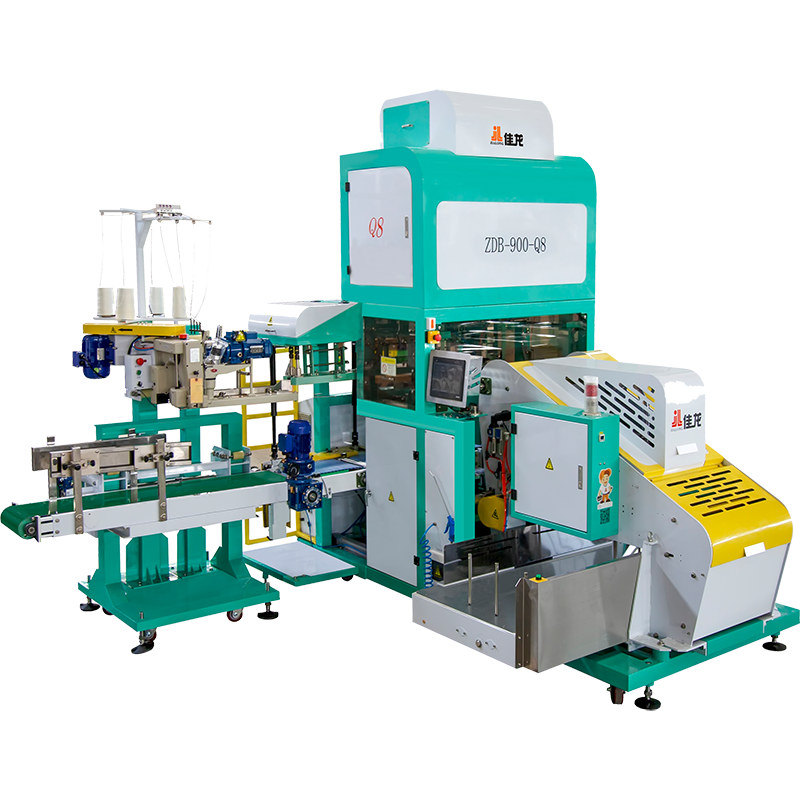

Fully Automatic Bagging Machine for Granular Materials - Model ZDB-900-Q8

High-Speed Automatic Bagging System - Model ZDB-900-Q8

This fully automatic bagging equipment is engineered for high-efficiency, reliable packaging of various granular materials including grains, sugar, beans, seeds, and animal feed. It seamlessly automates the entire process from bag feeding and filling to conveying and sealing.

Achieving speeds of up to 900 bags per hour, this system is constructed with premium components from global leaders to ensure maximum uptime, precision, and durability in demanding production environments.

Model: ZDB-900-Q8

Capacity: 550-900 bags/hour

Material: Heavy-duty Steel Frame, with material-contact parts available in SS304

Product Highlights

High-Capacity Bag Feeder

A dual-station system stores up to 300 bags and features automatic alarms to prevent interruptions, ensuring continuous feeding operations.

Intelligent Fault Rejection

Air pressure sensors detect and automatically remove faulty bags (e.g., failed to open) without stopping production, boosting overall efficiency.

Precision Servo Control

Key actions are driven by high-performance servo motors, enabling fast, easy adjustments for various bag specifications directly via the touchscreen interface.

Stable Bag Handling

Independent systems for bag clamping and material discharge provide superior stability, while a large 'finger' cylinder ensures a smooth, wide bag opening for efficient filling.

Technical Specifications

| Model | ZDB-900-Q8 |

| Packing Speed | 550-900 bags/hour |

| Package Weight | 5-25 kg |

| Applicable Bag Dimensions (mm) | Length: 500-800, Width: 210-380 |

| Applicable Materials | Granular materials such as rice, sugar, beans, grains, etc. |

| Air Pressure & Consumption | 0.4-0.6 MPa, 15 m³/h |

| Power Requirements | 6KW, 380/220V Three-phase five-wire |

| Bag Storage Capacity | 100-300 bags |

| Machine Dimensions (L×W×H) | 3520 × 3257 × 3250 mm |

Application Scenarios

1

Food Processing Industry

Ideal for packaging rice, sugar, salt, coffee beans, soybeans, and other food-grade granular materials.

