Fully Integrated Automatic Bagging Line - Model ZDB-900-Q35

High-Speed Integrated Bagging Line - Model ZDB-900-Q35

Discover our complete, end-to-end automatic bag filling and sealing system, engineered for high-throughput packaging of granular materials such as rice, grains, sugar, seeds, and various other products within the food industry and beyond.

This fully automated line integrates every stage of the process—from bag feeding and high-speed weighing to filling, sealing (stitching and heat sealing), and conveying—at speeds up to 900 bags/hour.

Model: ZDB-900-Q35

Capacity: 550-900 bags/hour

Material: Heavy-duty steel with material contact parts available in food-grade stainless steel.

Key Advantages

Dual Sealing Technology

Offers ultimate flexibility with integrated Newlong stitching and Jialong heat-sealing modules, suitable for both woven PP and PE-lined paper bags.

Intelligent Automation

Features a dual-station bag feeder (up to 300 bags) and smart sensors that detect and eject faulty bags without stopping the production line.

Unmatched Precision

Powered by a high-speed Mettler Toledo weighing controller and US/Celtron load cells, guaranteeing exceptional accuracy for consistent bag weights.

Reliable Servo Control

Major actions are driven by Panasonic servo motors, enabling smooth, fast, and easy adjustments for different packing specifications via the touch screen.

Technical Specifications

| Model | ZDB-900-Q35 |

| Packing Speed | 550-900 bags/hour |

| Weighing Range | 5-25 kg |

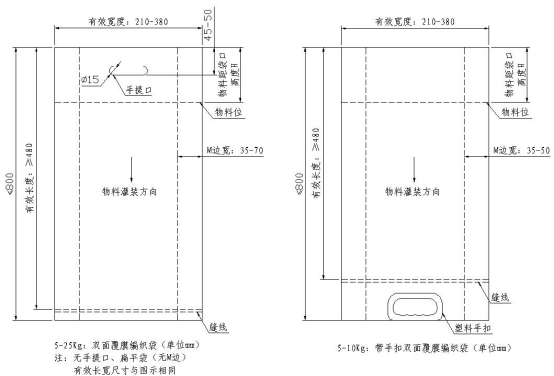

| Bag Size Range (L x W in mm) | Length: 500-800, Width: 210-400 |

| Applicable Materials | Grains, sugar, rice, seeds, pellets, and other particle material |

| Power Requirements | 6KW, 380/220V Three-phase five-wire |

| Air Consumption | 0.4-0.6 MPa · 15 m³/h |

| Bag Storage Capacity | 100-300 bags |

| Overall Dimensions (L×W×H) | 3550 × 4140 × 3250 mm |

Application Scenarios

1

Grain & Food Processing

For high-volume packaging of rice, sugar, salt, beans, and other food-grade granular material.

2

Agriculture & Animal Feed

Automated bagging of crop seeds, fertilizers, pelleted animal feeds, and aquafeeds.

3

Chemicals & Minerals

Packaging of plastic resins, PVC granules, mineral sands, and other non-corrosive industrial particles.

4

Pet Care Products

Efficiently bag large quantities of pet food kibble, cat litter, and other granular pet supplies.

System Components & Configuration

Integrated System Modules

This is a complete line solution composed of the following key mechanisms working in perfect synchronization:

Auto Bag-Giving Machine (1 Set)

High-Speed Weighing Scale (1 Set)

Main Packing & Filling Machine (1 Set)

Conveyor with Feed-in Mechanism (1 Unit)

Newlong Industrial Stitching Machine (1 Unit)

Integrated Heat Sealing Machine (1 Unit)

Premium Brand Component List

We build our machines for reliability and longevity by sourcing materials and controllers from world-renowned suppliers.

| Name | Controller / Brand |

|---|---|

| Touch Screen (weighing controller) | Switzerland / Mettler Toledo |

| Load Cells | USA / Celtron |

| Servo Motor | Japan / Panasonic |

| Intermediate Relay | Germany / Siemens |

| Circuit Breaker & Buttons | France / Schneider |

| Cylinder & Solenoid Valve | Taiwan / AirTac |

| Electric Cylinder | Japan / SMC, IAI |

| Vacuum Pump | Germany / Leybold |

| Switches | Japan / Omron & China / Zhengtai |

| Motor | China / Ziguang |

| Stitching Machine | Japan / Newlong Double Lines/4-threads |

Bag Requirements and Guidelines

The system is designed for gusseted 'M bags'. For optimal performance, bags must be flat, unglued at the mouth, and meet the specified dimensions and fill height requirements:

Bag Quality: Bags should be uniform, flat, without corner bends. The M-side gusset misalignment must be within 5mm.

Handled Bags: If using bags with handles, the handle must be at the bottom, and filling occurs from the non-handle side.

Fill Height (H): After filling, the distance from the material to the bag mouth must be at least:

- 10kg Bag: 180mm (no folding) / 220mm (with folding)

- 25kg Bag: 230mm (no folding) / 270mm (with folding)

Comprehensive Service and Support

We are dedicated to your success and provide full support throughout the lifecycle of your equipment.

Pre-Sales Consultation: Our team will help you analyze your specific needs to ensure this line is the perfect fit for your operation.

Installation & Training: We provide detailed documentation, remote support, and optional on-site services for installation and operator training.

After-Sales Support: Benefit from lifetime technical assistance and prompt availability of genuine spare parts from our inventory to maximize your uptime.