Automatic Packaging Machine - Model LZB-100-R20

LZB-100-R20 Automatic Packaging Machine

The LZB-100-R20 is a state-of-the-art automatic packaging machine engineered for precision, speed, and reliability. Designed to handle both granular and powder materials, this machine is a versatile solution for industries seeking efficient and consistent packaging.

Its robust construction and cutting-edge technology make it a standout choice for high-performance production lines, processing 600–1000 bags per hour with a weighing range of 0.35–5 kg.

Model: LZB-100-R20

Capacity: 600–1000 bags/hour

Material: Stainless steel (contact parts), carbon steel frame

Core Features

Accurate Weighing

Incorporates a USA/Celtron load cell and Canada/General weighing controller for precise measurements down to 1 gram.

Intuitive Operation

Features a 10-inch Omron touch screen from Japan, offering a user-friendly interface and real-time monitoring.

Premium Components

Built with globally renowned parts from Schneider (France), Leybold (Germany), and Airtac (Taiwan) for unmatched reliability.

Versatility

Handles a broad spectrum of materials, from grains to fine powders, catering to diverse industry needs.

Technical Specifications

| Model | LZB-100-R20 |

| Packing Speed | 600–1000 bags/hour (depending on material and bag size) |

| Weighing Range | 0.35–5 kg |

| Scale Interval | 1 gram |

| Precision Grade | X(0.5) |

| Power Requirements | 4N-AC 380V, 50Hz |

| Power Consumption | 5.5 kW |

| Air Consumption | 0.4–0.6 MPa, 14 m³/h (air supply provided by the customer) |

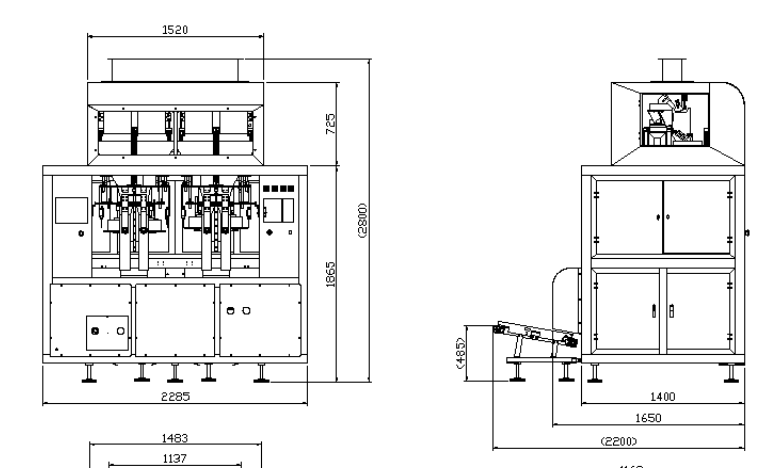

| Dimensions | 2300 mm (L) × 2200 mm (W) × 2800 mm (H) |

| Material Standard | Stainless steel for contact parts, carbon steel frame |

Application Scenarios

1

Food Processing

Perfect for packing grains, spices, and flour while meeting hygiene standards.

2

Chemical Production

Safely handles powders and granular chemicals with precision.

3

Agriculture

Ideal for seeds, fertilizers, and other farm products requiring efficient packaging.

4

Pharmaceuticals

Supports controlled packaging of powdered or granular medical goods.

Product Description

Advanced Packaging Solution for Granular and Powder Materials

The LZB-100-R20 is a state-of-the-art automatic packaging machine engineered for precision, speed, and reliability. Designed to handle both granular and powder materials, this machine is a versatile solution for industries seeking efficient and consistent packaging. Its robust construction and cutting-edge technology make it a standout choice for high-performance production lines.

Product Features

- Accurate Weighing: Incorporates a USA/Celtron load cell and Canada/General weighing controller for precise measurements down to 1 gram. - Intuitive Operation: Features a 10-inch Omron touch screen from Japan, offering a user-friendly interface and real-time monitoring. - Premium Components: Built with globally renowned parts from Schneider (France), Leybold (Germany), and Airtac (Taiwan) for unmatched reliability. - Space-Saving Design: Compact dimensions optimize factory floor space without compromising functionality. - Versatility: Handles a broad spectrum of materials, from grains to fine powders, catering to diverse industry needs.