2

Agricultural Sector

Efficiently bags bulk materials such as seeds, corn, wheat, pelleted animal feed, and fertilizers.

3

Chemical & Industrial Materials

Suitable for bagging non-corrosive plastic pellets, resins, and other industrial granular products.

4

Pet Food & Pet Care

Precisely packages various pet foods, including dry kibble, as well as materials like cat litter.

Additional Details

Premium Component Configuration for Maximum Reliability

The performance and durability of the ZDB-900-Q8 are guaranteed by using high-quality components from globally recognized brands.

| No. | Component Name | Brand / Origin |

|---|---|---|

| 1 | Touch Screen (weighing controller) | Switzerland / Mettler Toledo |

| 2 | Load Cells | USA / Celtron |

| 3 | Power Switch | Japan / Omron |

| 4 | Limit switch | Japan / Omron & Zhengtai |

| 5 | Miniature Circuit Breaker | France / Schneider |

| 6 | Button, Knob | France / Schneider |

| 7 | Intermediate Relay | Japan / Omron |

| 8 | Cylinder | Taiwan / AirTac |

| 9 | Electric Cylinder | Japan / SMC, IAI |

| 10 | Solenoid Valve | Taiwan / AirTac |

| 11 | Servo Motor | Japan / Panasonic |

| 12 | Motor | China / Gaoqi |

| 13 | Vacuum Pump | Germany / Leybold |

| 14 | Folding & Traction Machine | "Qinggong" QG4900 (Speed Regulated) |

| 15 | Stitching Machine | Japan / Newlong DS-9CW |

Our Commitment to Quality

We adhere to strict international standards throughout our production process to deliver equipment you can trust.

Material Verification: All raw materials and components are rigorously inspected upon arrival to ensure they meet our high-quality specifications.

Precision Fabrication: Structural parts are manufactured using advanced CNC machining and laser cutting to guarantee perfect alignment, strength, and durability.

Expert Assembly: Our certified technicians meticulously assemble each machine, ensuring every component is installed and calibrated for optimal performance.

Rigorous Testing: Before shipment, every machine undergoes a 72-hour continuous operation test with sample materials to validate its speed, accuracy, and stability under real-world conditions.

Service & Support

Pre-Sales Consultation: Our experts work with you to analyze your production needs, material characteristics, and facility layout to recommend the perfect packaging solution.

Installation & Training: We provide detailed manuals, remote guidance, or on-site support for installation and offer comprehensive operator training to ensure your team is proficient and safe.

Spare Parts Availability: We maintain a full inventory of all critical spare parts for immediate dispatch to minimize potential downtime.

Lifetime Technical Support: Our dedicated technical support team is available to assist with troubleshooting, maintenance questions, and operational inquiries for the life of the machine.

Frequently Asked Questions (FAQ)

Q1: What types of bags can this machine handle?

A1: The ZDB-900-Q8 is compatible with a wide range of pre-made open-mouth bags, including woven polypropylene (PP) bags, PE bags, paper bags, and multi-wall or poly-lined composite bags.

Q2: How difficult is it to switch between different bag sizes or product weights?

A2: It's very easy. Thanks to the servo-driven system and advanced PLC controller, most adjustments can be made quickly from the Mettler Toledo touch screen. You can save different job parameters as "recipes" for one-touch changeover.

Q3: Can this bagging machine be integrated into an existing production line?

A3: Absolutely. The machine is designed for seamless integration. It can be connected to your upstream feeding systems (like elevators and hoppers) and downstream equipment such as check-weighers, metal detectors, and automatic palletizers.

Q4: What is the standard maintenance required for this equipment?

A4: Routine maintenance is straightforward and includes daily cleaning, monitoring pneumatic pressures, and periodic lubrication of moving parts as outlined in the user manual. The use of premium, durable components ensures long service intervals and minimizes upkeep.