Grain Corn Rice Vacuum Bagging Machine - Model LZB-700-R6

LZB-700-R6 Grain Corn Rice Vacuum Bagging Machine

The LZB-700-R6 is a state-of-the-art vacuum bagging machine tailored for packaging grains like corn and rice. Engineered for efficiency and durability, it uses advanced vacuum technology to create airtight seals, ensuring the grains stay fresh and protected during storage and transport.

This machine is perfect for businesses aiming to streamline their packaging operations with reliable, high-performance equipment, processing 660–720 bags per hour with a weighing range of 0.5–2.5 kg.

Model: LZB-700-R6

Capacity: 660–720 bags/hour

Material: Premium stainless steel and carbon steel

Core Features

Airtight Sealing

Vacuum technology locks in freshness and extends shelf life.

High Output

Processes up to 720 bags per hour for maximum productivity.

Intuitive Controls

Features a 10-inch Omron touch screen for easy operation.

Versatility

Handles various grains, including corn, rice, and similar products.

Technical Specifications

| Model | LZB-700-R6 |

| Packing Speed | 660–720 bags/hour |

| Weighing Range | 0.5–2.5 kg |

| Power Requirements | 4N-AC 380V, 50Hz |

| Power Consumption | 5.0 kW |

| Air Consumption | 0.4–0.6 MPa, 3 m³/h |

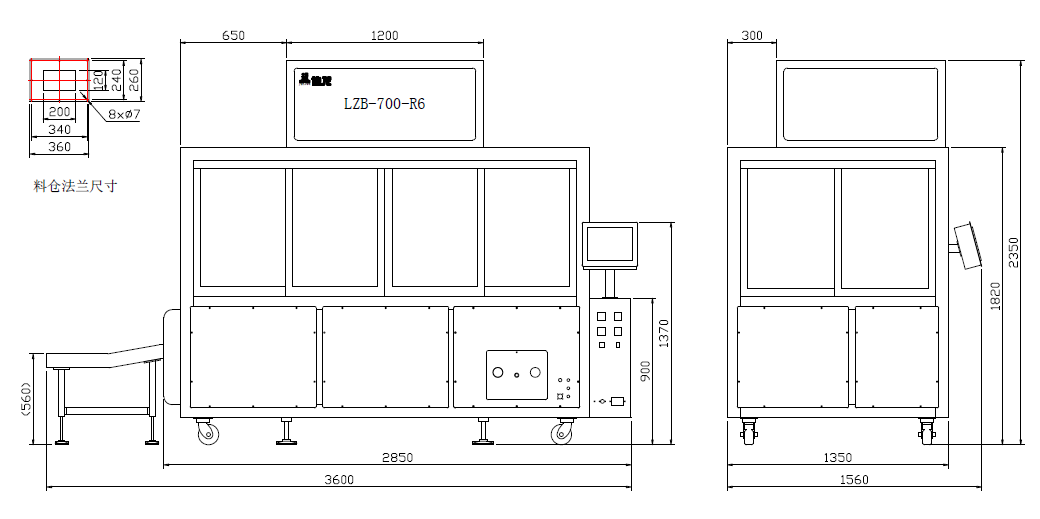

| Dimensions | 2400 mm (height, silo not included) |

| Material Standard | Premium stainless steel and carbon steel |

Application Scenarios

1

Agricultural Cooperatives

Packages grains efficiently for market distribution.

2

Food Processing Facilities

Ensures hygienic, consistent grain packaging.

3

Export Operations

Meets global standards for quality and preservation.

4

Retail Supply Chains

Delivers vacuum-sealed grains for longer freshness.

Product Description

Advanced Vacuum Bagging Solution for Grains

The LZB-700-R6 is a state-of-the-art vacuum bagging machine tailored for packaging grains like corn and rice. Engineered for efficiency and durability, it uses advanced vacuum technology to create airtight seals, ensuring the grains stay fresh and protected during storage and transport. This machine is perfect for businesses aiming to streamline their packaging operations with reliable, high-performance equipment.

