DCS-50(V15) Automatic Packaging Machine for Bran & Bulk Materials

DCS-50(V15) Automated Packaging System for Bulk & Low-Density Materials

Master the challenge of packaging difficult, low-density materials with the DCS-50(V15). This fully automatic industrial packaging system is expertly engineered to handle products like coarse and fine bran with exceptional efficiency and precision.

From automatic bag sorting and conveying to folding, sewing, and thread trimming, this turnkey solution streamlines your entire workflow. Its intelligent controls and robust design make it the definitive choice for high-volume commercial packaging operations.

Model: DCS-50(V15)

Weighing Range: 25 - 50 kg

Core Feature: End-to-End Automation

Key Advantages

Complete Automation

Automates the entire workflow from bag sorting, conveying, weighing, and filling to folding and sewing, significantly reducing labor costs and manual handling.

Superior On-Site Adaptability

This commercial bagging system is compatible with a wide range of bag materials and features a compact installation footprint, making it easy to integrate into existing production facilities.

Intelligent & User-Friendly

A large Omron touchscreen provides centralized control for convenient parameter setting, while the system offers real-time status tracking and intuitive alarm prompts.

Robust Conveying System

Utilizes a strong and durable chain plate conveyor belt that resists deviation and includes an automatic lifting function to accommodate different bag heights.

Technical Specifications

| Parameter | Model: DCS-50(V15) |

| Weighing Range | 25 - 50 kg |

| Packaging Speed | 300 - 400 bags/hour (dependent on material & bagging speed) |

| Weighing Accuracy | Class X(0.2) |

| Compatible Bag Dimensions | Width: 600-700mm; Length: 700-1100mm |

| Power Requirement | 380V / 50Hz / 3-Phase, 4.0 kW |

| Air Requirement | 0.5~0.6 MPa, 6 m³/hour |

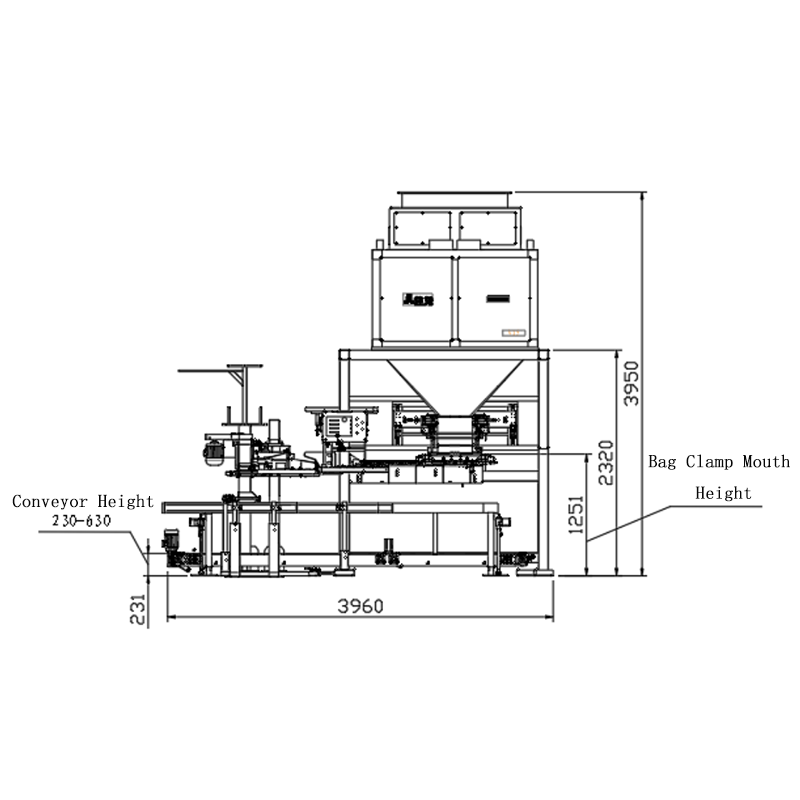

| Overall Dimensions (L×W×H) | 4000 mm × 1360 mm × 3950 mm |

Main Component Configuration

| Component | Brand | Origin |

| PLC & Touch Screen | OMRON | Japan |

| Servo Motor | Inovance | China |

| Frequency Converter & Relay | Panasonic & Siemens | Japan & Germany |

| Weighing Controller & Sensor | Walton & Celtron | China & USA |

| Low-Voltage Electricals | Schneider | France |

| Pneumatic Components | SMC / AirTAC | Japan / Taiwan |

Application Scenarios

1

Animal Feed & Byproducts

The definitive solution for bran bagging equipment. Its specialized feeding system ensures that light, low-density materials like coarse and fine bran are packaged efficiently and without issue, making it vital for feed mills.

2

Grain Processing & Milling

Ideal for various commercial packaging systems, this equipment provides high-speed, automated packaging for grains, seeds, and other granulated food products, from intake to a fully sealed bag.

3

Chemical & Fertilizer Production

This industrial bagging system is robust enough for the chemical sector, reliably packaging granular fertilizers and other non-corrosive industrial powders and materials into large-format bags.

4

High-Volume Production Lines

Designed for factories that require end-to-end automation, this system reduces labor dependency, increases throughput, and ensures a high degree of packaging consistency, justifying its role in modern commercial packaging.

In-Depth Details

Operational Workflow

This industrial bagging system offers a complete "hands-free" workflow. The cycle begins as the machine automatically sorts and presents a single empty bag to the filling station. After precise weighing, the material is cleanly discharged. The bag is then seamlessly transferred by the robust chain-plate conveyor, which can automatically adjust its height, to the integrated sewing station. The sewing head performs a secure stitch closure with automatic thread trimming, producing a professionally packaged, shelf-ready product.

Our Commitment to Quality and Corporate Responsibility

We build our commercial packaging systems to the highest standards of engineering and durability. This machine features a heavy-duty framework and relies on an array of premium components from world-leading brands to ensure long-term stability and reliability. In line with our corporate responsibility, we have engineered this system to be highly energy-efficient, minimizing the operational footprint of our clients. By automating laborious tasks, we also contribute to a safer and more ergonomic work environment.

Comprehensive Service and Technical Support

Expert Consultation & Integration: Our technical team will provide an in-depth consultation to assess your site and material handling needs, ensuring the DCS-50(V15) is configured for optimal integration and performance.

Full Technical Assistance & Training: We supply comprehensive documentation and training resources. Our engineers are available for remote support to guide your team through installation, commissioning, and operation.

Guaranteed Spare Parts: We maintain a complete stock of all essential components for our bran bagging equipment and other systems, guaranteeing fast dispatch to minimize any potential downtime.

Frequently Asked Questions (FAQ)

Q1: What makes this machine particularly effective for packaging bran?

A: Bran is a very light, low-density material that does not flow easily and can bridge or clog in standard feeders. This machine uses a specialized vibration feeding system combined with gravity, ensuring that light materials like bran are fed consistently and smoothly into the weigh hopper for accurate measurement without interruption.

Q2: Is this a fully automatic system? What manual intervention is required?

A: Yes, this is a fully automatic industrial packaging system. It performs all functions from bag sorting to final sewing without operator intervention. The only manual task is to periodically load a new stack of empty bags into the bag magazine.

Q3: Can this system handle different types of bags, like paper and gusseted bags?

A: Absolutely. The machine is designed for high adaptability. It can handle a variety of open-mouth bags, including paper and PP woven bags. It also features a setting for manually adjusting gusseted bags to ensure they are properly positioned and filled, giving you excellent flexibility.