ZDB-900-Q8 High-Speed Fully Automatic Bagging System

The Ultimate Solution for Automated Granular Packaging

Revolutionize your packaging line with our ZDB-900-Q8 fully automatic bagging equipment. Engineered for high-speed, precision performance, this system is ideal for packing a wide array of granular materials, including grains, sugar, beans, seeds, and pet food.

Leveraging advanced servo motor technology and world-class components, it provides an unparalleled level of efficiency, accuracy, and reliability, minimizing labor costs and maximizing your output.

Model: ZDB-900-Q8

Capacity: 550 - 900 bags/hour

Package Weight: 5 - 25 kg

Key Advantages of the ZDB-900-Q8

Intelligent Servo-Driven System

Major motorized actions are controlled by high-performance servo motors, allowing for rapid and precise adjustments for different packing specifications without manual intervention.

Continuous, Uninterrupted Operation

A double-station bag magazine holds up to 300 bags and features an alarm to ensure a seamless workflow, while faulty bags are automatically rejected without stopping production.

World-Class Component Integration

Built with globally recognized brands like Mettler Toledo, Schneider, SMC, and Newlong, guaranteeing superior reliability, longevity, and performance.

Flawless Bag Handling & Sealing

Advanced mechanisms like independent clamping systems, large finger cylinders for smooth mouth opening, and synchronized conveyors ensure perfect filling and sealing every time.

Technical Specifications

| Model | ZDB-900-Q8 |

| Packing Speed | 550 ~ 900 bags/hour |

| Package Weight | 5 ~ 25 kg |

| Applicable Bag Size (mm) | Length: 500-800, Width: 210-380 |

| Applicable Materials | Granular materials such as grains, rice, sugar, beans, seeds, etc. |

| Air Pressure / Consumption | 0.4 ~ 0.6 MPa / 15 m³/h |

| Power Requirements | 380/220V Three-phase five-wire, 6KW |

| Bag Storage Capacity | 100 ~ 300 pcs (depending on bag thickness) |

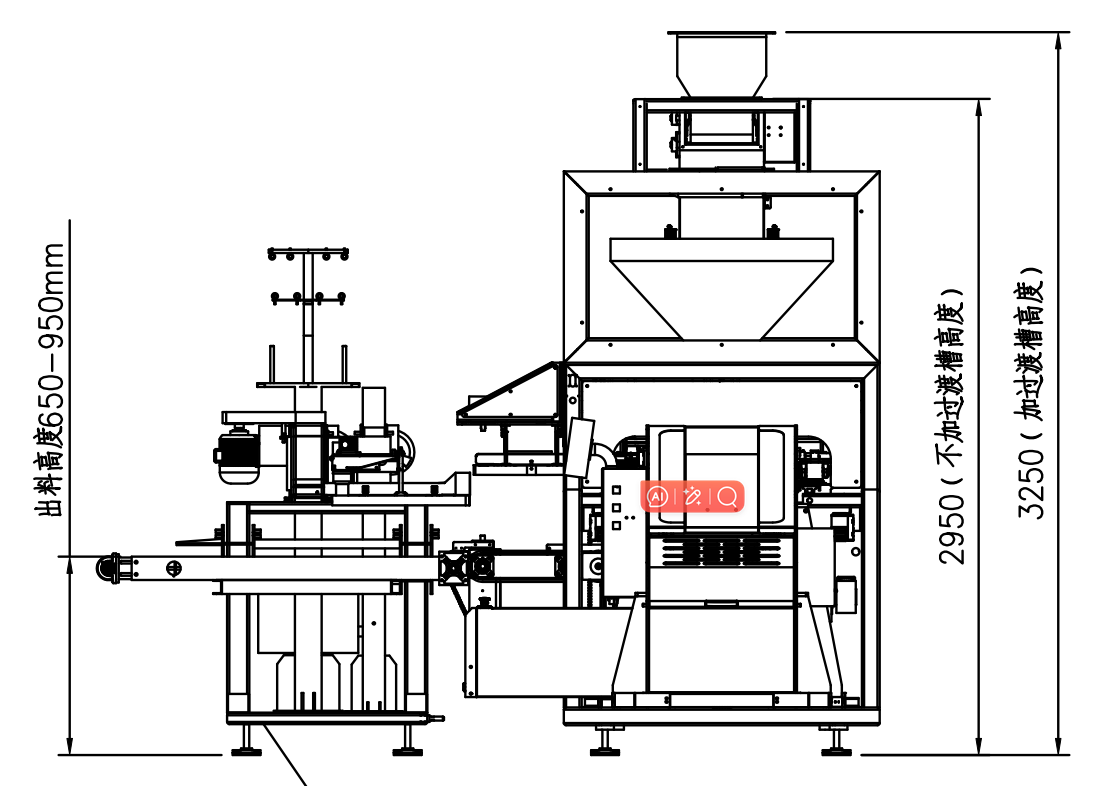

| Overall Dimensions (L×W×H, mm) | 3520 × 3257 × 3250 |

Ideal Application Scenarios

1

Grain & Food Processing

High-speed, hygienic packaging for rice, beans, sugar, pulses, and other bulk food products.

2

Agriculture & Seed Industry

Accurate weighing and packing of valuable seeds, grains, and specialty agricultural products.

3

Pet Food Manufacturing

Efficiently handles dry pet food (kibble), ensuring consistent package weights and presentation.

4

Chemicals & Resins

Suitable for packing non-corrosive granular chemicals, plastic pellets, and other industrial materials.

In-Depth Product Information

Commitment to Quality: Premium Component Configuration

The exceptional performance of the ZDB-900-Q8 is built upon a foundation of world-class components. This ensures maximum uptime, reliability, and precision across all functions. Our commitment to quality is evident in our choice of suppliers:

| Component | Brand/Origin |

| Weighing Controller (Touch Screen) | Switzerland / Mettler Toledo |

| Load Cells | USA / Celtron |

| Servo Motor | Japan / Panasonic |

| Electric/Pneumatic Cylinders | Japan / SMC, IAI; Taiwan / AirTac |

| Switches, Relays, Breakers | Japan / Omron; France / Schneider |

| Solenoid Valve | Taiwan / AirTac |

| Vacuum Pump | Germany / Leybold |

| Stitching Machine | Japan / Newlong DS-9CW |

Our Unwavering Commitment to You

Quality Manufacturing: Every machine undergoes a rigorous quality control process, from raw material inspection to final assembly and a 72-hour continuous test run before shipment to ensure flawless performance upon arrival.

Pre-Sales Consultation: Our technical team will work with you to understand your exact material and packaging requirements, offering customized solutions and detailed proposals to ensure a perfect fit for your operation.

Comprehensive After-Sales Service: We provide full installation guidance, operational training for your staff, a complete one-year warranty on all parts, and lifetime technical support to ensure your long-term success.

Frequently Asked Questions (FAQ)

Q: What types of bags is this automatic equipment compatible with?

A: The machine is highly versatile and designed to handle pre-made open-mouth bags, including paper bags, PP/PE woven bags, and composite film bags.

Q: How difficult is it to switch between different product weights or bag sizes?

A: Thanks to the advanced servo motor control system and touch-screen interface, changing parameters for different packaging specifications is fast and straightforward. Operators can easily recall pre-saved recipes, minimizing downtime.

Q: Can the machine handle dusty materials?

A: Yes, the system can be optionally equipped with a dust collection interface at the filling station to maintain a clean working environment when handling fine or dusty granular materials.