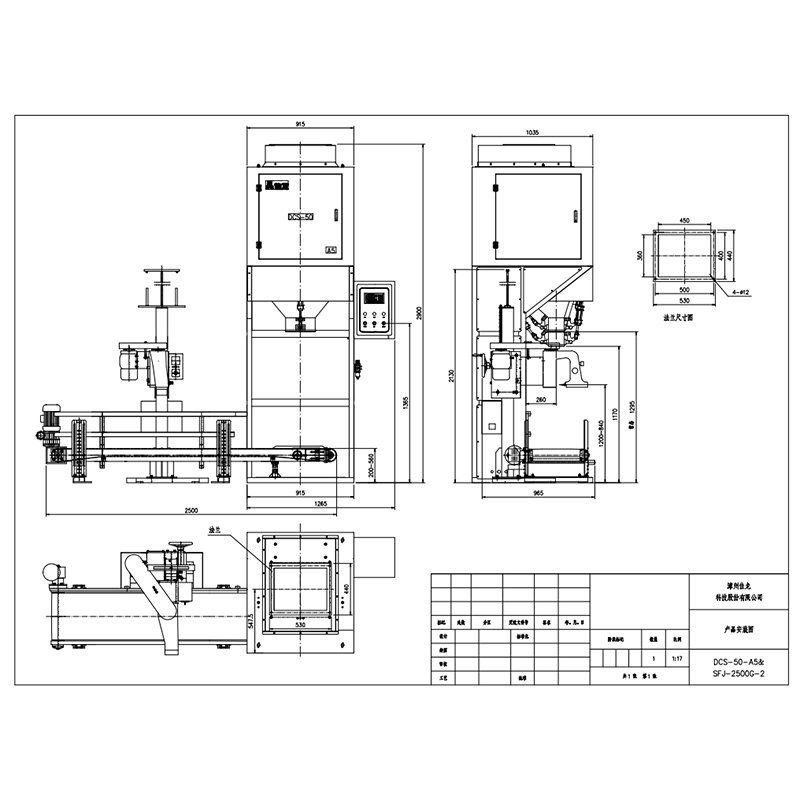

DCS-50-A5 Combination Feed Bagging System

DCS-50-A5 Bagging System for Irregular & Non-Free-Flowing Materials

Expertly engineered for materials that challenge conventional bagging machines. This system combines a gentle vibratory feeder with a powerful screw conveyor, making it the definitive solution for irregularly shaped, fragile, or non-free-flowing granular products like beans, nuts, and seeds.

This fully integrated system includes the packing scale, a screw lifting conveyor, and a sewing machine, delivering a complete, reliable, and highly versatile packaging line.

Model: DCS-50-A5

Capacity: 300-420 bags/hour

Core Technology: Vibratory & Screw Feed System

Key Advantages

Advanced Combination Feeding

The vibrator feeding system ensures a smooth, continuous material flow and prevents jams, making this the perfect soybean or wheat bagging machine for irregular products.

All-in-One Integrated Solution

This granule bagging machine comes as a complete system, including the packing scale, a robust screw lifting conveyor, and an automatic sewing machine for a seamless workflow.

High-Capacity & Smart Control

Features a single large stainless steel weighing hopper (143.5L) and a high-precision controller with auto error correction, fault diagnosis, and one-key recovery.

Stable & Accurate Weighing

The intelligent controller includes an advanced anti-vibration and anti-interference filter, ensuring the weighing process remains stable and accurate even with challenging materials.

Technical Specifications

| Model | DCS-50-A5 |

| Weighing Range | 10 - 50 kg per bag |

| Packing Speed | 300 - 420 bags/hour |

| Accuracy Grade | Class X(0.2) |

| Scale Interval (Resolution) | 10 g |

| Power Supply & Consumption | 4N-AC 380V, 50Hz, 1.5 KW |

| Air Supply & Consumption | 0.4~0.6 MPa, 2 m³/h |

| Installation Height | 2900 mm |

Main Component Configuration

| Component | Brand / Supplier |

| Weighing Controller | CA/General Measure |

| Switching Power Supply | TW/Meanwell |

| Button / Knob | FR/Schneider |

| Load Cell | CN/ZEMIC |

| Pneumatic Components (Cylinder, Solenoid Valve) | TW/Airtac |

Application Scenarios

1

Agriculture & Pulses

An exceptional soybean bagging machine, also perfect for difficult-to-handle grains like millet, wheat, beans, and various seeds.

2

Nut & Snack Food Processing

The vibratory feeder ensures gentle handling of fragile products like shelled peanuts, cashews, almonds, and large snack pieces.

3

Animal Feed & Pet Food

Effectively packages large or irregularly shaped animal feed pellets and pet food kibble that might jam other types of feeders.

4

Industrial Granules

A versatile granule bagging machine suitable for products like plastic masterbatch, wood pellets, or other non-free-flowing industrial materials.

In-Depth Details

Operational Workflow

This complete grain bagging machine system streamlines production with minimal effort. An operator hangs an empty bag on the filling spout. The vibratory feeder ensures a smooth, conditioned flow of material into the screw conveyor, which then efficiently lifts and doses the product into the large weighing hopper. The intelligent controller ensures a precise weight before discharging into the bag. The filled bag is then automatically conveyed to the sewing station, where it is securely stitched and the thread is cut, ready for dispatch.

Our Commitment to Quality and Social Responsibility

We engineer solutions built for reliability and performance. This machine features a robust frame and high-quality stainless steel for all parts in contact with the material, ensuring durability and food-grade hygiene. By integrating world-class, energy-efficient components, we help reduce our customers' operational costs and environmental footprint. Each unit is subject to rigorous testing and calibration before shipment to guarantee it meets our high standards of quality and accuracy.

Dedicated Service & Support

Expert Consultation: Our team will analyze your specific product and operational needs to ensure this system is perfectly configured to deliver optimal performance and value for your business.

After-Sales Service: We provide full support including detailed user manuals, video guides for installation and maintenance, and direct access to our technical team for any questions.

Guaranteed Spare Parts: We keep a comprehensive inventory of all key components, from controllers and load cells to pneumatic parts, ensuring fast delivery to keep your production running smoothly.

Data Integration Ready: The machine is equipped with a reserved RS232/485 interface, making it simple to connect to factory management and data acquisition systems.

Frequently Asked Questions (FAQ)

Q1: Why does this machine use both a vibratory feeder and a screw conveyor?

A: This combination is specifically for materials that do not flow easily. The vibratory feeder breaks up any clumps and provides a consistent, manageable flow of material into the screw conveyor. The screw conveyor then provides the positive force needed to lift and dose the material accurately. This dual system overcomes the challenges of packing irregular or fragile products.

Q2: Can I adjust the feeding speed for different materials?

A: Yes. The three-level feeding system (fast, medium, slow/trickle) can be adjusted through the controller interface to optimize speed and accuracy for each specific material you are packaging.

Q3: Is the system difficult to clean between runs of different products?

A: The design prioritizes ease of cleaning. With its large single hopper and the use of stainless steel for all contact parts, the machine can be cleaned thoroughly with relative ease to prevent cross-contamination between different batches.