High-Speed Dual-Hopper Packaging Machine for Nuts & Granular Products - Model DCS-5-V2

DCS-5-V2 Dry Fruit & Hickory Nuts Packing Machine

A high-performance packaging machine engineered for the fast and gentle handling of granular products. Featuring a dual-hopper design and a sophisticated vibratory feeding system, it's the perfect solution for delicate materials like nuts and seeds.

This machine delivers exceptional speed (up to 660 bags/hour) and accuracy, all while protecting the integrity of your valuable product.

Model: DCS-5-V2 (Dual Hopper)

Peak Throughput: 540 - 660 bags/hour

Weighing Range: 0.5 - 5 kg

Product Highlights

High-Speed Dual-Hopper System

Two large 28L weighing hoppers work in parallel to dramatically increase throughput for large-scale production.

Gentle Vibratory Feeding

An advanced vibratory system ensures a fast yet gentle flow, minimizing impact and damage to fragile products like nuts.

Precision Weighing

Utilizes a high-sensitivity Celtron (USA) load cell to deliver consistent and reliable weighing accuracy.

Industrial Reliability

Control and pneumatic systems are built with world-class components from Schneider and Airtac for maximum durability.

Technical Specifications

| Model | DCS-5-V2 (Dual Hopper) |

| Weighing Range | 0.5 - 5 kg |

| Speed | 540 - 660 bags/hour |

| Accuracy Grade | X(0.5) |

| Weighing Hopper Capacity | 28 L × 2 |

| Power Supply | 4N-AC 220V 50Hz 0.8KW (Customizable) |

| Air Supply | 0.4 - 0.6 MPa, ~1 m³/h |

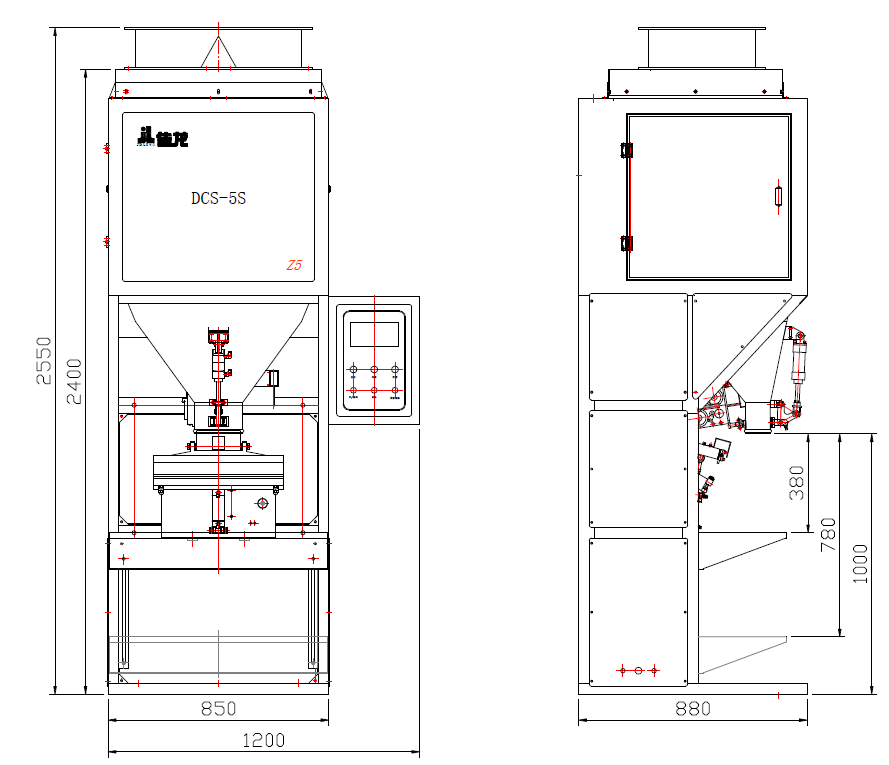

| Dimensions (L×W×H) | 2660 × 1100 × 1150 mm |

Main Configuration

| Item | Brand |

|---|---|

| Weighing Controller | Zhiyuada |

| Switching Power Supply | Omron (Japan) |

| Button / Knob | Schneider (France) |

| Load Cell | Celtron (USA) |

| Pneumatic Elements (Cylinder, Solenoid Valve) | Airtac (Taiwan) |

Application Scenarios

1

Snack Food Industry

Packaging all types of nuts (walnuts, hickory), seeds (sunflower, pumpkin), trail mix, and dried fruit.

2

Confectionery & Sweets

Accurately bagging hard candies, chocolate drops, gummy bears, and other items without causing damage.

3

Agriculture & Horticulture

Efficiently packages high-value seeds, specialty grains, and other granular agricultural products.

4

Hardware & Small Parts

Versatile enough for weighing and packaging small items like screws, bolts, and plastic fittings.

Detailed Information

Our Quality & Manufacturing Commitment

Component Vetting: We source critical components directly from global leaders like Schneider, Omron, and Celtron, ensuring reliability and performance.

Precision Calibration: Our technicians are specially trained in calibrating vibratory weighing systems. Each load cell is meticulously calibrated for accuracy from the first bag to the last.

48-Hour Endurance Test: Every machine undergoes a continuous 48-hour run test with sample materials to ensure flawless, stable performance under real-world conditions.

Final Audit: Before shipment, a final inspection is conducted by senior engineers to verify all functions, safety mechanisms, and calibration settings.

Frequently Asked Questions (FAQ)

1. Why is vibratory feeding better for nuts and seeds?

Vibratory feeding is extremely gentle. It moves the product using high-frequency vibrations, which prevents the cracking, chipping, or breakage that can be caused by other methods.

2. Can this machine handle mixed products like trail mix?

Yes, the system is excellent for free-flowing mixes. The vibratory feeder provides a consistent flow even with items of varying size and density.

3. How easy is it to clean for product changeovers?

The machine is designed with accessibility in mind. The product contact parts are typically made of food-grade stainless steel, which allows for quick and easy cleaning.

4. What does accuracy grade "X(0.5)" mean?

This is a formal accuracy classification that indicates a high level of precision suitable for commercial and retail packaging, ensuring you minimize product giveaway and meet label weight requirements.