Advantages

Engineering Excellence: Our team is dedicated to innovating packaging technology, ensuring our clients receive machines that are both powerful and user-friendly.

Customized Solutions: We collaborate with our clients to tailor machine configurations that precisely match their product, packaging material, and factory layout needs.

Dedicated Global Support: We have an established network to support clients worldwide, providing expert assistance from initial consultation through long-term operation.

Pre-Sales & After-Sales Service

Our commitment to our clients ensures a partnership for the entire lifecycle of your machine.

Pre-Sales Service: Includes in-depth consultation, product sample testing, and facility layout assistance.

After-Sales Service: Includes professional installation & training, prompt technical support, and spare parts availability.

Frequently Asked Questions (FAQ)

Q1: Why is the German-made LEYBOLD vacuum pump a major advantage?

A1: LEYBOLD is a global leader in vacuum technology. Their pumps are renowned for creating a deeper vacuum faster and maintaining it with exceptional reliability. For products like coffee, this means better preservation of volatile aromas and oils. For all products, it means a tighter, more professional-looking package and a longer-lasting machine.

Q2: Can this machine handle products other than coffee beans and cat litter?

A2: Yes, absolutely. The machine is designed for a wide range of free-flowing granular products. It is ideal for nuts, seeds, grains, rice, beans, and similar items. It is not, however, designed for fine powders, liquids, or sticky products.

Q3: How difficult is it to switch between producing flat packages and brick-shaped packages?

A3: The switch-over is designed to be user-friendly. It involves a straightforward mechanical adjustment of the forming mold and selecting the new recipe on the HMI touch screen. A trained operator can typically complete the changeover efficiently.

Q4: What kind of weighing accuracy can I expect?

A4: The machine is equipped with a high-precision load cell from Celtron (USA) and a sophisticated weighing controller from General Measure (Canada), achieving an accuracy grade of X(0.5). This ensures minimal product giveaway and consistent package weights.