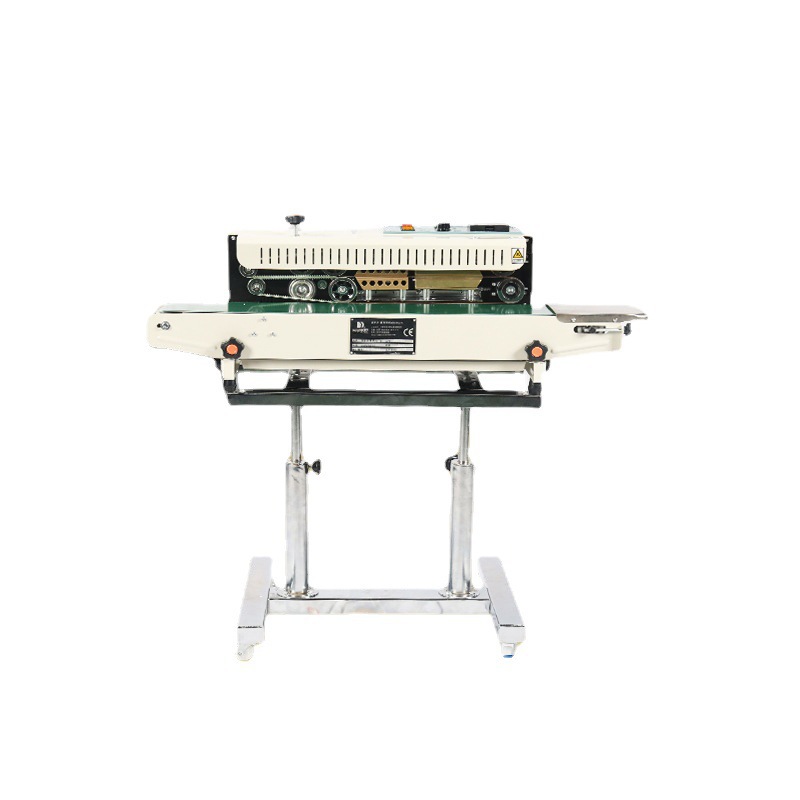

FRL600 Series Continuous Vacuum & Gas Flush Heat Sealer

FRL600 Series Multi-Function Continuous Band Sealer

Achieve superior, professional-grade packaging with the highly versatile FRL600 Series continuous heat sealer. This advanced bag sealing equipment is designed for high-efficiency horizontal sealing and comes equipped with optional gas flushing, vacuum sealing, and an integrated date coding system.

It is the perfect all-in-one solution for sealing a wide range of bag materials, delivering a strong and clean 13mm wide seal that extends product shelf life and provides a premium, retail-ready appearance.

Series: FRL600

Functions: Sealing, Vacuum, Gas Flushing, Date Coding

Seal Width: 13 mm

Key Advantages

Multi-Functional Sealing

This integrated system combines continuous heat sealing with powerful vacuum sealer and gas flushing options to extend product shelf life, all in one compact unit.

Professional 13mm Seal

Creates a strong, extra-wide, and aesthetically pleasing seal that is perfect for high-end retail packaging and ensures maximum product protection and integrity.

Wide Material Compatibility

Expertly handles a vast range of materials, from standard PP and PE films to thick metallized foils, paper-foil laminates, and other composite packaging.

Integrated Date Coding

Includes a built-in solid-ink roller printer for applying expiry dates, batch numbers, or other tracking information directly onto the seal area for full traceability.

Technical Specifications

| Parameter | Model: FRL-600AS | Model: FRL-600BS |

| Sealing Speed | 0 - 15 m/min (Adjustable) | |

| Applicable Film Thickness (Single Layer) | 0.04 - 0.2 mm | |

| Sealing Width / Length | 13 mm / Unlimited | |

| Sealing Temperature | 0 - 300°C (Adjustable) | |

| Power Supply | AC 220V/50Hz or 110V/60Hz | |

| Conveyor Height Adjustment | 120 mm - 600 mm | |

| Max. Conveyor Load / Per Bag | 20 kg / 5 kg | |

| Total Power | 930 W | 1080 W |

| Machine Size / Packing Size (L×W×H) | 1300×520×1360 mm / 1220×570×1420 mm | |

| Net / Gross Weight | 84 kg / 128 kg | 86 kg / 130 kg |

Application Scenarios

1

Food & Snack Packaging

The perfect vacuum sealer for bags of coffee, tea, nuts, snacks, and other perishable goods where gas flushing can extend shelf life.

2

Pharmaceuticals & Medical

This heat sealer provides sterile, airtight seals for packaging medical supplies, powders, and pharmaceuticals, with date and batch coding for full traceability.

3

Cosmetics & Personal Care

Delivers clean, professional seals for sample pouches, sachets, and small bags of lotions, powders, and other cosmetic products.

4

Industrial & Electronic Parts

Effectively seals bags of small industrial components, electronic parts, or hardware, protecting them from moisture, dust, and environmental factors.

In-Depth Details

Operational Workflow

The FRL600 Series offers a simple yet highly efficient workflow. The operator places the open end of a filled bag onto the machine's infeed guide. The integrated conveyor belt automatically pulls the bag horizontally through the machine. As it travels, the bag is first vacuumed and/or flushed with gas (if these functions are activated), then guided between heated sealing bars that create a strong, consistent 13mm seal. Finally, the bag passes through the solid-ink coding station to be printed before exiting the machine, fully sealed and coded for traceability.

Our Commitment to Quality and Sustainability

Our bag sealing equipment is built with reliability and performance at its core. We use high-quality motors, durable heating elements, and robust electronic components to ensure a long service life and consistent, high-quality results. The machine's design is focused on operational efficiency and energy conservation. By providing a reliable vacuum sealer and gas flushing solution that extends product shelf life, we help our customers reduce food waste and contribute to more sustainable business practices.

Comprehensive Customer & Technical Support

Application Expertise: Our knowledgeable team is available to discuss your specific bag materials, products, and packaging goals to confirm that this continuous heat sealing machine is the ideal solution for your production line.

Full Technical Assistance: We provide detailed user manuals and video tutorials for setup, operation, and maintenance. Our support team is always ready to assist with any troubleshooting to ensure you maximize the machine's capabilities.

Spare Parts & Consumables: We maintain a full inventory of essential spare parts and consumables, including sealing belts, heating elements, and solid-ink rolls, available for fast delivery to keep your production running smoothly.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between the FRL600AS and FRL600BS models?

A: The primary difference is the total power consumption, which relates to the performance of the vacuum and heating elements. The FRL600BS model has slightly higher power, which may offer faster heat-up times or more robust vacuum performance, making it better suited for more demanding applications or thicker materials.

Q2: What is "gas flushing" and why would I need it for my product?

A: Gas flushing, or Modified Atmosphere Packaging (MAP), is a process where the air inside a package is replaced with an inert gas (like nitrogen) before sealing. This is crucial for perishable goods as it displaces oxygen, which in turn slows down oxidation and the growth of aerobic microorganisms, significantly extending the product's shelf life.

Q3: Is the conveyor height adjustable?

A: Yes, the distance of the conveyor from the sealing unit is adjustable between 120mm and 600mm. This flexibility allows you to easily accommodate a wide range of bag sizes and heights, from small pouches to larger stand-up bags.