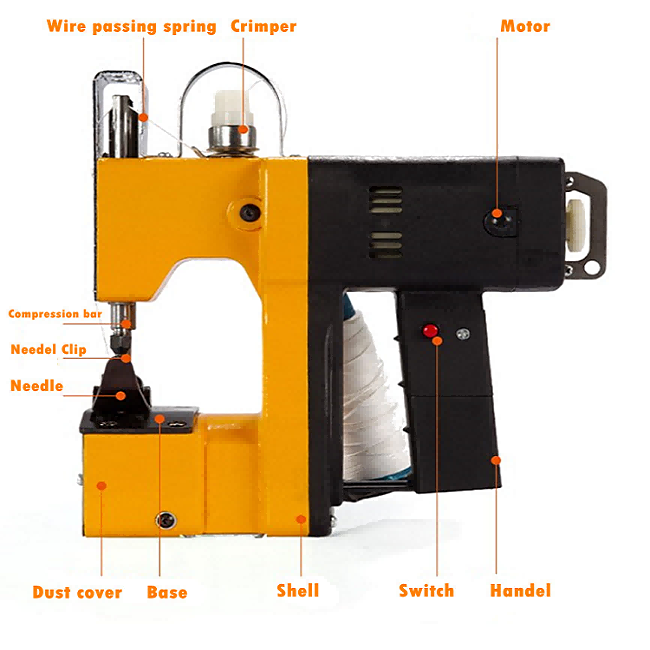

GK-26 Portable Single-Stitch Bag Sewing Machine

GK-26 Portable Handle Stitching Machine

Experience unparalleled portability and efficiency with the GK-26 Handle Sewing Machine. This lightweight yet robust stitching machine is engineered for fast, secure closing of all types of bags, including paper, burlap, plastic, cotton, and PP woven fabrics.

Featuring a newly developed ergonomic handle and an advanced built-in lubrication system, this single stitch machine delivers smooth, high-speed performance, reduces operator fatigue, and ensures a long service life, making it the ideal choice for industrial, agricultural, and commercial packaging.

Model: GK-26 Series

Stitch Type: Single-Thread Chainstitch

Key Feature: Portable, Lightweight, High-Speed

Key Advantages

Lightweight & Ergonomic

The compact, lightweight design and enhanced slip-resistant handle ensure excellent grip and reduced operator fatigue, making it perfect for both mobile and stationary use.

High-Speed & Efficient

Achieves a maximum sewing speed of 1700 stitches per minute and features an automatic thread cutter, allowing for rapid and clean bag closures to boost productivity.

Built-in Lubrication System

This advanced handle sewing machine includes an internal oiling device that automatically lubricates moving parts, significantly prolonging machine lifespan and reducing maintenance.

Wide Material Compatibility

This versatile stitching machine is capable of securely closing a wide variety of bag materials, including kraft paper, PP/PE woven cloth, cotton, hessian, and jute.

Technical Specifications

| Parameter | GK-26 Series |

| Max. Sewing Speed | 1700 stitches/minute |

| Stitch Type & Length | 1-Thread Chainstitch / 8.5 mm (Fixed) |

| Compatible Bag Materials | Kraft paper, PP/PE woven cloth, cotton, hessian, jute |

| Needle / Thread Type | DNx5, #135×525 / 2x3 Vinylon, Synthetic, or Cotton |

| Drive Motor | 220V, 190W |

| Weight (Net / Gross) | 2.8 kg / 3.5 kg |

Application Scenarios

1

Agriculture & Farming

Perfect for closing bags of seeds, animal feed, fertilizer, and harvested produce like potatoes or grains directly in the field or warehouse.

2

Industrial & Chemical

Quickly and securely seal PP woven or paper sacks of chemicals, minerals, sand, coal, or other bulk industrial materials.

3

Milling & Food Processing

An essential stitching machine for sealing bags of flour, sugar, salt, rice, and other bulk food ingredients in milling and processing plants.

4

Logistics & Post Services

Ideal for closing mailbags, burlap sacks, and other large parcels in postal centers, courier services, and warehouse operations.

In-Depth Details

Engineering and Quality Assurance

The GK-26 Series Handle Sewing Machine is engineered for maximum durability and operator comfort. It is constructed with a high-quality die-cast aluminum housing for lightweight strength and features precision-machined steel components for critical moving parts. Our commitment to reliability is evident in the machine's ability to operate for extended periods under demanding conditions. Each single stitch machine undergoes rigorous factory testing to ensure it meets our standards for stitch quality, speed consistency, and overall mechanical performance.

Our Commitment to Service and Support

Application Guidance: Our team is available to help you select the correct needle and thread combination for your specific bag materials, ensuring you achieve the strongest and most reliable seal possible.

Maintenance & Operation: Every stitching machine comes with a detailed user manual covering operation, routine maintenance, and the simple lubrication process. Our support team is also available to answer any questions.

Readily Available Spare Parts: We maintain a comprehensive stock of all necessary spare parts, including needles, loopers, feed dogs, and motors, to ensure your machine can be quickly serviced and kept in peak condition.

Frequently Asked Questions (FAQ)

Q1: What is a single-thread chainstitch, and is it strong enough?

A: A single-thread chainstitch uses one continuous thread that loops together to form the seam. It is a very common and strong stitch for industrial bag closing. While it's easy to unravel by pulling the correct end of the thread (for quick opening), the stitch holds securely under the weight and stress of normal handling and transport.

Q2: How does the built-in lubrication system work?

A: The handle sewing machine features an internal oil pump with a reservoir. Pressing a button on the oiler automatically delivers a small amount of lubricant directly to the main moving parts, such as the looper and linkages. This simplifies maintenance and ensures the machine remains well-lubricated for smooth operation.

Q3: Can this machine be used in a fixed position, or is it only for handheld use?

A: While designed for portability, this stitching machine is highly versatile. It can be used as a handheld device for maximum flexibility or mounted on a spring balancer suspension system. This allows the operator to effortlessly bring the machine down to the bag, sew the closure, and release it, which is ideal for stationary, repetitive bagging stations.