LZB-500-FR15 Dual-Mode Automatic Vacuum Packaging Machine for Granules

LZB-500-FR15 Dual-Mode Packaging Solution

A highly versatile and intelligent packaging solution engineered for the high-speed vacuum sealing of granular products. Offering the unique flexibility to produce both sleek, flat-shaped packages and perfectly uniform, brick-shaped packages.

Model: LZB-500-FR15

Capacity: Cubic: 300-500; Flat: 180-240 bags/hr

Material: Food-grade stainless steel contact parts

Product Highlights

Dual-Function Versatility

Produces both flat and cubic (brick-shaped) vacuum packages on one machine, meeting diverse needs and saving space.

Intuitive "One-Touch" Operation

Central control via Siemens PLC and Touch Screen provides a "fool-style" simple interface for easy operation and maintenance.

Rapid, Tool-Free Changeovers

Switch packaging specifications in under 3 minutes without auxiliary tools, minimizing downtime and maximizing throughput.

Engineered for Reliability

Built with premium components from renowned brands like Siemens, Omron, and Schneider to ensure reliability and a long service life.

Technical Specifications

| Parameter | Value |

| Model | LZB-500-FR15 |

| Weighing Range | Brick Shape: 0.5 - 5 kg Flat Shape: 1 - 10 kg |

| Operational Speed | Cubic (Brick) Shape: 300 - 500 bags/hour Flat Shape: 180 - 240 bags/hour |

| Scale Interval | 2 g |

| Accuracy Grade | X(0.5) |

| Power & Consumption | 4N-AC 380V 50Hz, 6.0KW |

| Required Air Pressure | 0.4 - 0.6 MPa |

| Air Consumption | 22 m³/h |

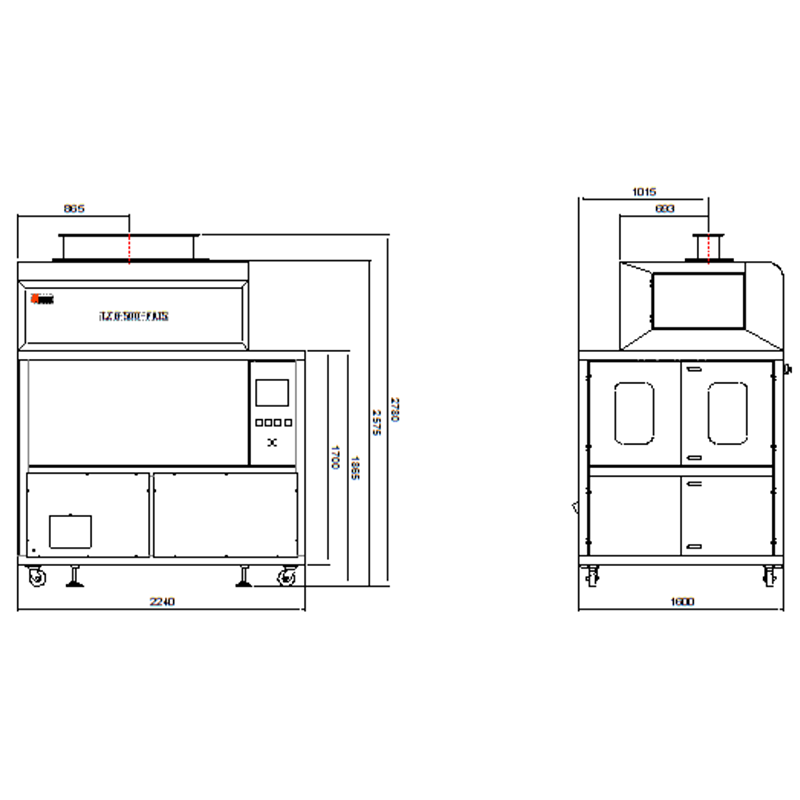

| Machine Dimensions (L×W×H) | 2240 × 1800 × 2780 mm |

| Primary Materials | Food-grade stainless steel contact parts; heavy-duty carbon steel frame. |

Application Scenarios

1

Agriculture & Food Industry

Perfectly suited for groundnuts, beans, rice, millet, lentils, coffee beans, sugar, and other whole grains.

