LCJ Series High-Capacity Continuous Flow Scale

LCJ Series Continuous Blending & Flow Measurement System

Unlock superior control over your production line with the LCJ Series, an advanced industrial blending machine engineered for precise, continuous flow measurement of granular materials.

Designed for high-capacity applications up to 20 tons per hour, this system is perfect for rice blending, grain batching, and other industrial processes where accurate material proportioning and filling are critical for product quality and operational efficiency.

Function: Continuous Blending & Flow Measurement

Capacity: Up to 20 Tons/Hour

Core Technology: Dynamic Flow Control & Measurement

Key Advantages

High-Capacity Throughput

Designed for industrial-scale operations, with models offering a maximum single-channel output of up to 10T/h or 20T/h to meet demanding production schedules.

Precision Flow Control

Achieve exceptional blending accuracy of ±0.2% with automatic flow measurement correction, ensuring consistent product quality and recipe adherence.

Intelligent Automation

Features a flexible ratio range (1:40) with an automatically adjusting discharge port. The one-button material clearing function simplifies cleaning between batches.

Residue-Free & Adaptable

Independently controlled dual feeding mechanisms and a non-residue structural design provide fast, stable performance with strong adaptability to various granular materials.

Technical Specifications

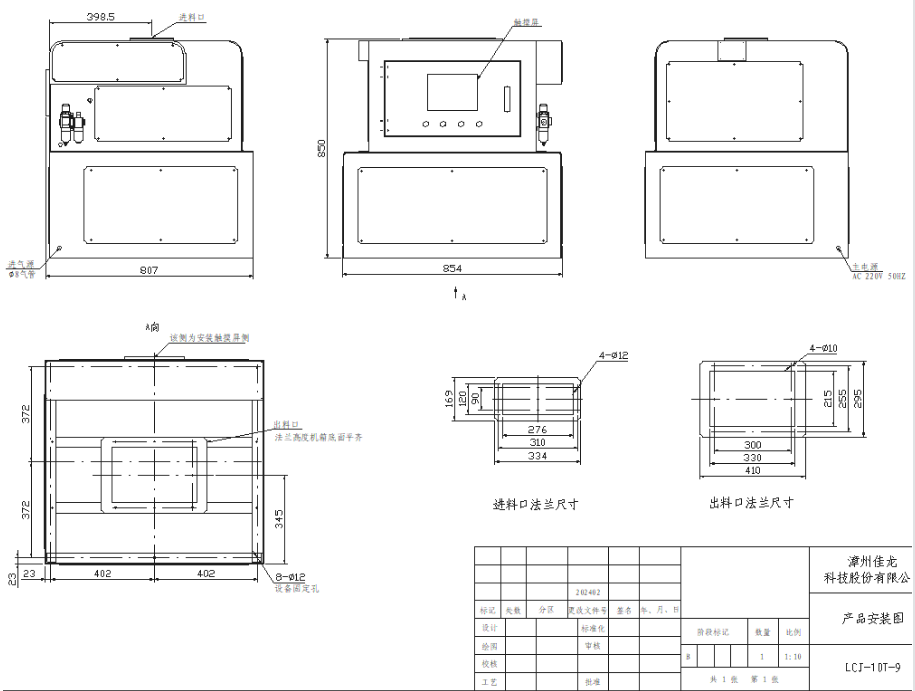

| Parameter | Model: LCJ-10T-9 | Model: LCJ-20T-9 |

| Capacity (Throughput) | 0.3 - 10 Tons/Hour | 0.5 - 20 Tons/Hour |

| Accuracy | ±0.2% | |

| Power Supply & Consumption | AC 220V, 50Hz, 30W | |

| Air Supply & Consumption | 0.4~0.6 MPa, 1 m³/h | |

| Dimensions (L×W×H) | 854 × 807 × 850 mm | 854 × 807 × 1050 mm |

| Weighing Hopper Capacity | 23 Liters | 32 Liters |

| Working Temperature | 0 ~ 45°C | |

Note: Stated accuracy and speed are based on internal tests using round grain rice. Actual performance may vary depending on material characteristics, supply consistency, and environmental factors.

Main Component Configuration

| Component | Brand / Supplier |

| Weighing Controller | China/General Measure |

| Power Switch | Taiwan/Meanwell |

| Button / Knob | French/Schneider |

| Load Cell | China/ZEMIC |

| Step Motor | Shenzhen/Leisai |

| Pneumatic Element | Taiwan/Airtac |

Application Scenarios

1

Rice Blending & Processing

The ultimate industrial rice blending machine for creating consistent mixtures of different rice varieties based on precise weight ratios.

2

Grain Batching & Mixing

Accurately measure and blend various granular materials like millet, soybeans, and mung beans to create mixed grain products or animal feed formulas.

3

In-Line Flow Regulation

Use as a high-precision flow measurement device to regulate and monitor the flow of material to downstream equipment like packaging machines or extruders.

4

Bulk Loading & Filling

Efficiently perform bulk blending and filling into large containers, bags, or silos by precisely controlling the total weight of the discharged batch.

In-Depth Details

Operational Principle

The LCJ Series operates as a continuous loss-in-weight feeder. Material flows from an upstream hopper into the machine's weighing hopper. An intelligent controller continuously monitors the weight of the material in the hopper. It then precisely controls the opening of the discharge gate via a step motor to release material at a set, constant flow rate (e.g., tons per hour). The system automatically performs real-time corrections to maintain a highly accurate flow measurement, ensuring the perfect amount of material is dosed for blending or filling applications.

Commitment to Quality and Engineering

We build our industrial blending machines for durability and precision in demanding environments. The LCJ Series features a robust, non-residue structural design to ensure clean operation and minimize cross-contamination between batches. By integrating premium components from globally recognized suppliers, we guarantee stable performance and a long service life. Every machine is rigorously tested for accuracy and flow rate stability before shipment, ensuring it meets the highest standards of quality.

Comprehensive Service & Support

Application Consultation: Our technical experts will analyze your process requirements, material characteristics, and facility layout to provide a tailored blending and filling solution that optimizes your workflow.

Technical Support: We offer comprehensive after-sales support, including detailed installation guides, operating manuals, and remote assistance from our expert engineers to ensure smooth integration and operation.

Guaranteed Parts Availability: We maintain a full inventory of all critical components, including controllers, load cells, step motors, and pneumatic elements, for fast delivery to minimize any operational interruptions.

Frequently Asked Questions (FAQ)

Q1: Can I use this machine to blend more than two materials?

A: Yes. A typical blending system is created by combining multiple LCJ units. For example, to blend three types of rice, you would use three separate machines, each set to the desired flow rate. They would all discharge onto a common conveyor to create the final blended product.

Q2: How does the "automatic flow measurement correction" work?

A: The controller continuously compares the actual weight loss in the hopper to the target flow rate. If it detects any deviation (e.g., due to changes in material density), it instantly adjusts the discharge gate opening to correct the flow, ensuring real-time accuracy.

Q3: Is this machine difficult to operate?

A: No, it is designed for user-friendly operation. The main parameters, such as the target flow rate (t/h) and the total batch weight, are easily set through the controller interface. The machine's automated functions handle the complex adjustments internally.