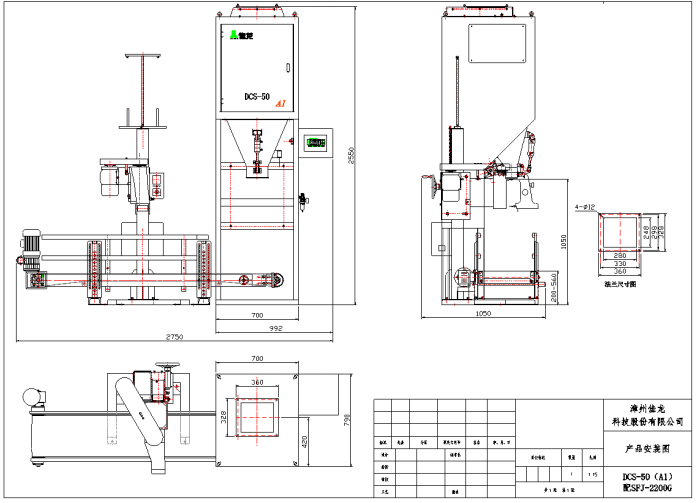

DCS-50-A1 Integrated Open Mouth Bagging Machine

DCS-50-A1 Semi-Automatic Open Mouth Bagging System

Streamline your packaging operations with the DCS-50-A1, an all-in-one open mouth bagging machine designed for efficiency and reliability. This turnkey system expertly handles a wide array of granular materials, from agricultural commodities to industrial powders and food products.

Integrating precision weighing, conveying, and automated bag sewing, this machine provides a cost-effective, semi-automatic solution that boosts productivity while ensuring consistent, high-quality packaging for every bag.

Model: DCS-50-A1

Capacity: 300 - 400 bags/hour

Core Technology: Integrated Weighing & Sewing

Key Advantages

Turnkey Integrated System

This open mouth bag packing machine combines a weighing scale, conveyor, and automated sewing head into one seamless unit, providing a complete packaging solution right out of the box.

Engineered for Precision

Featuring a proprietary controller and high-quality load cells, the system delivers Class X(0.2) accuracy, minimizing product giveaway and ensuring customer satisfaction.

Hygienic & Durable Construction

All material contact surfaces are constructed from polished 304 stainless steel with weld-free engineering to prevent bacterial growth and comply with HACCP standards.

Smart & Safe Operation

The AI-powered diagnostic system monitors 23 operational parameters to predict potential failures, while the machine is built into a rugged, IP66-rated frame for harsh environments.

Technical Specifications

| Parameter | Model: DCS-50-A1 |

| Weighing Range | 20 - 50 kg |

| Operation Speed | 300 - 400 bags/hour |

| Weighing Accuracy | Class X(0.2) |

| Scale Interval (Resolution) | 10 g |

| Power Requirement | 4N-AC 380V / 50Hz, 1 KW |

| Air Requirement | 0.4~0.6 MPa, 1 m³/hour |

| Installation Height | 2550 mm |

Main Component Configuration

| Component | Brand / Supplier |

| Weighing Controller | CN/Jialong |

| Low-Voltage Electricals (Button, etc.) | French/Schneider |

| Load Cell | ZEMIC |

| Power Switch | Taiwan/Meanwell |

| Pneumatic Elements (Cylinder, Solenoid Valve) | Taiwan/Airtac |

Diverse Application Scenarios

1

Agricultural Commodities

As a premier machine for packing rice in bags, it also efficiently handles other grains like wheat, millet, and corn with specialized flow control to prevent damage and ensure accuracy.

2

Food Processing Industry

Perfectly suited for bagging a wide variety of food-grade materials, such as sugar crystals and seasoning powders, utilizing hygienic, food-safe contact surfaces.

3

Industrial & Chemical Sector

The system reliably packages granular chemicals like fertilizers and industrial salts, incorporating anti-corrosion components for enhanced durability and safety.

4

Construction & Minerals

Designed with abrasion-resistant contact points, this open mouth bagging machine is capable of handling abrasive building materials such as cement, sand, and other fine aggregates.

In-Depth Details

Operational Workflow

The DCS-50-A1 provides a streamlined, semi-automatic workflow. An operator places an empty bag onto the filling spout and presses a foot pedal or button. The machine automatically clamps the bag, fills it to the precise target weight, and releases it onto the integrated conveyor. The conveyor then transports the bag to the automated sewing station, which applies a secure stitch and automatically cuts the thread. The entire cycle is designed to be fast, efficient, and ergonomic for the operator.

Jialong Technology: A Commitment to Innovation & Quality

With a legacy beginning in 2008, Jialong Technology stands as a pioneer in bulk material handling. Our expertise is built on field data from over 1,200 successful installations across 37 countries. The DCS-series represents our 3rd generation of packaging technology, incorporating 14 proprietary innovations, including the patented Jialong VFD Anti-Arch System™ for handling difficult materials. Our solutions are manufactured under a CE and ISO 9001:2015 certified quality management system, with GMP-compatible options available.

Turnkey Service and Lifecycle Support

Turnkey Integration: We offer a complete service cycle from initial site assessment and equipment customization to professional installation and comprehensive operator training.

Material-Specific Optimization: Our engineers have developed specialized adjustment protocols to optimize machine performance for a wide range of materials, including fine powders, flakes, and irregular granular products.

Lifecycle Management: We provide ongoing support through remote diagnostics and help clients with critical spare parts inventory planning to ensure maximum uptime and operational longevity.

Frequently Asked Questions (FAQ)

Q1: What does "Class X(0.2) accuracy" mean for my business?

A: This is an industry-standard accuracy rating that indicates a very high level of precision. For your business, it means you can trust that each bag is filled to the correct weight with minimal deviation. This reduces product giveaway, saves money over time, and ensures you meet regulatory and customer requirements.

Q2: Is this open mouth bag packing machine difficult to maintain?

A: No, it is designed for simplified service. It uses high-quality, long-lasting components from trusted global brands. Regular maintenance is straightforward, and the AI-powered diagnostic system helps predict potential issues before they cause downtime, allowing for proactive servicing.

Q3: Can this machine be integrated with an automated palletizer?

A: Absolutely. The machine for packing rice in bags and other products is designed with Industry 4.0 integration in mind. Its standard conveyor height and OPC-UA compliant interfaces allow it to seamlessly connect with downstream equipment like robotic or conventional palletizers to create a more fully automated end-of-line solution.