2

Pet Food Industry

Excellent for premium dry pet food, cat litter, and specialty animal feeds, where an airtight seal locks in freshness.

3

Chemical Industry

Can be used for non-corrosive granular materials like plastic pellets and certain types of granulated fertilizers.

4

High-Value Goods

Ideal for any product where premium package appearance, long shelf life, and logistical efficiency are required.

Technical Advantage & Quality Control

Production & Quality Assurance Process

From raw material selection to final assembly, every LZB-500-FR15 machine undergoes a rigorous quality control protocol. The manufacturing process includes precision laser cutting of the frame, expert assembly, and a comprehensive, multi-stage testing procedure. Before shipment, each machine must pass a full system calibration and a 24-hour continuous operational test under load.

Premium Component Sourcing

We leverage a global supply chain of trusted, world-class manufacturers to ensure every component contributes to the machine's overall performance and longevity.

| No. | Component | Supplier | Origin |

| 1 | Touch Screen | Siemens | Germany |

| 2 | Weighing Controller | High Speed Mode Controller | - |

| 3 | PLC | Siemens | Germany |

| 4 | Power Supply | Omron | Japan |

| 5 | Solid State Relay | Omron | Japan |

| 6 | Intermediate Relay | Siemens | Germany |

| 7 | Load Cell | Celtron | USA |

| 8 | Phase Order Protector | Schneider | France |

| 9 | Vacuum Pump | ZD | China |

| 10 | Cylinder | Airtac | Taiwan |

| 11 | Solenoid Valve | Airtac | Taiwan |

| 12 | Linear Track | Airtac | Taiwan |

Our Company Advantages

Innovative Engineering: Our dedicated R&D team continuously works to integrate the latest technology, making our machines more efficient, versatile, and user-friendly.

Customization Solutions: We understand that every production line is unique. We work closely with our clients to tailor machine configurations to their specific product, material, and facility requirements.

Global Service Network: We provide comprehensive support to clients around the world, from initial consultation to long-term technical assistance.

Pre-Sales & After-Sales Service

Pre-Sales Service

Detailed Consultation: We conduct an in-depth needs analysis to ensure the LZB-500-FR15 is the perfect fit for your application.

Sample Material Testing: Send us your product, and we will create sample packages for your evaluation, demonstrating the final packed quality.

Facility Integration Planning: Our experts can assist with layout design to ensure seamless integration into your production line.

After-Sales Service

Professional Installation & Training: We offer on-site or remote support for machine installation, setup, and thorough operator training.

Responsive Technical Support: Our dedicated technical team is on standby to provide prompt troubleshooting via phone, email, or video call.

Reliable Spare Parts: We maintain a complete inventory of all critical spare parts to ensure rapid delivery and minimize any potential downtime.

Corporate Social Responsibility

We are committed to sustainable manufacturing principles. The LZB-500-FR15 is designed with energy-efficient components to reduce power consumption. Furthermore, the practice of vacuum sealing extends product shelf life, helping to reduce food waste. Our use of advanced filtration systems also ensures a cleaner, safer workplace and environment.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of choosing between a flat and a brick-shaped package?

A1: Brick-shaped packages are rigid and highly stable, making them ideal for neat, efficient stacking on pallets and retail shelves. Flat-shaped packages offer a larger surface area for branding and can be more flexible for certain products. This machine gives you the ability to produce both to meet any need.

Q2: Is the machine really easy to adjust for different package sizes?

A2: Absolutely. The machine is engineered for rapid, tool-free adjustments. The entire process of changing the forming mold and adjusting parameters on the Siemens touch screen can be completed in under three minutes by a trained operator.

Q3: Why is the sourcing of components like Siemens and Celtron so important?

A3: Using high-quality components from globally respected brands directly translates to higher machine reliability, better performance accuracy, and a longer operational lifespan. It minimizes the risk of unexpected breakdowns and ensures consistent production.

Q4: Can the machine handle very dusty products like flour or fine powders?

A4: The LZB-500-FR15 is specifically designed for granular materials. While it can handle some dust, it is not optimized for fine powders. For floury or powdery products, we would recommend a different model from our auger-filler packaging machine series.