Product Advantages

High Output: Processes up to 1000 bags per hour, enhancing productivity in fast-paced environments.

Longevity: Constructed with durable materials to withstand rigorous use over time.

Cost Efficiency: Low power consumption (5.5 kW) reduces operational expenses.

Ease of Maintenance: Modular design simplifies servicing and minimizes production interruptions.

Adaptability: Adjustable settings accommodate various bag sizes and material types for tailored performance.

Working Principle

The machine operates through a series of automated steps:

Material Feeding: Materials are fed into the machine via a controlled system.

Weighing: The high-precision load cell ensures accurate weight measurement.

Bag Filling: Materials are dispensed into bags with minimal spillage.

Sealing: The vacuum pump assists in sealing the bags efficiently.

Application Value

The LZB-100-R20 enhances productivity while maintaining high standards of accuracy and hygiene. Its adaptability makes it suitable for various industries, reducing operational costs and improving efficiency.

Company Strengths

- Proven Expertise: Over 15 years of leadership in packaging machinery design and manufacturing. - Worldwide Presence: Serving clients in more than 30 countries across food, chemical, and agricultural sectors. - Innovation Focus: Continuous investment in research and development to deliver cutting-edge solutions. - Quality Commitment: ISO 9001:2015 certification reflects our dedication to excellence.

Technical Strengths

- Advanced Automation: Powered by a Japan/Omron PLC and touch screen for seamless control and integration. - Smooth Operation: Taiwan/Airtac cylinders and solenoid valves ensure consistent performance. - Efficient Sealing: A Germany/Leybold vacuum pump enhances material handling and bag sealing. - Stable Precision: Taiwan/ABBA linear slides and USA/Celtron load cells provide reliable accuracy.

Quality Control

Our production process prioritizes excellence:

- Top-Grade Materials: Sourced from certified suppliers, ensuring stainless steel and carbon steel Magneto ensures consistent quality. - Expert Assembly: Components are carefully integrated and tested for optimal performance. - Thorough Testing: Machines undergo load, accuracy, and stress tests to meet X(0.5) precision benchmarks. - Final Checks: Comprehensive inspections guarantee defect-free delivery.

Corporate Social Responsibility

We strive for sustainability and community impact:

- Eco-Conscious Design: Minimizes energy use and waste during operation. - Responsible Sourcing: Partnerships with suppliers uphold ethical and environmental standards. - Community Support: Training programs and collaborations with agricultural cooperatives uplift local areas.

Pre-Sales and After-Sales Service

Pre-Sales: Free consultations to understand your needs. Tailored solutions and demonstrations (on-site or virtual).

After-Sales: 24/7 technical support via multiple channels. Detailed manuals and videos for setup and operation. One-year warranty, with options to extend. Maintenance and training services available (region-dependent).

Frequently Asked Questions

What materials is it suited for? Granular and powder materials like grains, chemicals, and fertilizers.

How easy is it to use? The Omron touch screen simplifies operation, and we provide training support.

What’s the warranty? One year standard, with extended plans available.

Can it be customized? Yes, settings can be adjusted for different bag sizes and materials.

How is maintenance handled? Modular components and detailed guides make it straightforward, with our team ready to assist.

Main Configurations

| No. | Component | Brand |

| 1 | Touch Screen 10" | Japan / Omron |

| 2 | Weighing Controller | Canada / General |

| 3 | PLC | Japan / Omron |

| 4 | Switching Power Supply | Japan / Omron |

| 5 | Solid State Relay | Japan / Omron |

| 6 | Intermediate Relay | Japan / Omron |

| 7 | Load Cell | USA / Celtron |

| 8 | Phase Sequence Relay | France / Schneider |

| 9 | Vacuum Pump | Germany / Leybold |

| 10 | Cylinder | Taiwan / Airtac |

| 11 | Solenoid Valve | Taiwan / Airtac |

| 12 | Linear Slides | Taiwan / ABBA |

Machine Overview: A modern silver-gray finish with a sleek, industrial aesthetic.

Component Details: High-quality components sourced globally for reliability and performance.

For inquiries or a personalized quote, reach out to our sales team. We’re here to deliver packaging solutions that combine precision, efficiency, and reliability.