LCJ-20T-6 High-Throughput Grains Mixing Machine

LCJ-20T-6 Continuous Flow Scale & Grains Mixer

Engineered for industrial-scale grain processing, chemical plants, and port logistics, the LCJ-20T-6 Grains Mixing Machine offers unparalleled precision in continuous, automated blending operations.

This advanced grains mixer uses an intelligent flow measurement system to handle a wide range of granular materials with exceptional accuracy and a throughput of up to 20 tons per hour, ensuring consistent quality and maximizing operational efficiency.

Model: LCJ-20T-6

Capacity: Up to 20 Tons/Hour

Core Technology: Continuous Flow Measurement & Dosing

Key Advantages

High-Capacity Throughput

Designed for heavy-duty industrial applications with a maximum output of 20T/h per channel, enabling high-volume blending and material transfer.

Precision Flow Control

Features an intelligent flow correction system to maintain stable rates and high accuracy (≤0.5%), critical for consistent product quality. The triple-sensor support ensures rapid material response.

Advanced Automation & Safety

Includes a quantitative output mode, an alarm-stop function, and a one-button clearing feature. Communication ports allow easy integration with central control systems.

Versatile & Clean Operation

Its residue-free internal design and dual feeding control system adapt to various granular materials and ensure fast, clean operation with minimal cross-contamination.

Technical Specifications

| Parameter | Model: LCJ-20T-6 |

| Capacity (Flow Rate) | 0.2 - 20 Tons/Hour |

| Accuracy | ≤0.5% |

| Power Consumption | 0.3 KW |

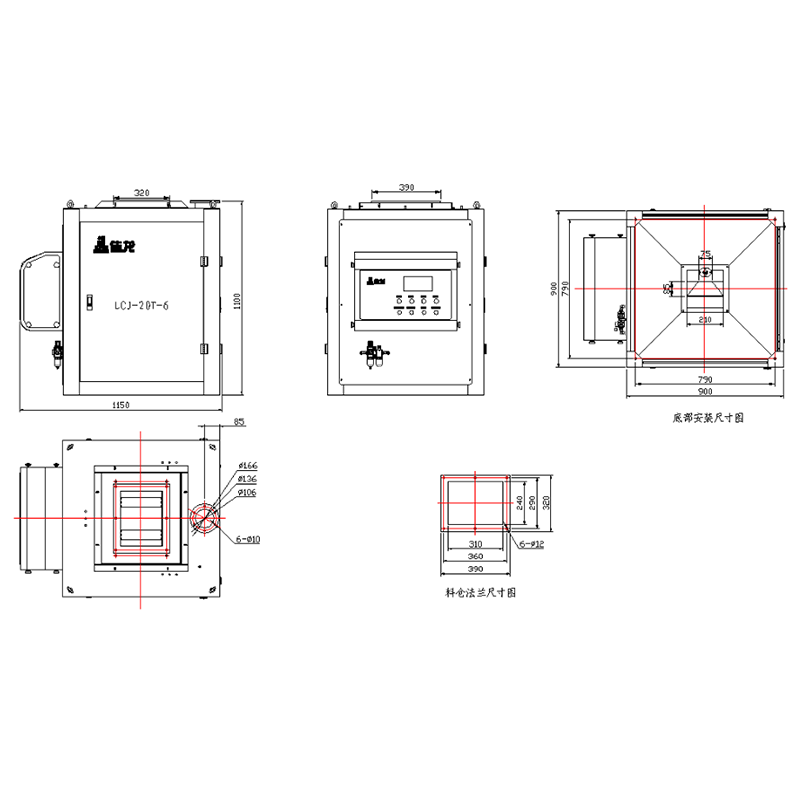

| Installation Dimensions (L×W×H) | 900 mm × 1150 mm × 850 mm |

Main Component Configuration

| Component | Brand / Supplier | Function |

| Weighing Controller | Harbin/Zhiyuanda | Core processing & control |

| Load Cell Sensor | America/Celtron | High-precision weighing |

| Low-Voltage Electricals | French/Schneider | Safe & reliable power control |

| Gear Reducer | Taiwan/Ruiyong | Durable power transmission |

| Pneumatic Element | Taiwan/Airtac | Stable gate actuation |

Application Scenarios

1

Multi-Ingredient Blending

Combine multiple Grains Mixer units to create a sophisticated, high-volume blending line for grains, cereals, or animal feed recipes.

2

In-Line Process Control

Integrate into your production line to regulate and monitor the flow of granular materials to downstream equipment like packaging systems or chemical reactors.

3

Bulk Material Transfer

Use in port logistics or large-scale storage facilities for precisely controlled loading and unloading of ships, trucks, or silos by weight.

4

Quantitative Batching

Accurately prepare large, specific-weight batches of raw materials before they are moved to large-scale mixers, cookers, or processing tanks.

In-Depth Details

Operational Principle

The LCJ-20T-6 is a sophisticated "loss-in-weight" feeder. It operates by precisely measuring the decrease in weight of the material in its integrated hopper as it is discharged. The intelligent weighing controller continuously compares this real-time weight loss against the operator's set flow rate (e.g., tons per hour). It instantly adjusts the discharge gate via the gear reducer to maintain a constant, highly accurate flow of material, making it an ideal Grains Mixing Machine for continuous processes.

Our Commitment to Quality and Sustainability

We build our equipment for durability and performance in the most demanding industrial settings. This grains mixer features a robust, residue-free internal design to ensure product purity and fast, easy cleanouts. We are committed to sustainability by using energy-efficient components, such as the low-power gear reducer, to reduce operational costs and environmental impact. Every unit is manufactured with world-class components and undergoes rigorous testing to guarantee quality, accuracy, and reliability.

Dedicated Customer & Technical Support

Process & Application Consulting: Our technical experts will partner with you to analyze your production needs and material characteristics, helping design a blending or dosing system that maximizes your efficiency.

Installation and Operational Support: We provide comprehensive documentation and remote technical assistance from our engineers to ensure a smooth installation, setup, and commissioning process.

Lifetime Technical Service: Our commitment to your success extends for the life of the machine, with our support team ready to assist with any operational questions or troubleshooting needs.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of this machine compared to a batch mixer?

A: While a batch mixer mixes a fixed quantity at one time, this machine is a continuous flow scale. Its primary advantage is its ability to be part of an uninterrupted production line, continuously dosing and blending materials at a precise flow rate, which is ideal for large-volume operations.

Q2: Can I integrate this Grains Mixer with my existing plant control system (e.g., PLC or SCADA)?

A: Yes. The machine is designed for modern industrial environments and includes communication ports (like RS232/485) that allow for integration with higher-level central control and management systems.

Q3: How does the "triple-sensor" design improve performance?

A: The triple-sensor configuration provides greater stability and faster signal response for the weighing system. This reduces the impact of external vibrations and ensures that the controller receives accurate weight data more quickly, allowing for finer and more responsive control over the material flow.