Product Features

- Airtight Sealing: Vacuum technology locks in freshness and extends shelf life. - High Output: Processes up to 720 bags per hour for maximum productivity. - Intuitive Controls: Features a 10-inch Omron touch screen for easy operation. - Space-Saving Design: Compact size fits seamlessly into production lines. - Versatility: Handles various grains, including corn, rice, and similar products.

Product Advantages

Time-Saving: Boosts efficiency with rapid packaging capabilities.

Long-Lasting: Constructed from robust materials for prolonged use.

Cost-Effective: Low energy use helps reduce operational expenses.

Simple Upkeep: Modular design simplifies maintenance tasks.

Flexible Options: Adjustable settings cater to diverse packaging needs.

Working Principle

The machine operates through a series of automated steps:

Material Feeding: Grains are fed into the machine via a controlled system.

Weighing: The high-precision load cell ensures accurate weight measurement.

Bag Filling: Grains are dispensed into bags with minimal spillage.

Vacuum Sealing: The vacuum pump creates an airtight seal to preserve freshness.

Application Value

The LZB-700-R6 enhances productivity while maintaining high standards of quality and hygiene. Its advanced vacuum technology ensures grains remain fresh, making it ideal for various industries, including agriculture, food processing, and retail.

Company Advantages

- Proven Expertise: Over 15 years in the packaging machinery industry. - Worldwide Presence: Serving customers in more than 30 countries. - Innovation Focus: Ongoing investment in research and development. - Trusted Quality: Certified under ISO 9001:2015 standards.

Technical Advantages

- Smart Controls: Equipped with a Japan/Omron PLC and touch screen system. - Top-Tier Components: Includes parts from Schneider (France), Leybold (Germany), and Airtac (Taiwan). - Superior Vacuum: Powered by a Germany/Leybold pump for reliable sealing. - Accurate Weighing: Features a USA/Celtron load cell for precision.

Quality Control

Our rigorous quality process includes:

- Premium Materials: Sourcing certified stainless and carbon steel. - Skilled Assembly: Expert technicians ensure flawless integration. - Thorough Testing: Performance and safety checks at every stage. - Final Review: Detailed inspections to guarantee defect-free products.

Corporate Social Responsibility

We’re committed to sustainable practices:

- Green Technology: Energy-efficient design lowers environmental impact. - Responsible Sourcing: Collaborating with ethical, reliable suppliers. - Community Support: Backing agricultural education and local initiatives.

Pre-Sales and After-Sales Service

Pre-Sales Support: Complimentary consultations to understand your needs. Tailored demos (virtual or in-person).

After-Sales Care: 24/7 technical assistance via multiple channels. Detailed manuals and video tutorials. One-year warranty with optional extensions. On-site training and maintenance (availability varies by region).

Frequently Asked Questions

Which grains can it package? Corn, rice, and other small granular items.

Is it user-friendly? Yes, the touch screen simplifies operation, and training is provided.

What’s the warranty period? One year standard, with options to extend.

Can it accommodate different bag sizes? Yes, it adjusts to various sizes within the specified range.

How is maintenance handled? The modular build and included guides make it straightforward.

Main Configurations

| No. | Component | Supplier |

| 1 | Touch Screen 10" | Japan / Omron |

| 2 | Weighing Controller | Canada / General |

| 3 | PLC | Japan / Omron |

| 4 | Switching Power Supply | Japan / Omron |

| 5 | Solid State Relay | Japan / Omron |

| 6 | Intermediate Relay | Japan / Omron |

| 7 | Load Cell | USA / Celtron |

| 8 | Phase Sequence Relay | France / Schneider |

| 9 | Vacuum Pump | Germany / Leybold |

| 10 | Cylinder | Taiwan / Airtac |

| 11 | Solenoid Valve | Taiwan / Airtac |

| 12 | Linear Slides | Taiwan / ABBA |

| 13 | Miniature Geared Motors | Taiwan / Ruiyong |

Machine Overview: Modern industrial design with a corrosion-resistant finish.

Component Details: High-quality components sourced globally for reliability and performance.

For additional details or a personalized quote, reach out to our sales team. We’re here to deliver packaging solutions that prioritize efficiency, quality, and sustainability.